Ocean thermal energy open cycle power generation system

An open cycle and power generation system technology, applied in ocean energy power generation, machines/engines, mechanical equipment, etc., can solve the problems of net power generation reduction, low heat exchanger efficiency, manufacturing difficulties, etc., and achieve single machine power increase, The effect of reducing manufacturing cost and reducing the amount of exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

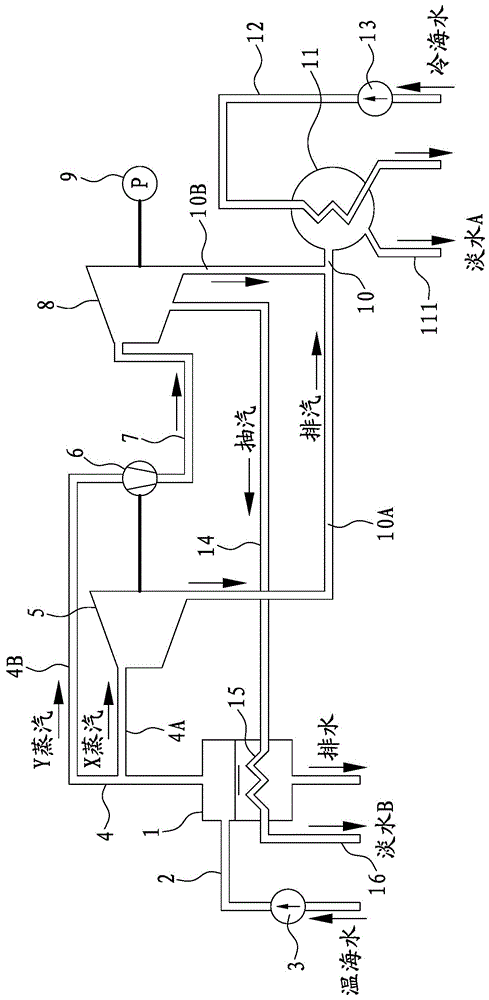

Embodiment 1

[0018] Such as figure 1 Shown is the first embodiment of the ocean thermal open cycle power generation system of the present invention, which is based on the simplest form of an ocean thermal open cycle power generation system with a single front small steam turbine and a single main steam turbine, which includes a flash Evaporator 1, warm seawater pipeline 2, warm seawater pump 3, low-pressure steam pipeline 4, front small steam turbine 5, steam compressor 6, high-pressure steam pipeline 7, main steam turbine 8, generator 9, exhaust pipeline 10, surface condenser 11. Cold seawater pipeline 12, cold seawater pump 13, steam extraction pipeline 14, heat exchange tube bundle 15, fresh water outlet pipeline 16.

[0019] The seawater inlet of the flash evaporator 1 is connected to a warm seawater pipeline 2 and a warm seawater pump 3 is arranged on the warm seawater pipeline 2 , and the steam outlet of the flash evaporator 1 is connected to a low-pressure steam pipeline 4 .

[002...

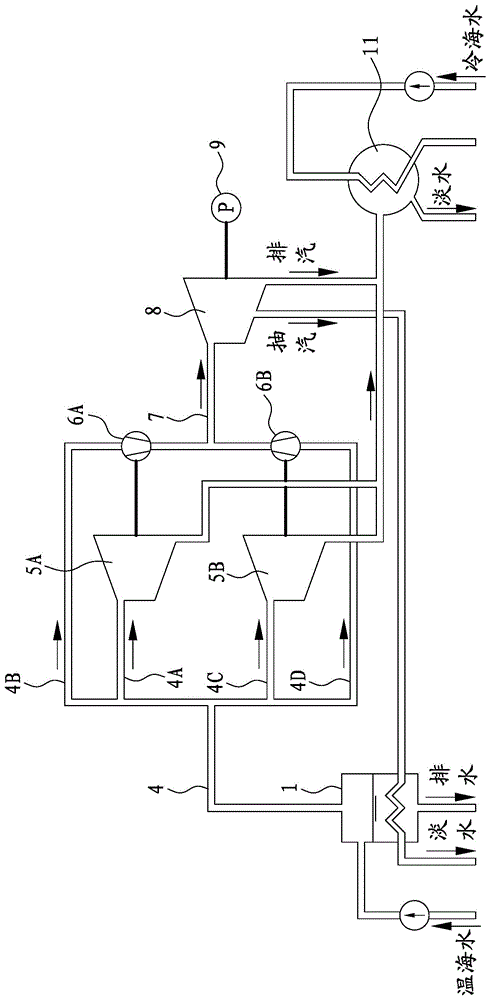

Embodiment 2

[0030] Such as figure 2As shown, it is the second embodiment of the ocean thermal open cycle power generation system of the present invention, which is an open cycle power generation of ocean thermal energy with two front small steam turbines and a single main steam turbine evolved according to the working principle of the present invention system. The low-pressure steam pipeline 4 of the system is divided into four branch pipes 4A, 4B, 4C, and 4D: the low-pressure steam branch pipe 4A is connected to the steam inlet of the front small steam turbine 5A, and the low-pressure steam branch pipe 4B is connected to the steam inlet of the steam compressor 6A; the front small steam turbine 5A is coaxially connected with the steam compressor 6A; the low-pressure steam branch pipe 4C is connected with the steam inlet of the small steam turbine 5B in front, and the low-pressure steam branch pipe 4D is connected with the steam inlet of the steam compressor 6B; the small steam turbine 5B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com