Preparation method of surface imprinting adsorbent for identifying ciprofloxacin at high sensitivity

A technology of ciprofloxacin and surface imprinting, applied in chemical instruments and methods, and other chemical processes, can solve the problem of poor adsorption-desorption kinetics, deep embedding of active sites, mass transfer and charge transfer Kinetic rate is slow and other problems, to achieve significant separation effect, reduce non-specific adsorption, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

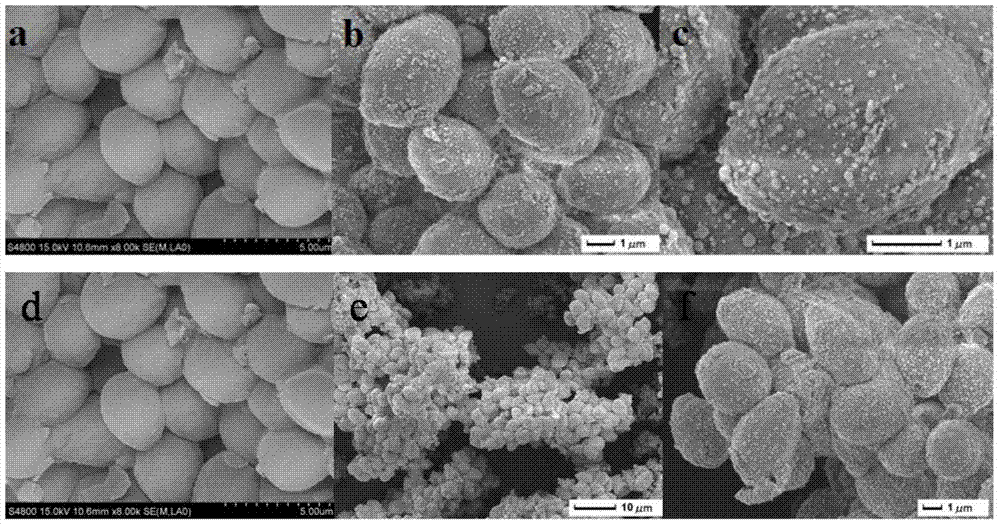

[0031] (1) Preparation of ciprofloxacin surface imprinted polymers (MIPs)

[0032] Put 0.2 g of active dry yeast into a 100 ml round-bottomed flask, add 10 ml of water, mix until the yeast dissolves, then add 40 ml of acetonitrile, sonicate for 10 min, then add ciprofloxacin 0.0625 mmol, acrylamide 0.25 mmol, 1 mmol of ethylene glycol bis(methacrylate) ester, mix and stir, pass nitrogen for 15 min, then carefully add 0.0043 g of 2,2'-azobisisobutyronitrile, seal the bottle mouth, and put it in a water bath In the shaker, set the temperature at 50°C and rotate at 180 rpm, react for 2 hours, then increase the temperature to 60°C, and continue the reaction for 22 hours. Then centrifuge and dry under vacuum at 60°C for 12 h. The synthesized product was Soxhlet extracted with a mixture of 90 mL methanol and 10 mL acetic acid for 48 h to remove the template molecule ciprofloxacin. Finally, ciprofloxacin surface-imprinted polymer was obtained by vacuum drying at 50°C for 6 h.

[0...

Embodiment 2

[0042] (1) Preparation of ciprofloxacin surface imprinted polymers (MIPs)

[0043] Put 0.15 g of active dry yeast into a 100 ml round bottom flask, add 10.5 ml of water, mix until the yeast dissolves, then add 42 ml of acetonitrile, ultrasonicate for 10 min, then add ciprofloxacin 0.05 mmol, acrylamide 0.3 mmol, 1.5 mmol of ethylene glycol bis(methacrylate) ester, mix and stir, pass nitrogen for 15 min, then carefully add 0.0096 g of 2,2'-azobisisobutyronitrile, seal the bottle mouth, and put it in a water bath In the shaker, set the temperature at 50°C, rotate at 180 rpm, react for 2 h, and increase the temperature to 60 oC , continue to react for 22 h. Then centrifuge and dry under vacuum at 60°C for 12 h. The synthesized product was Soxhlet extracted with a mixture of 90 mL methanol and 10 mL acetic acid for 48 h to remove the template molecule ciprofloxacin. Finally, ciprofloxacin surface-imprinted polymer was obtained by vacuum drying at 50°C for 6 h.

[0044] The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com