An energy saving biomass gasifying furnace

A gasifier and biomass technology, applied in incinerators, combustion methods, combustion types, etc., can solve problems such as air and water pollution, resource waste, pollution, etc., and achieve a large reduction in biomass and complete gasification and combustion. , the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

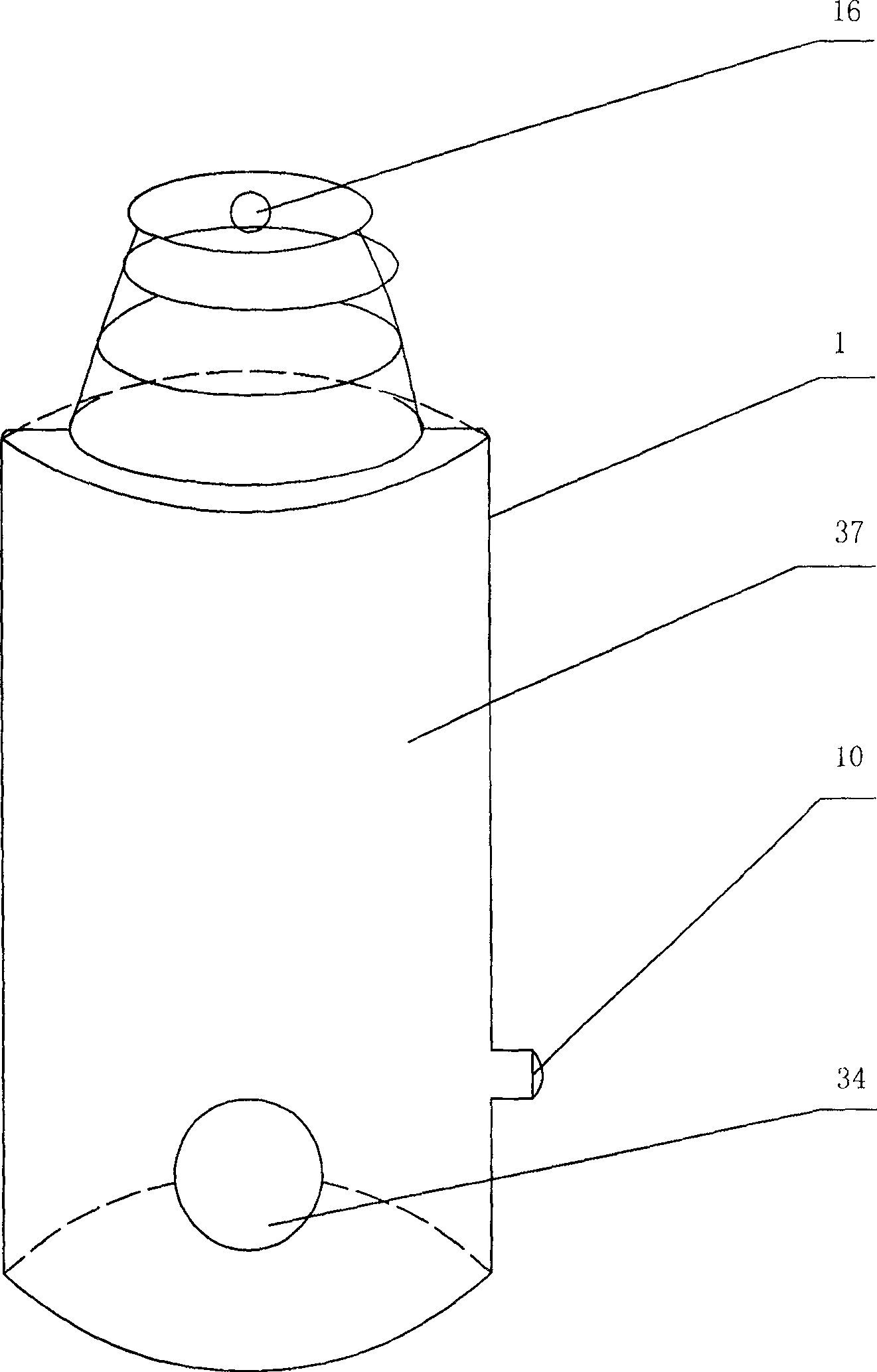

[0028] figure 1 It is a structural diagram of the present invention. In the figure, the feed port 16 of the present invention is arranged on the top of the furnace body 1, the furnace hearth 37 is in the furnace body 1, the slag outlet 34 is arranged on the bottom of the furnace body 1, and the furnace door 10 is arranged on the furnace body 1 on.

