Coating composite separation membrane and preparation method thereof

A composite separator and coating technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve problems affecting battery consistency and safety, weak electrolyte absorption and retention, and lithium battery charging Discharge efficiency and other issues, to improve absorption and retention capacity, reduce production costs, and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

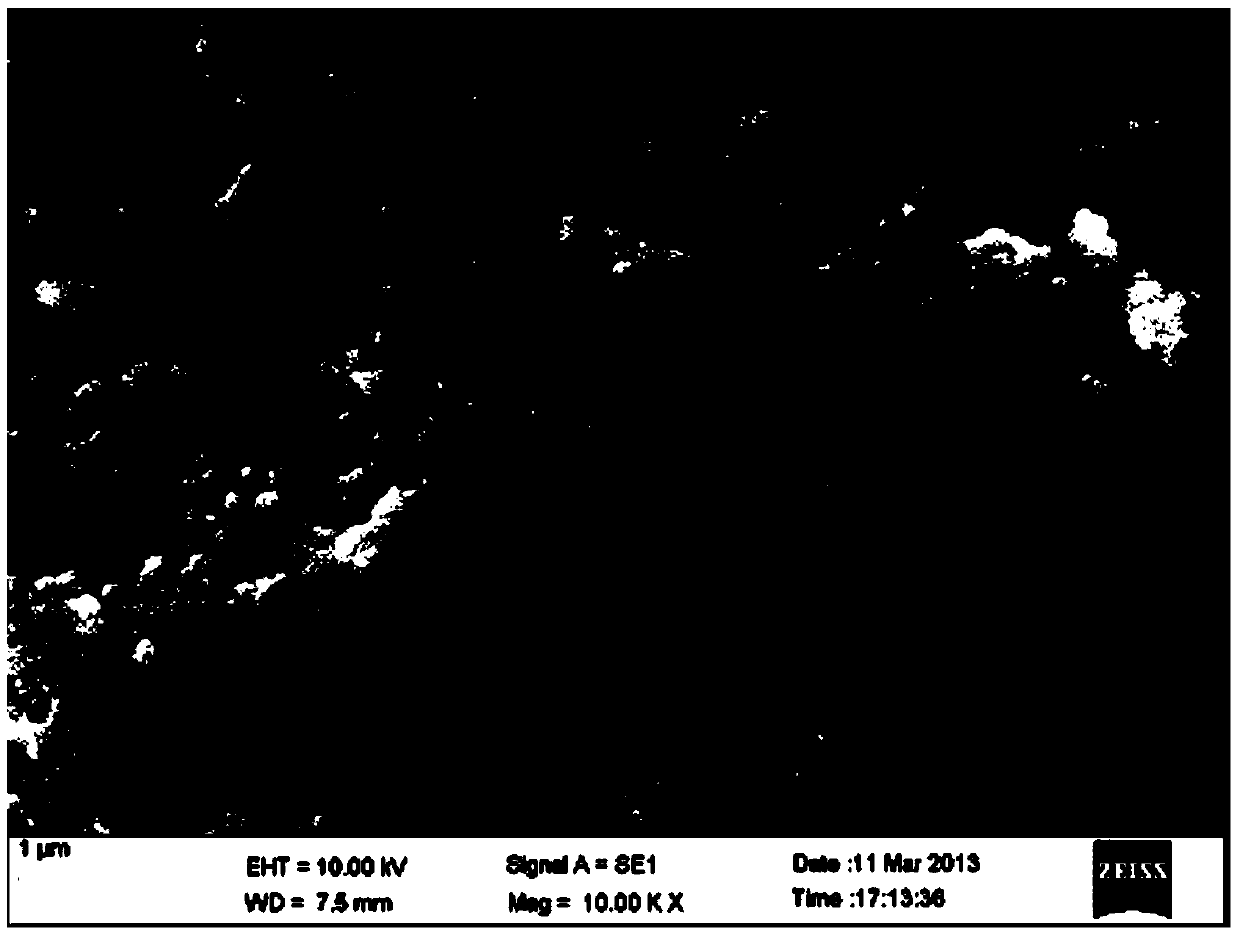

Embodiment 1

[0034] A kind of coated composite diaphragm, comprises base film and the polymer coating layer that is coated on the base film surface, and its polymer coating layer is formed by water-based slurry coating, and in the water-based slurry, the weight proportion PVDF-HFP ( polyvinylidene fluoride-hexafluoropropylene copolymer): deionized water=100:500. First, add the adhesive PVA (polyvinyl alcohol) and the tackifier CMC into deionized water, and stir at 300r / min for 20min at room temperature until they are completely dissolved. The weight ratios of PVA and CMC are PVA:PVDF-HFP= 3:100, CMC:PVDF-HFP=1:100. Then add fluorocarbon surfactant, water-based dispersant polyoxypropylene mannitol dioleate and PVDF-HFP powder in order to the above solution, continue to stir at 300r / min for 10min, and finally stir at 5000r / min for 5min at high speed, The material configuration is complete. Among them, fluorocarbon surfactant: PVDF-HFP=0.1:100, polyoxypropylene mannitol dioleate: PVDF-HFP=0...

Embodiment 2

[0036]A kind of coated composite diaphragm, comprises base film and the polymer coating layer that is coated on the base film surface, and its polymer coating layer is formed by water-based slurry coating, and the weight proportion PVDF-HFP in the water-based slurry: Deionized water = 100:400. First, add the adhesive PVA and tackifier CMC into deionized water, stir at 300r / min for 20min at room temperature until completely dissolved, wherein the weight ratio of PVA and CMC is PVA:PVDF-HFP=3:100, CMC :PVDF-HFP=1:100. Then add fluorocarbon surfactant, water-based dispersant polyoxypropylene mannitol dioleate and PVDF-HFP powder in order to the above solution, continue to stir at 300r / min for 10min, and finally stir at 5000r / min for 5min at high speed, The material configuration is complete. Among them, fluorocarbon surfactant: PVDF-HFP=0.1:100, polyoxypropylene mannitol dioleate: PVDF-HFP=0.3:100. The weight average molecular weight of PVDF-HFP is about 140,000, and the parti...

Embodiment 3

[0038] A kind of coated composite diaphragm, comprises base film and the polymer coating layer that is coated on the base film surface, and its polymer coating layer is formed by water-based slurry coating, and the weight proportion PVDF-HFP in the water-based slurry: Deionized water = 100:500. First, add the adhesive PVA and the tackifier CMC into deionized water, stir at 300r / min for 20min at room temperature until completely dissolved, wherein the weight ratio of PVA and CMC is PVA:PVDF-HFP=5:100, CMC :PVDF-HFP=1:100. Then add fluorocarbon surfactant, water-based dispersant polyoxypropylene mannitol dioleate and PVDF-HFP powder in order to the above solution, continue to stir at 300r / min for 10min, and finally stir at 5000r / min for 5min at high speed, The material configuration is complete. Among them, fluorocarbon surfactant: PVDF-HFP=0.1:100, polyoxypropylene mannitol dioleate: PVDF-HFP=0.3:100. The weight average molecular weight of PVDF-HFP is about 140,000, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com