Novel technology for preparing ortho-aminophenol

A technology of o-aminophenol and o-nitrochlorobenzene, which is applied in the chemical industry, can solve the problems of low product yield, high cost of ethanol, and high cost, and achieve the effects of high conversion rate of finished products, expansion of production income, and improvement of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

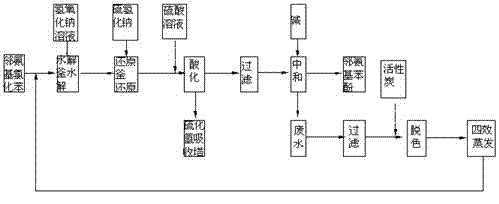

[0027] A novel process for preparing o-aminophenol is characterized in that: it specifically comprises the following steps:

[0028] 1. (1) Select a certain amount of o-nitrochlorobenzene as a raw material.

[0029] (2) Add o-nitrochlorobenzene into the sodium hydroxide solution and enter the hydrolysis kettle for hydrolysis. The hydrolysis temperature is 160~175°C

[0030] The reaction time is 4.5 hours, and the pressure is 0.68MP~0.72MP.

[0031] (3) Sodium o-nitrophenolate is obtained through hydrolysis in a hydrolysis kettle.

[0032] (4) Pour the obtained product into a reduction kettle and add sodium hydrosulfide for reduction to obtain sodium o-aminophenate. The reduction temperature is 60-80°C and the reduction time is 4-5 hours.

[0033] (5) Add sulfuric acid solution for acidification, so that the solution remains acidic, the pH value is controlled between 3 and 5, and sulfur element is precipitated.

[0034] (6) Filter.

[0035] (7) Add alkali to the filtered so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com