Novel ceramic coating polyolefin composite film and preparation method thereof

A technology of ceramic coating and polyolefin, which is applied in the field of preparation of the composite film, can solve problems such as bad gas and side effects of lithium-ion batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

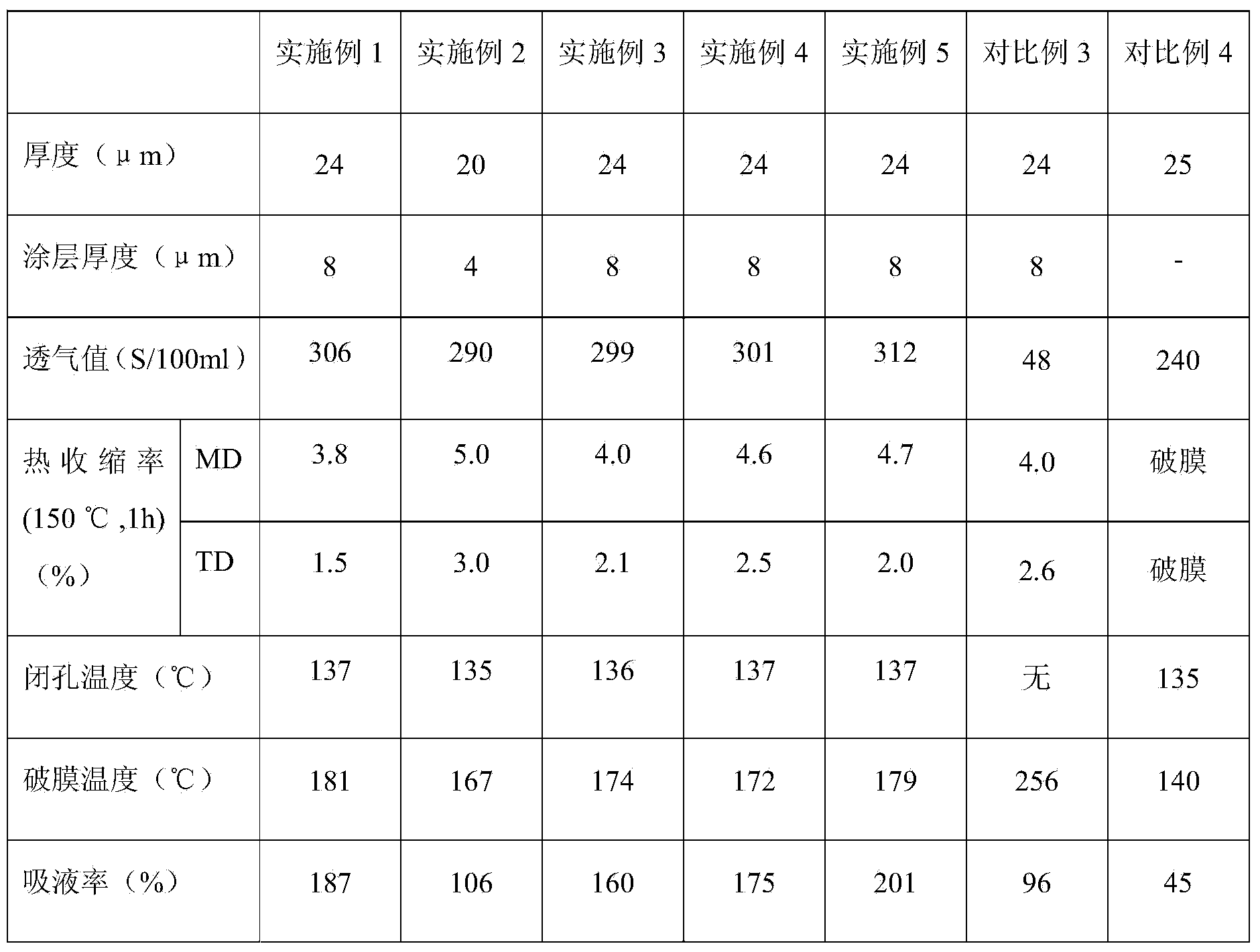

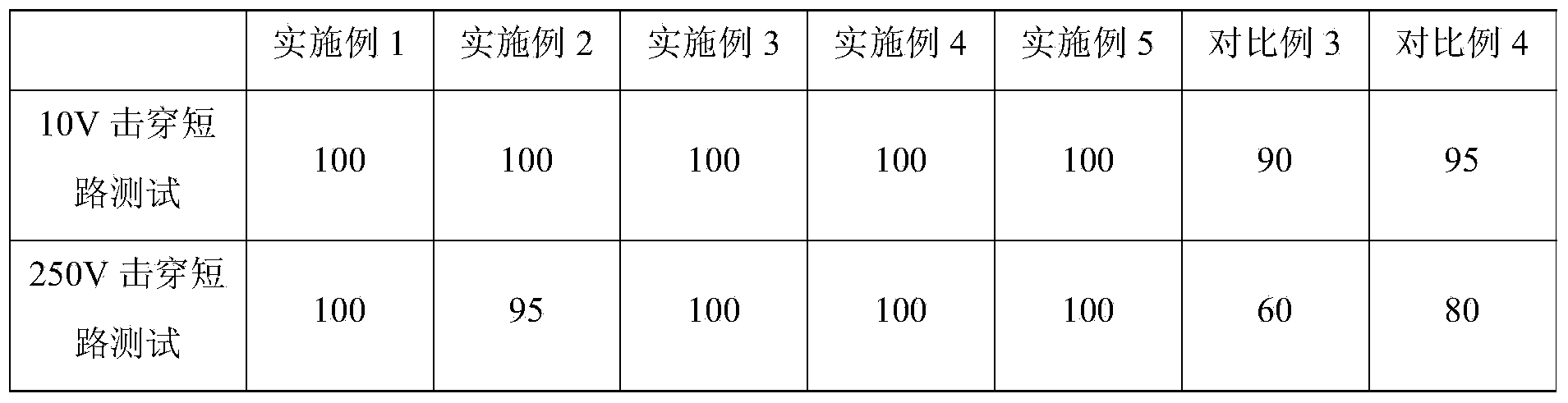

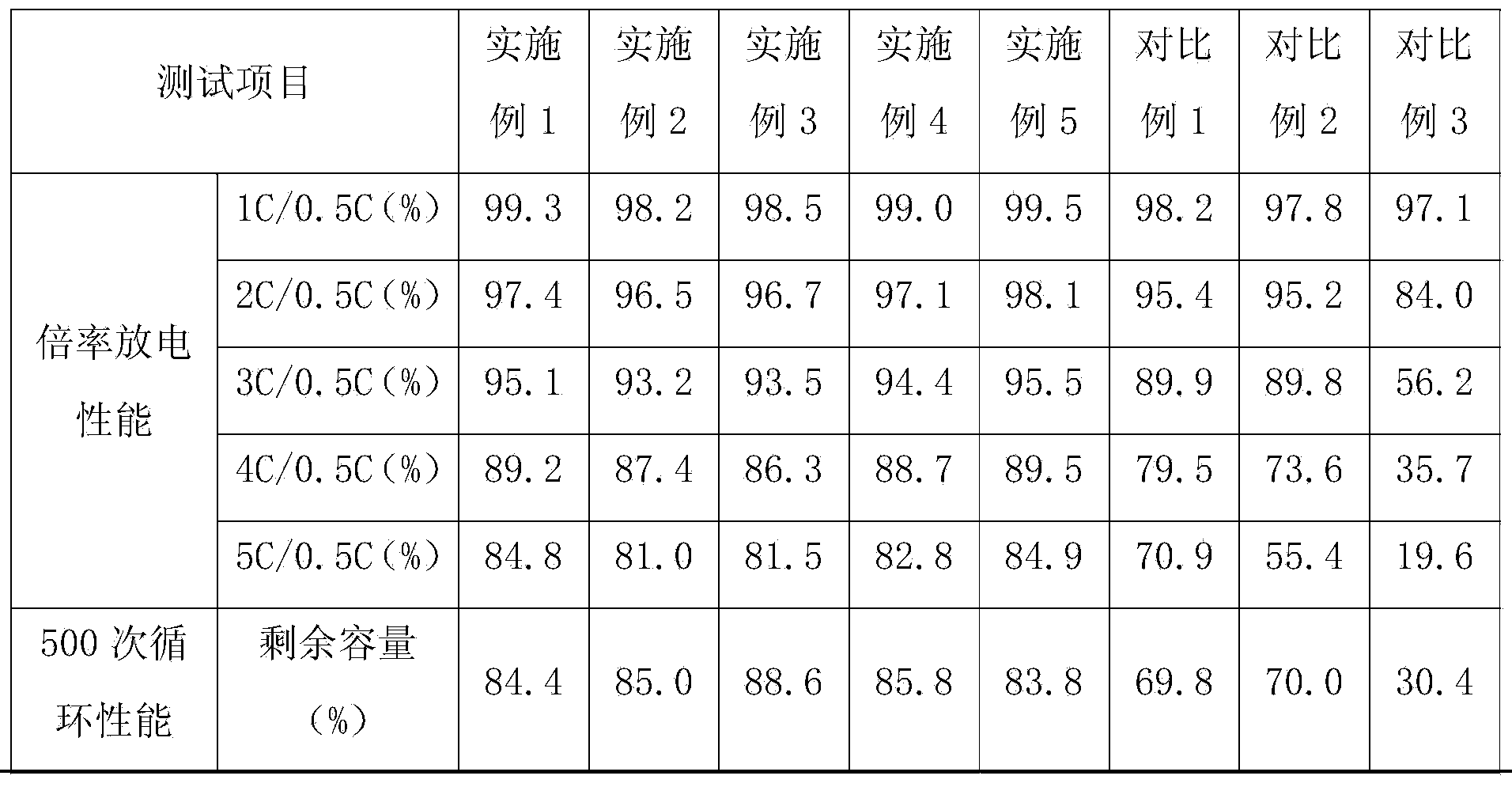

Examples

Embodiment 1

[0045] 35 parts by weight of glass powder (average particle size 0.6μm), 55 parts by weight of alumina (average particle size 0.8μm, specific surface area of about 15m 2 / g), 8 parts by weight of styrene-butadiene latex and 120 parts by weight of water were mixed, dispersed for (2-3) hours, and left to stand for defoaming (1-2) hours to obtain a coating liquid.

