A kind of multi-component polymer resin and petroleum asphalt blend material and prepared waterproof membrane

A technology of polymer resin and petroleum asphalt, which is applied in the direction of building insulation materials, asphalt layered products, synthetic resin layered products, etc., can solve the problems of puncture resistance, cyclic load resistance, low bonding performance, low temperature flexibility and Insufficient low-temperature strength and insufficient low-temperature resistance to achieve strong puncture resistance and cyclic load bearing, improved toughness, and reliable waterproof function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

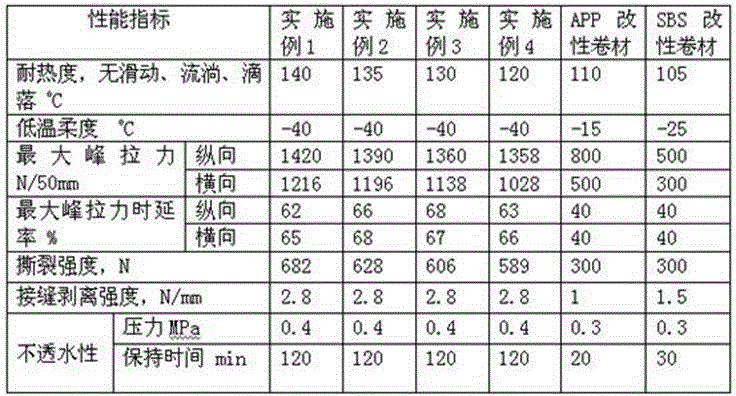

Examples

Embodiment 1

[0041] A kind of multi-component polymer resin and petroleum asphalt blend material, its composition and mass parts are: PE-RT, 100 parts; SIS, 120 parts; C5 petroleum resin, 40 parts; Machine oil, 70 parts; Mineral powder, 150 parts parts; asphalt, 480 parts;

[0042] Substrate: 300g / m 2 Long staple polyester nonwoven.

[0043] The preparation method of multi-component organic polymer resin and asphalt blend material comprises the following steps:

[0044] (1) According to the components and mass ratio of the blended material, add asphalt and engine oil into a heated and stirred tank, raise the temperature to 170°C, add C5 petroleum resin, and start stirring after 30 minutes of static penetration;

[0045] (2) Heat up to 185°C, add SIS, stir for 90 minutes, grind in a colloid mill, grind three times in an open cycle, and continue stirring to obtain the base material;

[0046] (3) In the single-screw thermoplastic extruder, the preset temperature is 110°C in zone I and 130°...

Embodiment 2

[0057] A kind of multi-component polymer resin and petroleum asphalt blend material, its composition and mass parts are: PE-RT, 80 parts; SIS resin, 130 parts; C5 petroleum resin, 40 parts; Machine oil, 70 parts; Mineral powder, 150 parts; asphalt, 480 parts; tire base: 300 g / m 2 Long staple polyester nonwoven.

[0058] The preparation method of the blended material and the waterproof membrane are the same as in Example 1.

Embodiment 3

[0060] A kind of multi-component polymer resin and petroleum asphalt blend material, its composition and mass parts are: PE-RT, 70 parts; SIS resin, 140 parts; C5 petroleum resin, 40 parts; Machine oil, 70 parts; Mineral powder 150 parts parts, asphalt, 480 parts; tire base, 300 g / m 2 Long staple polyester nonwoven.

[0061] The preparation method of the blended material and the waterproof membrane are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com