Non-conducting rubber applied to power cable accessories and preparation method of non-conducting rubber

A technology for insulating rubber and power cables, used in rubber insulators, organic insulators, etc., can solve the problems of poor mechanical properties such as tensile strength and tear strength, poor oil and solvent resistance, and poor physical and mechanical properties. Achieving the effect of good dimensional stability, lower production cost and high hygiene level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

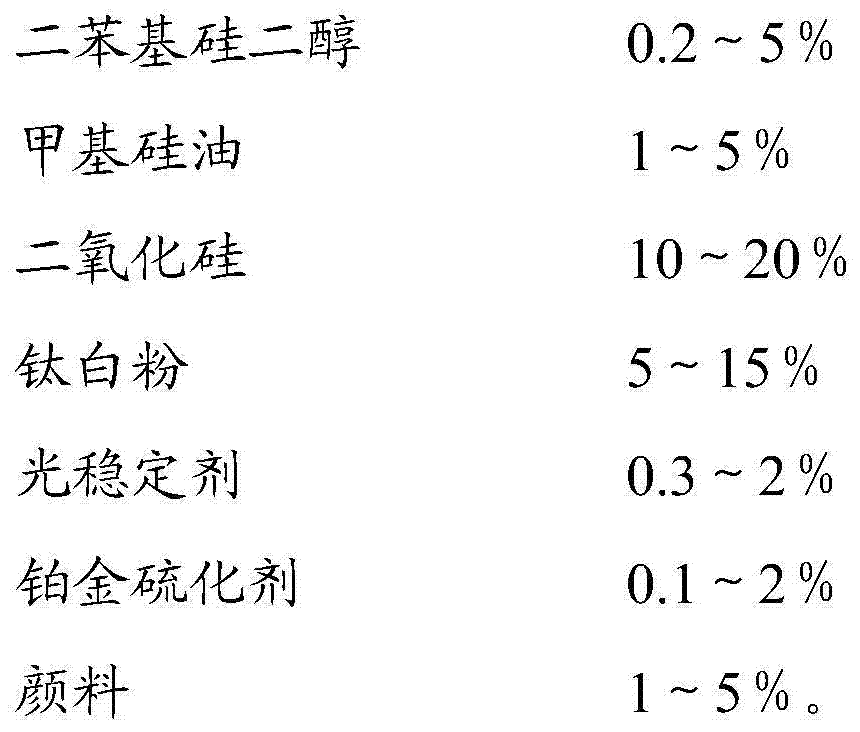

Method used

Image

Examples

Embodiment 1

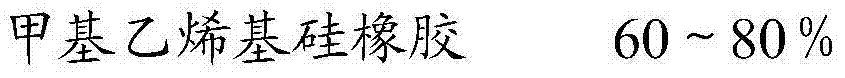

[0041] First weigh methyl vinyl silicone rubber, diphenylsilanediol, methyl silicone oil, fumed silica, titanium dioxide, and hindered amine light stabilizer in proportion;

[0042] Then put the raw materials into the kneader in order: methyl vinyl silicone rubber → diphenylsilanediol → methyl silicone oil → hindered amine light stabilizer → titanium dioxide → fumed white carbon black kneading at room temperature for 40 minutes; Take out the kneaded rubber material, put it into an open mill for mixing, and re-mill it in the form of a triangular bag for 10 minutes to form a block, and then put it into a filter for extrusion and filtration. The stainless steel mesh has three layers, and the pore size of each layer is sequential. 10mm, 50mm, 120mm, masterbatch after extrusion and filtration;

[0043] Put the masterbatch into the open mill for refining, softening, and rolling, and then add gray pigment (mixed uniformly), platinum vulcanizing agent A (mixed uniformly for 10 minutes) ...

Embodiment 2

[0045] Others are the same as in Example 1, the difference is that after the masterbatch is obtained: put 1 / 2 of the masterbatch into the open mill for refining, softening, and roll wrapping, then add → gray pigments are mixed evenly → platinum vulcanizing agent A is mixed for 10 minutes to obtain a uniform A masterbatch;

[0046] Put the other 1 / 2 of the masterbatch into the open mill to knead thoroughly, knead softly, wrap the roll, add platinum vulcanizing agent B and mix for 10 minutes to obtain the B masterbatch evenly;

[0047] A masterbatch and B masterbatch are mixed for 10 minutes evenly, and the sheets (thickness 10mm±2mm) are ready for production.

[0048] Finally, put the mixed rubber into a rubber injection machine equipped with a mold for injection molding, cross-link molding at 110°C / 5min, and take it out to be the product.

[0049] The present invention is compared with traditional silicone rubber performance:

[0050]

[0051]

[0052] It can be seen f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com