Dual-purpose adhesive for steel wire rope and canvas and preparation method of dual-purpose adhesive

A technology of adhesive glue and steel wire rope, which is applied in the field of rubber, can solve the problems of rubber waste and other problems, and achieve the effect of saving installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

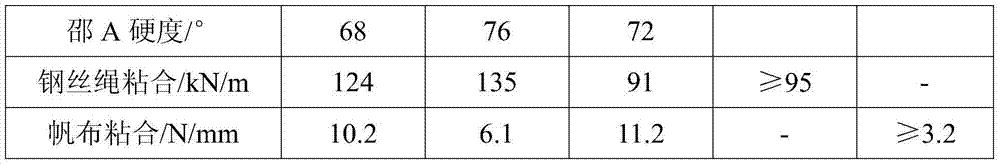

Embodiment 1

[0021] Embodiment 1: a kind of preparation method of steel wire rope and canvas dual-purpose adhesive glue comprises the following process steps, and component ratio is counted by weight parts:

[0022] (1) One-stage mixing: Add 50 parts of natural rubber (SMR10), 25 parts of styrene-butadiene rubber (SBR1502), and 25 parts of butadiene rubber in a two-roller mill, masticate for 40 seconds, and masticate at a temperature of 27°C, and then Add 3 parts of nano zinc oxide, 2 parts of stearic acid, 2 parts of anti-aging agent RD, 2 parts of anti-aging agent BLE, 1.5 parts of cobalt boroacylate, 2 parts of adhesive BN-1, 4 parts of adhesive XS-132, 30 parts of carbon black N220, 15 parts of white carbon black, 6 parts of coumarone and 4 parts of aromatic oil were mixed for 20 minutes at a mixing temperature of 55°C, and a mixed rubber was obtained after 12 hours of parking;

[0023] (2) Two-stage mixing: Add 1.8 parts of accelerator AC-P84, 0.7 parts of accelerator NS, 2 parts of s...

Embodiment 2

[0025] Embodiment 2: a kind of preparation method of steel wire rope and canvas dual-purpose adhesive glue, comprises the following processing steps, and component ratio is counted by weight parts:

[0026] (1) One-stage mixing: Add 60 parts of natural rubber (SMR10) and 40 parts of styrene-butadiene rubber (SBR1712) into a two-roller mill, masticate for 30 seconds, and masticate at a temperature of 30°C, then add 2 parts of nano-zinc oxide in sequence , 1 part of stearic acid, 2 parts of antioxidant 4020, 10 parts of cobalt caprate, 2 parts of binder RE, 30 parts of carbon black N330, 15 parts of carbon black N550, 15 parts of white carbon black and 15 parts of chlorinated paraffin, Mixing for 25 minutes, the mixing temperature is 65°C, and a section of mixed rubber is obtained after parking for 8 hours;

[0027] (2) Second-stage mixing: Add 3 parts of accelerator CZ and 2 parts of sulfur to the first-stage mixed rubber obtained in step (1), and mix for 3 minutes at a mixing ...

Embodiment 3

[0029] Embodiment 3: a kind of preparation method of dual-purpose adhesive glue for steel wire rope and canvas, comprises the following process steps, and component ratio is counted by weight parts:

[0030] (1) One-stage mixing: add 40 parts of natural rubber (SMR10), 30 parts of neoprene rubber, and 30 parts of nitrile rubber in a two-roller open mill, masticate for 60 seconds, and masticate at a temperature of 20°C, and then add 5 parts in sequence Nano zinc oxide, 3 parts of stearic acid, 2 parts of anti-aging agent 4020, 2 parts of anti-aging agent BLE, 2 parts of anti-aging agent RD, 2 parts of cobalt naphthenate, 1 part of adhesive RS, 20 parts of carbon black N115, 10 parts White carbon black and 5 parts of coumarone were mixed for 15 minutes at a temperature of 45°C, and a section of mixed rubber was obtained after being parked for 16 hours;

[0031] (2) Two-stage mixing: Add 0.2 parts of accelerator TMTD, 0.3 parts of accelerator DM, 3 parts of sulfur, 2 parts of vul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com