Thermoplastic polyether ester elastomer composition as well as preparation method and application thereof

A thermoplastic polyetherester and polyetherester elastomer technology, applied in the field of thermoplastic polyetherester elastomer composition and its preparation, can solve the problem that polyetherester elastomers cannot meet the requirements of low price, high quality, low tensile strength, Insufficient resilience and other problems, to achieve the effect of improving processing performance and mechanical properties, high elongation at break, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] Preparation of polycaprolactone polyol (B-PCL):

[0050] Heat a clean and dry four-necked flask in an oil bath at 120°C, and at the same time pass nitrogen to remove impurities such as moisture and oxygen in the flask; raise the temperature of the oil bath to 140°C~160°C, and add caprolactone monomer , Initiator trimethylolpropane or pentaerythritol and catalyst butyl titanate, under nitrogen protection, temperature control and stirring reaction for 6 h ~ 8 h, stop heating, continue stirring with nitrogen, stop when the temperature of the reactant drops below 60 °C The reacted polycaprolactone is cooled under the protection of nitrogen, dissolved in chloroform, reprecipitated with methanol, vacuum-dried at 40°C after suction filtration, and the number-average molecular weight is 2000.

[0051] Synthesis of polyetherester elastomer (TPEE):

[0052] According to the formula shown in Table 1, add DMT, BDO and B-PCL, polytetrahydrofuran diol (Mn=1000) into the reaction ...

Embodiment 1-9、 comparative example 1-3

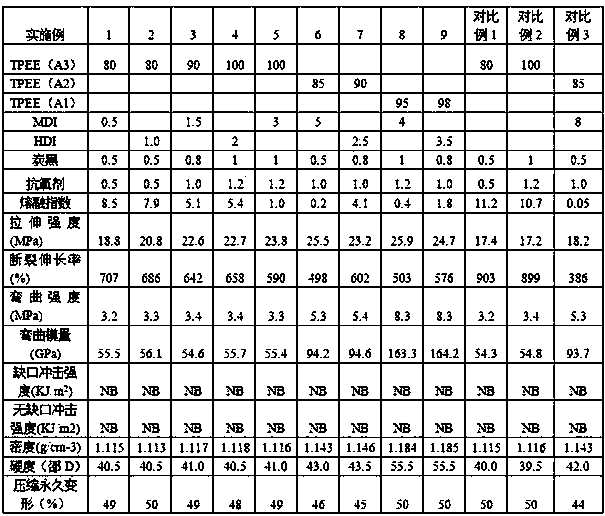

[0056] According to the proportions of the components shown in Table 2, add TPEE, isocyanate compounds, antioxidants, processing aids, etc. Extruded and granulated to obtain thermoplastic elastomer TPEE modified material, the performance test results are shown in Table 2.

[0057] Table 2 embodiment 1-9 and comparative example 1-3 concrete proportioning and test performance result

[0058]

[0059] From the comparison of the results of Example 1 and Comparative Example 1, Example 4 and Comparative Example 2, it can be seen that adding a small amount of MDI or TDI to the polyetherester elastomer can significantly reduce the melt index of the composition and improve the tensile strength of the material. Tensile strength, its elongation at break is also more appropriate, and has better resilience.

[0060] From the comparison of Example 6 and Comparative Example 3, it can be seen that the addition of excessive isocyanate compounds in Comparative Example 3 greatly reduces the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com