A kind of micro drill bit and processing method thereof

A micro-drill and drill-tip technology, which is applied in metal processing equipment, twist drills, drill accessories, etc., can solve the problems of affecting hole position accuracy, space reduction, and excessive heating of drill tips, so as to improve heat dissipation efficiency and heat dissipation efficiency Improve and improve the effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

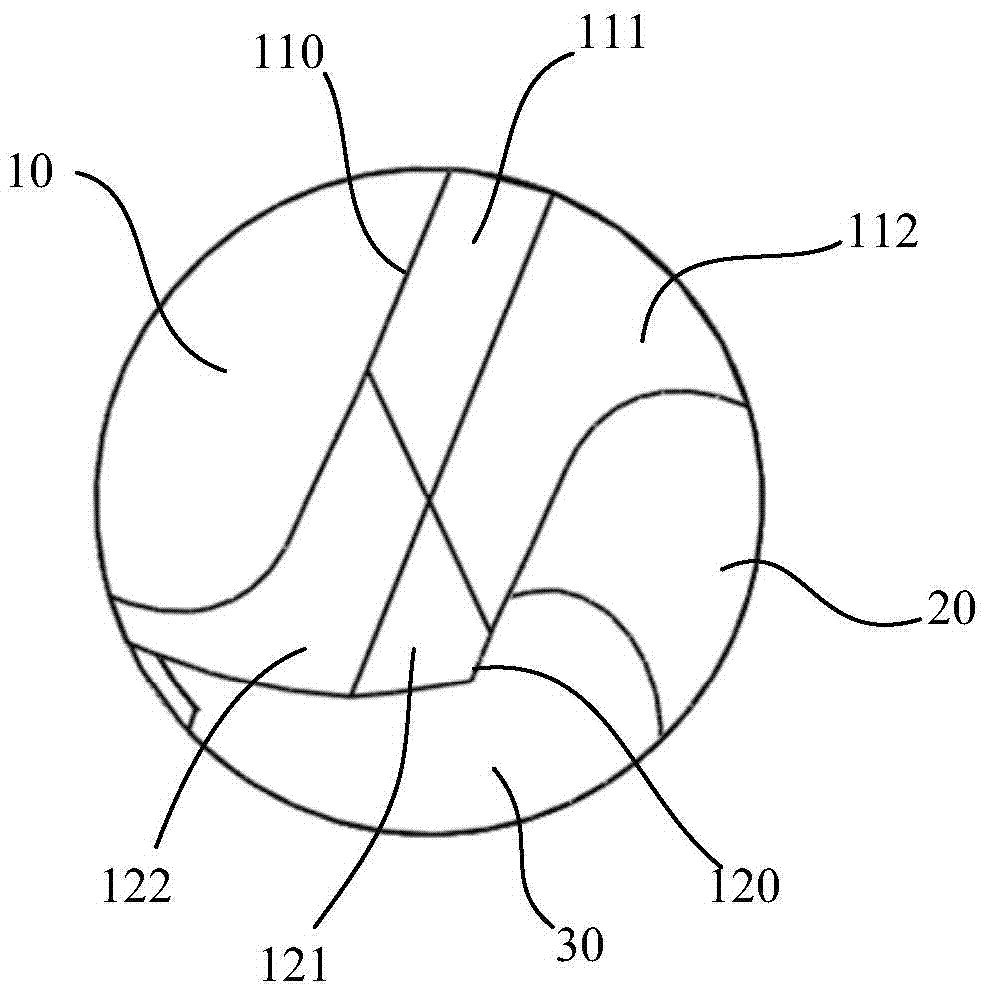

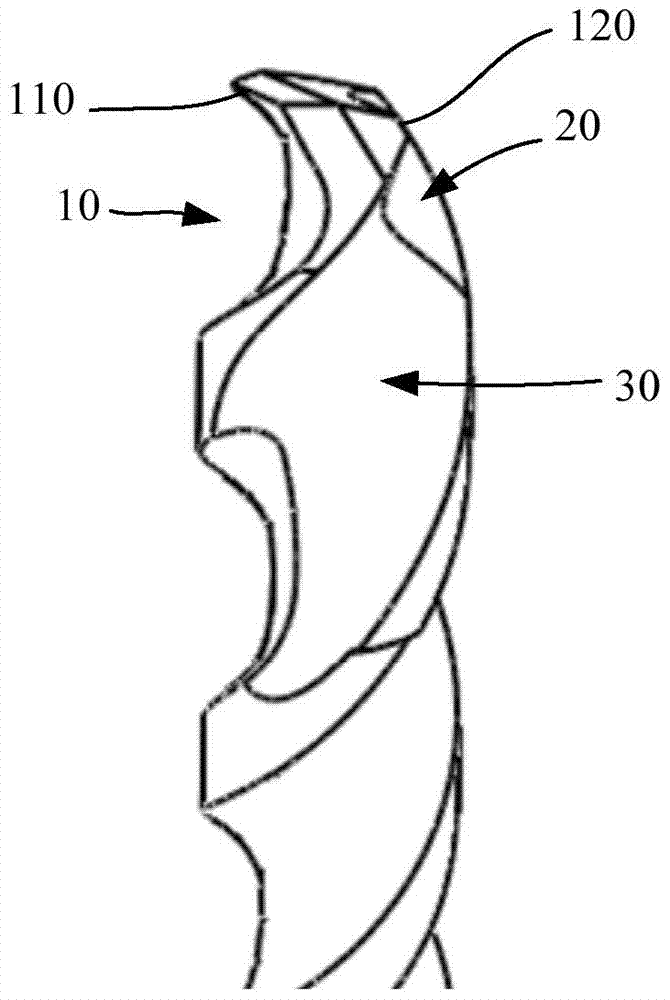

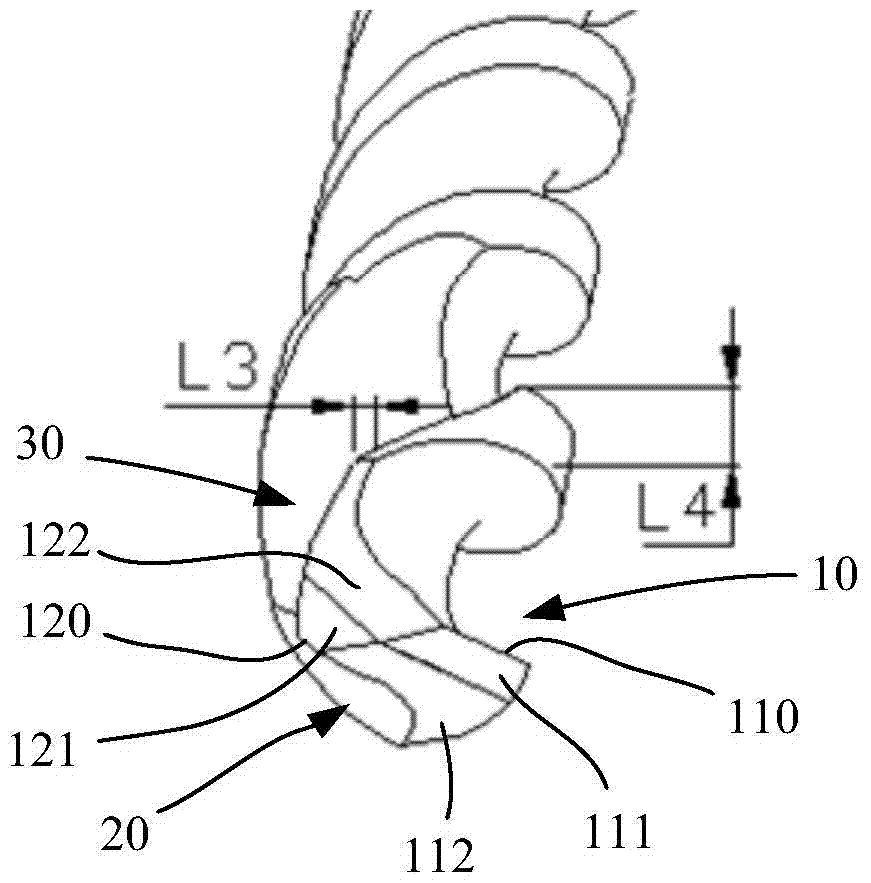

[0039] Such as Figure 1 to Figure 3 As shown, the micro drill includes: a first rake face 111, a first relief face 112, a second rake face 121, and a second flank 122 arranged at the drill point; The first helical groove 10 and the second helical groove 20 arranged symmetrically with the first helical groove, the first helical groove 10 intersects with the first rake face 111 to form a first cutting edge 110, the second The helical groove 20 intersects with the second rake face 121 to form a second cutting edge 120; and an offset groove 30 arranged at the front end region of the drill bit, as Figure 5 As shown, the offset groove 30 intersects with the second rake face 121, so that the length L1 of the second cutting edge 120 is smaller than the length L2 of the first cutting edge 110, and the offset groove 30 and the The second helical grooves 20 intersect. The depth of the offset groove 30 is greater than the depth of the second flute 20, which can expand the space of the...

Embodiment 2