[0046] Choose 16μm ultra-high molecular weight polyethylene-based membrane (referred to as UHMWPE, the same below), with an average pore size of 40-65nm, a porosity of 40%, an air permeability of 200s / 100ml, 105°C, 1h heat shrinkage in the MD direction of 2.1%, , TD direction is 0.6%, puncture strength is 650g. Use the photosensitizer benzophenone to pretreat the surface of UHMWPE, and irradiate the surface of UHMWPE with ultraviolet rays with a wavelength of 290nm to make the surface cross-linked, and then the benzophenone can also be sublimated and removed without residue.

[0047] The above coating solution was ...

Embodiment 2

[0049] The multilayer composite microporous membrane was prepared according to the method of Example 1, except that it was coated on one surface of the UHMWPE base membrane, that is, the total thickness of the coating was 4 μm.

Embodiment 3

[0051] The multilayer composite microporous membrane was prepared according to the method of Example 1, except that 20 parts by weight of glass powder (average particle size 0.6 μm) was used instead of 35 parts by weight of glass powder (average particle size 0.6 μm), and 70 parts by weight parts of alumina (average particle size 0.8μm, specific surface area about 15m 2 / g) instead of 55 parts by weight of alumina (average particle size 0.8μm, specific surface area about 15m 2 / g).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com