Preparation method of silver-loaded mesoporous inorganic antibacterial agent

An inorganic antibacterial agent and mesoporous technology, which is applied in the field of preparation of silver-loaded mesoporous inorganic antibacterial agents, can solve the problems of poor chemical stability and thermal stability, poor stability and heat resistance, and short drug effect duration, etc., to achieve Broad-spectrum antibacterial properties, stable antibacterial performance, and easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

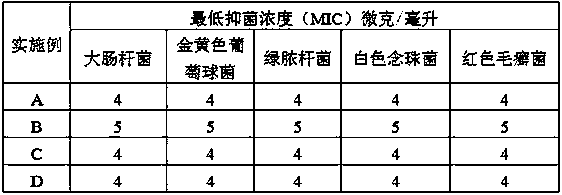

Examples

Embodiment 1

[0018] (1) Mix polyethylene glycol-polypropylene glycol-polyethylene glycol block copolymer and water uniformly according to the mass percentage of 0.01:1, stir until clear, then add n-butyl titanate and silver nitrate, of which n-titanate The mass percent of butyl ester and polyethylene glycol-polypropylene glycol-polyethylene glycol block copolymer is 0.1:1, and the mass percent of silver nitrate and polyethylene glycol-polypropylene glycol-polyethylene glycol block copolymer is 0.05:1, stirred at 200 rpm for 12 hours, then heated to 50°C, and continued to stir for 6 hours to obtain silver sol;

[0019] (2) Stir the silver sol solution at 300 rpm for 6 hours, and add dropwise an aqueous solution of sodium carbonate with a mass percent concentration of 0.01% in the stirring process until the mol ratio of silver ions and carbonate radicals in the sol solution is 2:1, to obtain titanium dioxide / silver carbonate gel;

[0020] (3) After the titanium dioxide / silver carbonate gel ...

Embodiment 2

[0023] (1) Mix sodium dodecylbenzenesulfonate and water uniformly according to the mass percentage of 0.2:1, stir until clear, then add isopropyl titanate and silver nitrate, wherein isopropyl titanate and dodecylbenzene The mass percentage of sodium sulfonate is 0.5:1, the mass percentage of silver nitrate and sodium dodecylbenzene sulfonate is 0.2:1, stir at 400 rpm for 6 hours, then heat to 80°C, and continue stirring for 2 hours , to obtain silver sol solution;

[0024] (2) Stir the silver sol solution at 500 rpm for 2 hours, and add dropwise an aqueous potassium carbonate solution with a mass percent concentration of 0.01% in the stirring process until the mol ratio of silver ions and carbonate radicals in the sol solution is 2:1, to obtain titanium dioxide / silver carbonate gel;

[0025] (3) After the titanium dioxide / silver carbonate gel was vacuum-dried, it was heat-treated at 800° C. for 2 hours to obtain a silver-loaded mesoporous inorganic antibacterial agent.

[0...

Embodiment 3

[0028] (1) Mix cetyltrimethylammonium bromide and water uniformly according to the mass percentage of 0.1:1, stir until clear, then add ethyl titanate and silver nitrate, wherein ethyl titanate and cetyl trimethylammonium The mass percentage of methyl ammonium bromide is 0.2:1, the mass percentage of silver nitrate and cetyl trimethyl ammonium bromide is 0.1:1, stirred at 350 rpm for 7 hours, then heated to 60°C, Continue stirring for 5 hours to obtain silver sol solution;

[0029] (2) Stir the silver sol solution at 350 rpm for 5 hours, and add dropwise an aqueous ammonium carbonate solution with a mass percent concentration of 0.01% in the stirring process until the mol ratio of silver ions and carbonate radicals in the sol solution is 2:1, to obtain titanium dioxide / silver carbonate gel;

[0030] (3) After the titanium dioxide / silver carbonate gel was vacuum-dried, it was heat-treated at 700° C. for 4 hours to obtain a silver-loaded mesoporous inorganic antibacterial agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com