[0045] Such as Figure 6 to Figure 7 As shown, the difference from the first embodiment is that the length of the intersection of the second flank 122 and the drill body in the first embodiment is less than zero; 10 intersect each other, so that the ability of the dust suction device to absorb air extends to the area of the first spiral groove 10, so that the hot air can be sucked out as soon as possible, and the heat dissipation efficiency is improved.

[0046] As a design structure of this embodiment, the helix angle of the offset groove 30 is different from the helix angle of the second helical groove. This is because different processing requirements have different requirements on drill bit strength and hole position accuracy. Therefore, the helix angle of the offset groove 30 can be selected according to requirements.

Embodiment 3

[0048] Such as Figures 8 to 9 As shown, the difference from Embodiment 2 is that in this embodiment, the first helical groove 10 and the second helical groove 20 are arranged symmetrically, and the offset groove 30 extends from the outside of the second helical groove to the second helical groove. Inside the groove 20, the intersecting area between the offset groove 30 and the second helical groove 20 is smaller than the width of the second helical groove 20, and the depth of the offset groove 30 is greater than the depth of the second helical groove 20; Accelerates the suction of air in the drill tip area to further improve heat dissipation efficiency. Moreover, the helix angle of the offset groove 30 is the same as the helix angle of the second helical groove 20. According to the strength requirements of the structure of the drill body, this structure can ensure that the thickness of the drill core in the drill tip area is relatively consistent, thereby relatively increasin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com