Control method and device of internal noise of waste heat boiler

A waste heat boiler and internal noise technology, which is applied to the components of steam boilers, steam boilers, steam boiler accessories, etc., can solve the problems of high cost, inability to find waste heat boiler noise, noise reduction, etc., and achieve good low-frequency noise reduction performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1 of the present invention: a method for controlling internal noise of a waste heat boiler, comprising:

[0058] (1) The perforated sound absorbing body is used to eliminate the flow noise caused by the vortex shedding of the tube array. When eliminating the flow noise caused by the vortex shedding of the tube array, the perforated sound absorbing body is arranged at the opposite corner of the cavity between the heat exchange tube layers of the waste heat boiler on the line and perpendicular to the horizontal plane;

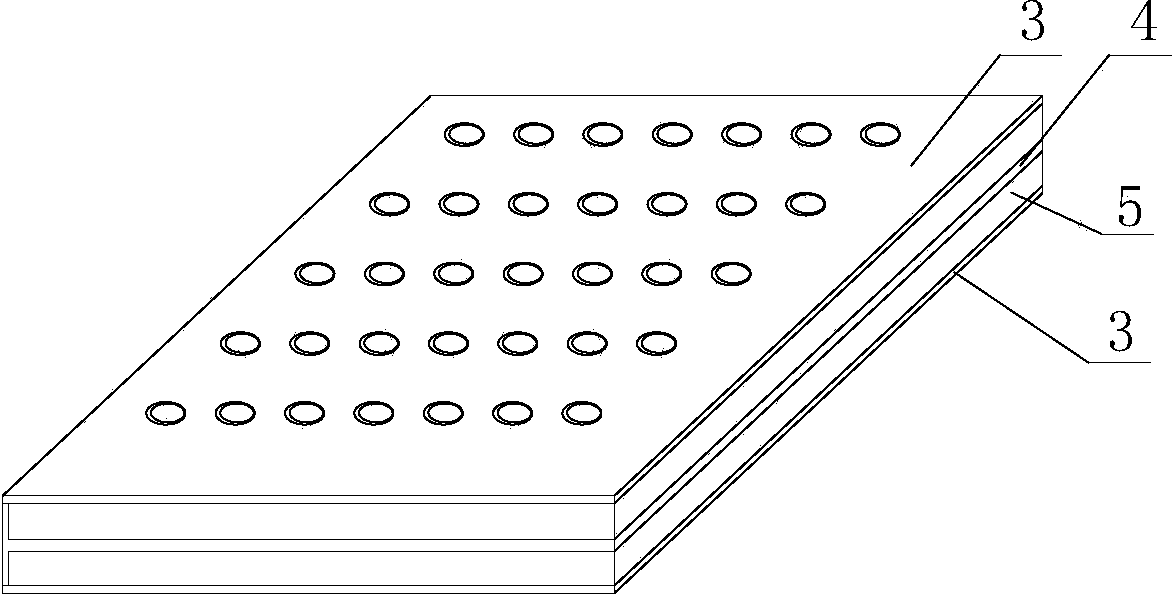

[0059] The perforated sound absorbing body 2 (such as Figure 3 ~ Figure 5 shown) includes: two perforated plates 3 and one lining plate 4, the two perforated plates 3 are attached to both sides of the lining plate 4 respectively; both sides of the lining plate 4 close to the perforated plate 3 are groove structures, so A sound-absorbing cavity 5 is formed between the perforated plate 3 and the lining plate 4, and the perforated part on the per...

experiment example 1

[0062]Experimental Example 1: The perforated sound-absorbing body used in the waste heat boiler of the present invention is composed of a perforated plate with a large number of small holes and a cavity 5 formed with the lining plate 4. It is a resonant sound-absorbing body, which can be regarded as Acoustic elements with acoustic resistance and reactance, constructed as image 3 , Figure 4 As shown, the equivalent circuit is as Figure 7 as shown, Figure 7 Among them, R and M are the sound resistance and sound quality of the perforated plate respectively, and Z D is the sound capacity of the cavity 5 behind the plate, the acoustic impedance rate of the perforated plate 3 is R+jwM, and the acoustic impedance rate of the cavity is Z S空腔 , the sound source is the incident sound wave, according to Thevenin's law, the equivalent sound source is the sound pressure and internal impedance of the open circuit (the flow is zero, that is, in front of the solid surface), that is, 2P...

experiment example 2

[0096] Experimental example 2: From the test results, it can be seen that the sound radiation of the chimney has the greatest impact on the sensitive points outside the factory, so it is considered to install a muffler at the connection between the chimney and the furnace chamber to reduce the noise from the boiler body into the chimney.

[0097] Design of resonance mufflers for waste heat boilers:

[0098] Using the principle of the Helmholtz resonator, the sound wave in the pipeline will reflect most of the sound energy back to the direction of the sound source due to the impedance mismatch near the resonance frequency, and the remaining small part of the sound energy will continue to propagate. The design objectives are mainly the resonance frequency and the amount of noise reduction, and the design parameters include the aperture d and thickness t of the perforated plate 3 0 , the perforation rate σ, the longitudinal depth of the cavity D, the flow cross-sectional area S o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com