Modified aluminium phosphate molecular sieve and preparation method thereof

An aluminum phosphate molecular sieve and molecular sieve technology, applied in the field of molecular sieves, can solve the problems of ZSM-5 molecular sieves such as unsatisfactory hydrothermal stability, adsorption performance and cracking performance, and achieve excellent adsorption performance and cracking performance, small particle size and complete crystallization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

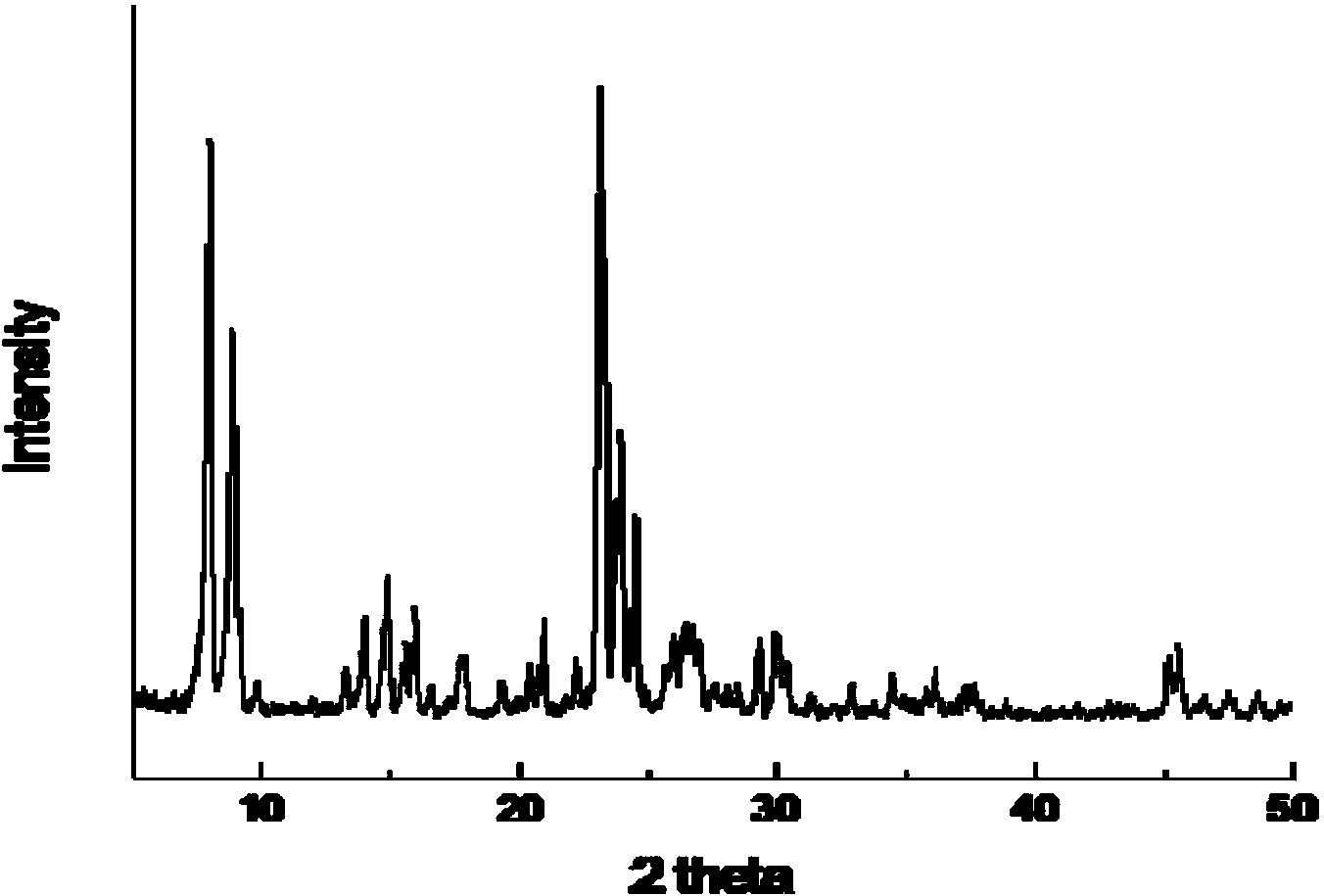

[0024] In parts by weight, add 1 part of ZSM-5 molecular sieve to 4 parts of purified water, add 0.50 parts of diammonium hydrogen phosphate and 0.008 parts of zinc nitrate solution in the purified water, stir for 35min-40min, then heat up to 140°C, pressure control At 0.30MPa, stir for 140min to complete the exchange reaction, then filter and dry; finally roast at 560°C for 2h to obtain a modified aluminum phosphate molecular sieve of the present invention, its structure is as follows: figure 1 The scanning electron microscope image and figure 2 shown in the crystal phase diagram.

Embodiment 2

[0026] In parts by weight, add 1.5 parts of ZSM-5 molecular sieve to 5 parts of purified water, add 0.48 parts of diammonium hydrogen phosphate and 0.010 parts of zinc nitrate solution in the purified water, stir for 30min-35min, then heat up to 130°C, pressure control At 0.38MPa, stir for 150min to complete the exchange reaction, then filter and dry; finally roast at 590°C for 2h to obtain a modified aluminum phosphate molecular sieve of the present invention, whose structure refers to figure 1 The scanning electron microscope image and figure 2 crystal phase diagram.

Embodiment 3

[0028] In parts by weight, add 0.5 parts of ZSM-5 molecular sieve to 3 parts of purified water, add 0.52 parts of diammonium hydrogen phosphate and 0.010 parts of zinc nitrate solution in the purified water, stir for 30min-35min, then heat up to 150°C, pressure control At 0.18MPa, stir for 130min to complete the exchange reaction, then filter and dry; finally roast at 590°C for 2h to obtain a modified aluminum phosphate molecular sieve of the present invention, whose structure refers to figure 1 The scanning electron microscope image and figure 2 crystal phase diagram.

[0029] Example of application effect

[0030] Take 6 parts of the modified molecular sieves prepared in Examples 1-3 and put them into a ball mill to form small balls, intermittently spray the mixture of 5 parts of aluminum sol solution and 1 part of deionized water, and then dry at 140°C for more than 5 hours, Calcined at 400-600°C for 2-8 hours to obtain the catalyst.

[0031] When the reaction temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com