Micro-filtration membrane for filtering PM2.5 particulate matters and preparation method of membrane

A PM2.5 and particulate matter technology, applied in the field of microfiltration membranes for filtering PM2.5 particulate matter and its preparation, can solve the problems of uneven pore size distribution of materials, unsuitable for PM2.5 particulate matter filtration, and excessive pore size, to avoid Inconsistent filtering effect, avoiding uneven pore size distribution and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: PTFE powder and sherwood oil are mixed evenly according to the ratio of mass ratio 10:3, and the pasty mixture after mixing is extruded into PTFE base belt through die; Heat PTFE base belt to 250oC and continue 5 minutes, lubricate The agent is released; heat the PTFE base tape to 335oC and keep it for 45 seconds to obtain a continuous semi-sintered film with a sintering degree of 0.4; lower the temperature to 315oC, and stretch the film simultaneously or continuously at a rate of 100% / s, and the transverse stretching ratio is 5 times , the longitudinal stretching ratio is 6 times; the stretched PTFE film is kept at 350oC for 3 minutes for heat setting; finally, the PTFE film and the support layer are subjected to high-temperature hot-compression lamination.

Embodiment 2

[0034] Embodiment 2: PTFE powder and sherwood oil are mixed evenly according to the ratio of mass ratio 10:2, the pasty mixture after mixing is extruded through die and made PTFE base belt; Heating PTFE base belt to 250oC and continued 5 minutes, lubricated The agent is released; heat the PTFE base tape to 330oC and keep it for 50 seconds to obtain a continuous semi-sintered film with a sintering degree of 0.5; lower the temperature to 320oC, and stretch the film simultaneously or continuously at a rate of 100% / s, and the transverse stretching ratio is 1.5 times , the longitudinal stretching ratio is 15 times; the stretched PTFE film is kept at 350oC for 3 minutes for heat setting; finally, the PTFE film and the support layer are subjected to high-temperature hot-compression lamination.

Embodiment 3

[0035] Embodiment 3: PTFE powder and sherwood oil are mixed evenly according to the ratio of mass ratio 10:3.5, and the pasty mixture after mixing is extruded through die to make PTFE base belt; Heat PTFE base belt to 250 ℃ and continue 5 minutes, lubricate The agent is released; heat the PTFE base tape to 340oC and keep it for 40 seconds to obtain a continuous semi-sintered film with a sintering degree of 0.4; cool down to 310oC, and stretch the film simultaneously or continuously at a rate of 100% / s, and the transverse stretching ratio is 3 times , the longitudinal stretching ratio is 10 times; the stretched PTFE film is kept at 350oC for 3 minutes for heat setting; finally, the PTFE film and the support layer are subjected to high-temperature hot-compression lamination.

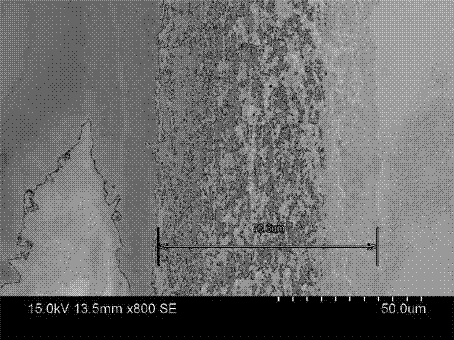

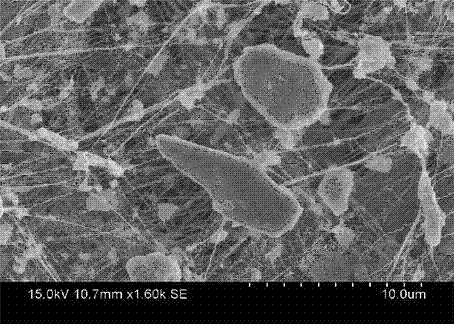

[0036] The main technical indicators of the prepared membrane are:

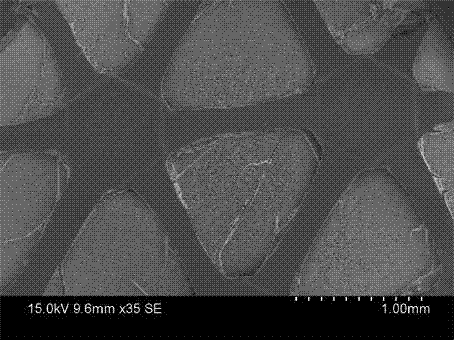

[0037] 1. Aperture size:

[0038] By using the bubble point method to measure the maximum pore size of the membrane, the maximum pore s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com