Preparation method of large-area molybdenum disulfide film

A molybdenum disulfide, large-area technology, applied in chemical instruments and methods, gaseous chemical plating, chemically reactive gases, etc., can solve the problems of difficult to achieve large-area growth, poor uniformity, etc., and achieve low cost and compactness. Excellent and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

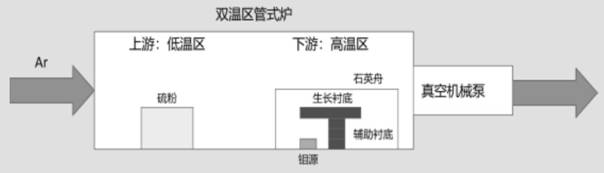

Embodiment 1

[0028] First, the substrate is ultrasonically cleaned with acetone, isopropanol, and deionized water to remove surface impurities; then, the surface is blown dry with a nitrogen gun. Place the cleaned substrate in the sputtering area of the magnetron sputtering system, and place the high-purity molybdenum target (purity>99.99%) in the sputtering target position in the magnetron sputtering machine, at 1.0×10 -3 Under the vacuum degree of Pa, a constant current source is used for sputtering, and the sputtering rate is 0.18nm / s. The obtained substrate containing the metal molybdenum source was placed in a tube furnace, exposed to air and heated for full oxidation. The oxidation temperature was 250° C., and the treatment time was 120 minutes. Put the molybdenum oxide source substrate face up into the bottom of the quartz boat, stack 4 silicon wafers next to the substrate in the downstream position of the airflow as auxiliary substrates, and place the silicon wafer with a larger ...

Embodiment 2

[0030] First, the substrate is ultrasonically cleaned with acetone, isopropanol, and deionized water to remove surface impurities; then, the surface is blown dry with a nitrogen gun. Place the cleaned substrate in the sputtering area of the magnetron sputtering system, and place the high-purity molybdenum target (purity>99.99%) in the sputtering target position in the magnetron sputtering machine, at 1.0×10 -3 Under the vacuum degree of Pa, a constant current source is used for sputtering, and the sputtering rate is 0.18nm / s. The obtained substrate containing the metal molybdenum source was placed in a tube furnace, exposed to air and heated for full oxidation. The oxidation temperature was 250° C., and the treatment time was 120 minutes. Put the molybdenum oxide source substrate face up into the bottom of the quartz boat, stack 4 silicon wafers next to the substrate in the downstream position of the airflow as auxiliary substrates, and place the silicon wafer with a larger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com