High temperature resistant release coating material for artificial synthetic leather release paper, and preparation method and application thereof

A release coating and release paper technology, which is applied in the field of synthetic leather manufacturing, can solve the problem that solvent resistance, release stability and repeated use times are not ideal, and the release layer is difficult to meet the temperature resistance requirements, solvent resistance and high temperature resistance. Problems such as poor performance, to achieve the effect of many times of repeated use, good chemical inertness, and low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In terms of parts by mass, take 80 parts of modified polyurethane acrylate, 20 parts by mass of modified epoxy acrylate, 20 parts of tripropylene glycol diacrylate, and 20 parts of ethoxylated trimethylolpropane triacrylate , 5 parts of perfluoromethacrylate, 5 parts of γ-methacryloxypropyltrimethylsilane, put the above-mentioned components in a container at room temperature and mix and stir to promote the solid components It dissolves to obtain uniform and nearly transparent coating, which is the surface coating of release paper.

[0036] Apply the release layer to the release base paper with primer and emboss and cure it as follows:

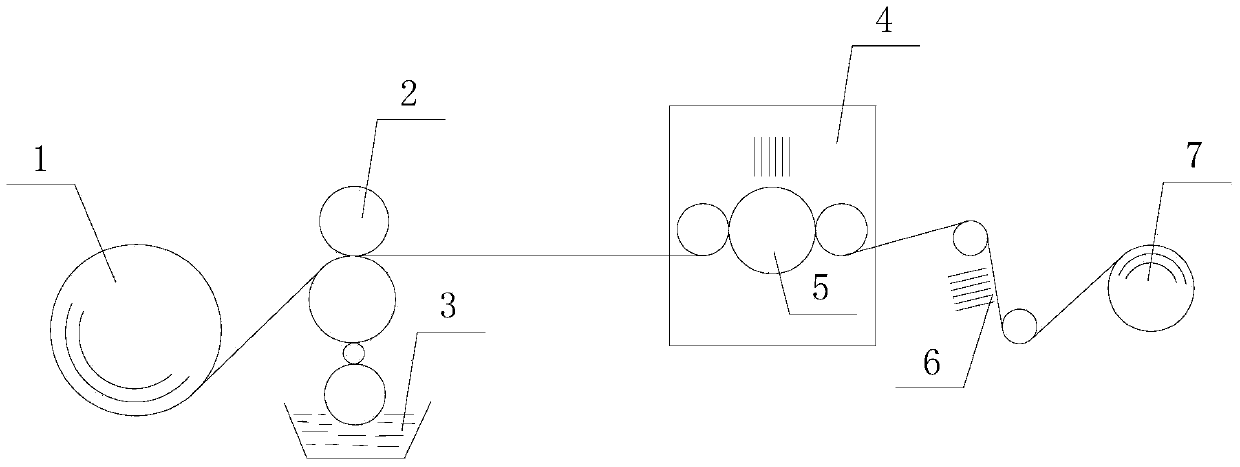

[0037] Place the release coating prepared by the above method in the feed tank 3, and the coating metering system 2 adheres to the release coating in the feed tank 3, and transfers the release coating to the paper surface of the base paper 1, and is pulled by the guide roller , The release base paper with primer is further embossed on the su...

Embodiment 2

[0039] In parts by mass, take 70 parts of modified urethane acrylate, 30 parts by mass of modified epoxy acrylate, 15 parts of tripropylene glycol diacrylate, and 15 parts of ethoxylated trimethylolpropane triacrylate , 4 parts of perfluoromethacrylate, 4 parts of γ-methacryloxypropyltrimethylsilane, according to the method of Example 1 to prepare the corresponding release paper.

Embodiment 3

[0041] In parts by mass, take 60 parts of modified polyurethane acrylate, 40 parts by mass of modified epoxy acrylate, 15 parts of tripropylene glycol diacrylate, and 15 parts of ethoxylated trimethylolpropane triacrylate , 3.5 parts of perfluoromethacrylate, 3.5 parts of γ-methacryloxypropyltrimethylsilane, according to the method of Example 1 to prepare the corresponding release paper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com