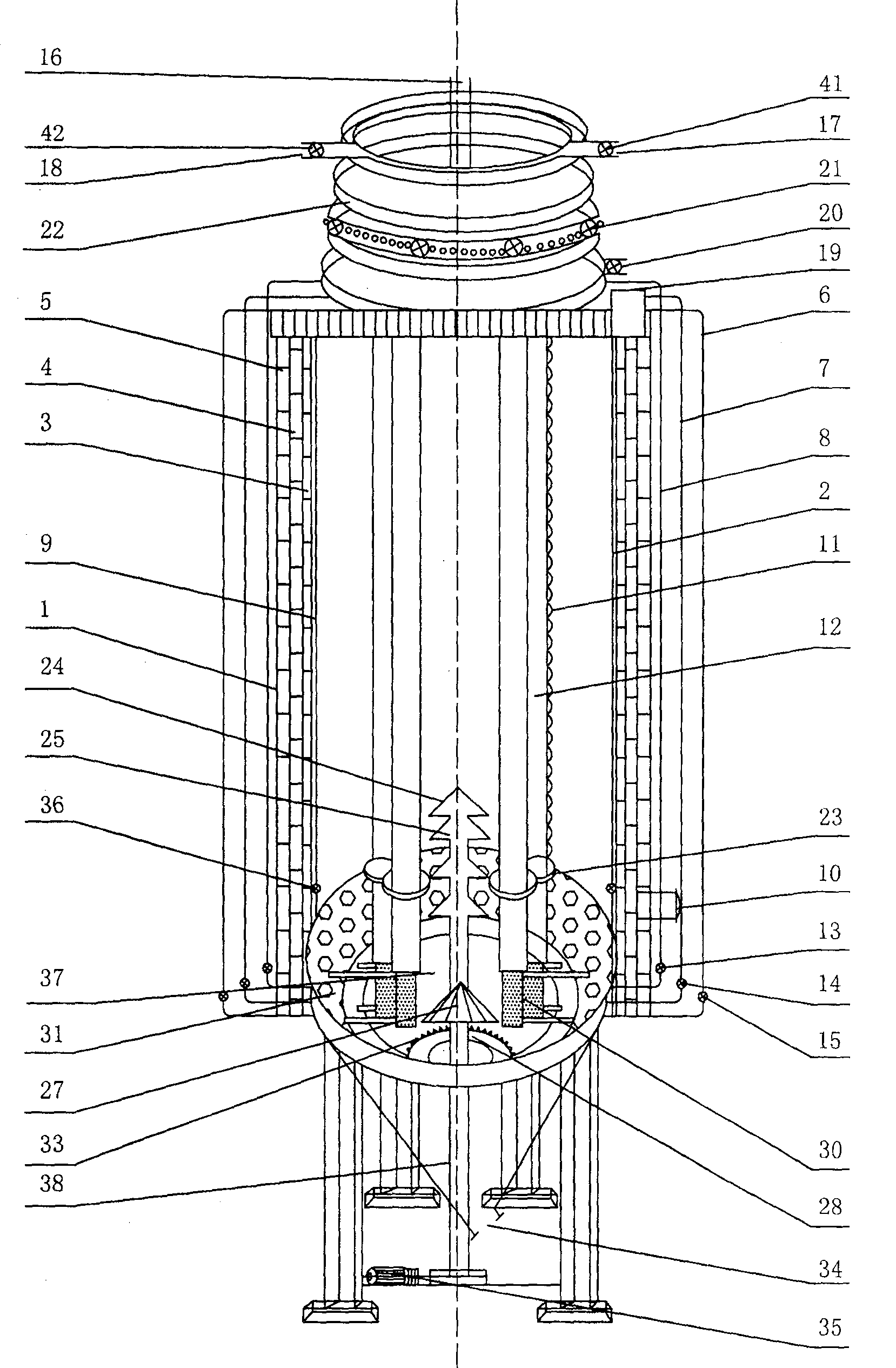

[0029] figure 2 It is a cross-sectional view of the present invention. In the figure, the present invention includes a spiral smoke box 22 arranged on the top of the furnace body 1, an electric distribution device 28 arranged in the furnace 37, a steam pipe 2, four secondary combustion fire pipes 12 and three Three air inlet pipes, that is, the three air inlet pipes are respectively the primary air inlet pipe 6, the secondary air inlet pipe 7, and the third air inlet pipe 8. The steam pipe 2 is provided with an electric valve 36, the primary air inlet pipe 6, and the secondary air inlet pipe. Electric valves 15, 14, and 13 are r...

Embodiment 2

[0042] The difference between this embodiment and the first embodiment is that there are twelve secondary combustion fire tubes 12 in this embodiment, and the effects achieved by this embodiment and the first embodiment remain the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com