Spinel structural infrared radiation material doped with rare-earth element and preparation method

A spinel structure and infrared radiation technology, which is applied in the field of infrared radiation materials, can solve the problems of large energy consumption, long preparation cycle, and application limitations of infrared radiation materials, achieve low sintering temperature, short preparation cycle, and facilitate popularization and application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

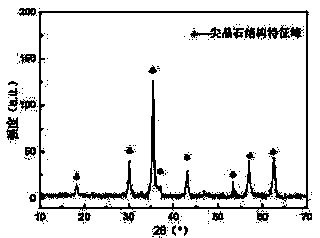

Embodiment 1

[0024] A preparation method of a spinel structure infrared radiation material doped with rare earth elements, the chemical composition formula of which is CoFe 1.7 Y 0.2 La 0.1 o 4 ,Proceed as follows:

[0025] 1) Put 2.910g of cobalt nitrate, 6.868g of iron nitrate, 0.766g of yttrium nitrate and 0.433g of lanthanum nitrate in a container, add 30ml of deionized water, and stir at room temperature for 5 minutes to fully dissolve the raw materials in deionized water;

[0026] 2) Add 6.3g of analytically pure citric acid as a complexing agent, and continue stirring at room temperature until the citric acid is completely dissolved;

[0027] 3) Add dropwise ammonia water with a concentration of 30 wt% to adjust the pH value of the solution to 5;

[0028] 4) Stir in a water bath at 80°C until a gel is formed;

[0029] 5) Dry the gel in an oven at 100°C for 5 hours to obtain a xerogel;

[0030] 6) Ignite at any point of the xerogel to produce self-propagating combustion until a...

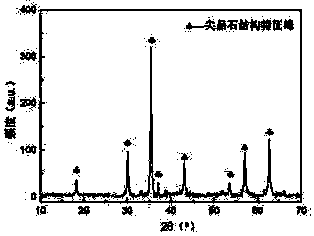

Embodiment 2

[0036] A preparation method of a spinel structure infrared radiation material doped with rare earth elements, its chemical composition formula is Co 0.4 Cu 0.6 Fe 1.8 Y 0.2 o 4 ,Proceed as follows:

[0037] 1) Put 1.164g of cobalt nitrate, 1.128g of copper nitrate, 7.272g of ferric nitrate and 0.766g of yttrium nitrate in a container, add 30ml of deionized water, and stir at room temperature for 5 minutes to fully dissolve the raw materials in deionized water;

[0038] 2) Add 6.3g of analytically pure citric acid as a complexing agent, and continue stirring at room temperature until the citric acid is completely dissolved;

[0039] 3) Ammonia water with a concentration of 30 wt% was added dropwise to adjust the pH value of the solution to 6;

[0040] 4) Stir in a water bath at 80°C until a gel is formed;

[0041] 5) Dry the gel in an oven at 110°C for 4 hours to obtain a xerogel;

[0042] 6) Ignite at any point of the xerogel to produce self-propagating combustion until...

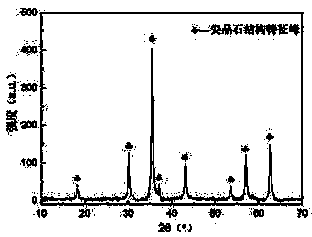

Embodiment 3

[0048] A preparation method of a spinel structure infrared radiation material doped with rare earth elements, the chemical composition formula of which is CoFe 1.8 Y 0.2 o 4 ,Proceed as follows:

[0049] 1) Put 2.91g of cobalt nitrate, 7.272g of iron nitrate and 0.766g of yttrium nitrate in a container, add 30ml of deionized water, and stir at room temperature for 5min to fully dissolve the raw materials in deionized water;

[0050] 2) Add 6.3g of analytically pure citric acid as a complexing agent, and continue stirring at room temperature until the citric acid is completely dissolved;

[0051] 3) Ammonia water with a concentration of 30 wt% was added dropwise to adjust the pH value of the solution to 7;

[0052] 4) Stir in a water bath at 80°C until a gel is formed;

[0053]5) Dry the gel in an oven at 120°C for 3 hours to obtain a xerogel;

[0054] 6) Ignite at any point of the xerogel to produce self-propagating combustion until all the xerogel is burned to obtain a f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com