Black-increasing agent for high-temperature infrared-radiation energy-saving coating and preparation method of black-increasing agent

An energy-saving coating, high-temperature infrared technology, applied in coatings, sustainable manufacturing/processing, chemical industry, etc., can solve the problems of high cost, unstable performance of infrared radiation coatings, etc., to achieve extended service life, stable radiation rate, excellent The effect of abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A blackening agent for high-temperature infrared radiation energy-saving coatings, which is prepared from the following raw materials in weight percentage:

[0029] MnO 2 : 20%, Fe 2 o 3 : 20%, CuO: 10%, Co 2 o 3 : 1%, Cr 2 o 3 : 10%,

[0030] NiO: 10%, black corundum powder: 29%.

[0031] According to needs, corundum powder can be at least one of black corundum, brown corundum and white corundum

[0032] The preparation method of above-mentioned blackening agent, its step is:

[0033] Step 1, the MnO 2 , Fe 2 o 3 , CuO, Co 2 o 3 、Cr 2 o 3 , NiO and corundum powder are mixed evenly with a mixer in proportion, and then the mixture is pressed into a block.

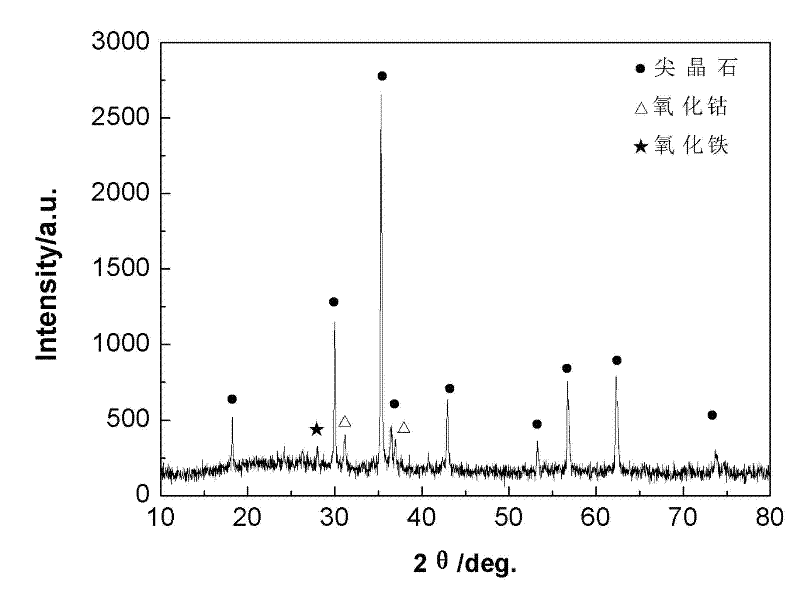

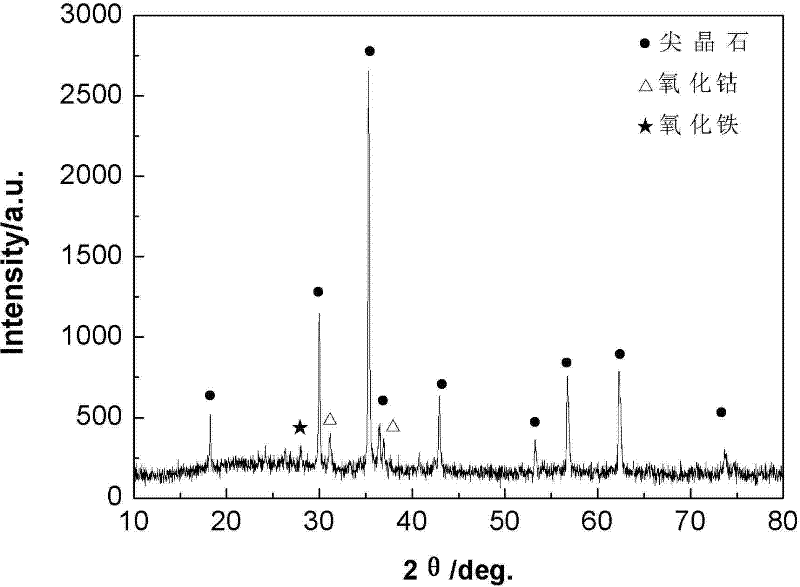

[0034] Step 2, sintering the block mixture above at high temperature, that is, sintering at 1350° C. for 3 hours, performing doping and solid solution reaction to form a blackening agent with a spinel structure.

[0035] Step 3, cooling the sintered block mixture, crushing and grinding it to a size be...

Embodiment 2

[0037] A blackening agent for high-temperature infrared radiation energy-saving coatings, which is prepared from the following raw materials in weight percentage:

[0038] MnO 2 : 42%, Fe 2 o 3 : 15%, CuO: 8%, Co 2 o 3 : 5%, NiO: 10%,

[0039] Total of brown and white corundum: 20%.

[0040] The preparation method of above-mentioned blackening agent, its step is:

[0041] Step 1, the MnO 2 , Fe 2 o 3 , CuO, Co 2 o3 、Cr 2 o 3 , NiO and corundum powder are mixed evenly with a mixer in proportion, and then the mixture is pressed into a block.

[0042] Step 2: Sinter the block mixture above at high temperature, that is, sinter at 1350° C. for 2 hours, perform doping and solid solution reaction to form a blackening agent with a spinel structure.

[0043] Step 3, cooling the sintered block mixture, crushing and grinding it to a size below 280 mesh, and obtaining a blackening agent for high-temperature infrared radiation energy-saving coatings. The blackening agent make...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

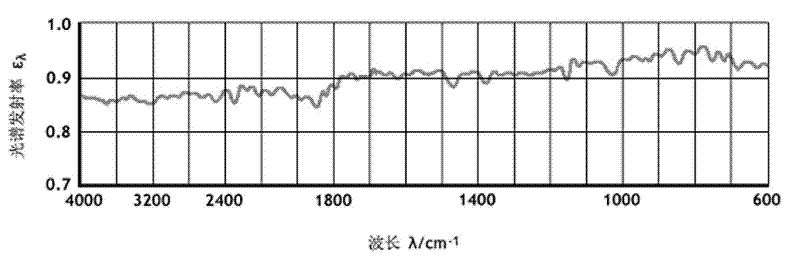

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com