Method for processing crude ammonium tungstate solution

An ammonium tungstate and copper sulfate solution technology, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve the problems of small tungsten loss, high product purity, and no explanation of filtration treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

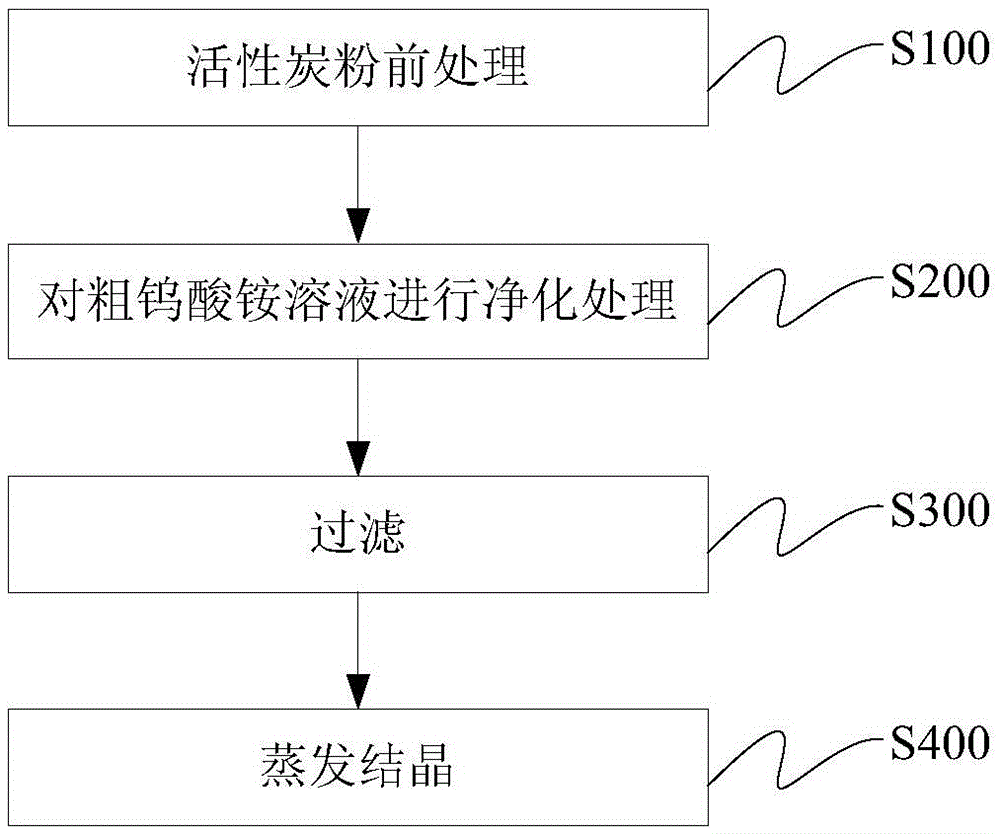

[0021] For this reason, according to one aspect of the present invention, the present invention proposes a kind of method of processing crude ammonium tungstate solution. According to a specific embodiment of the present invention, the method may specifically include:

[0022] (1) Wash the activated carbon powder with dilute hydrochloric acid;

[0023] (2) Add copper sulfate solution, ammonium sulfide solution and washed activated carbon powder to the crude ammonium tungstate solution to purify the crude ammonium tungstate solution;

[0024] (3) Filter the purified ammonium tungstate solution to obtain filter residue containing activated carbon powder and pure ammonium tungstate solution; and

[0025] (4) Evaporate and crystallize the pure ammonium tungstate solution to obtain ammonium paratungstate.

[0026] The method for processing the thick ammonium tungstate solution according to the embodiments of the present invention is by adding activated carbon powder in the thick ...

Embodiment 1

[0049] The activated carbon powder was washed with dilute hydrochloric acid, and the physical properties of the washed activated carbon powder are shown in Table 1.

[0050] Table 1

[0051] Activated carbon powder particle size

Subblue decolorization (ml / 0.1)

Iodine adsorption value (mg / g)

PH value

325 mesh (46 micron)

13

1104

10.5

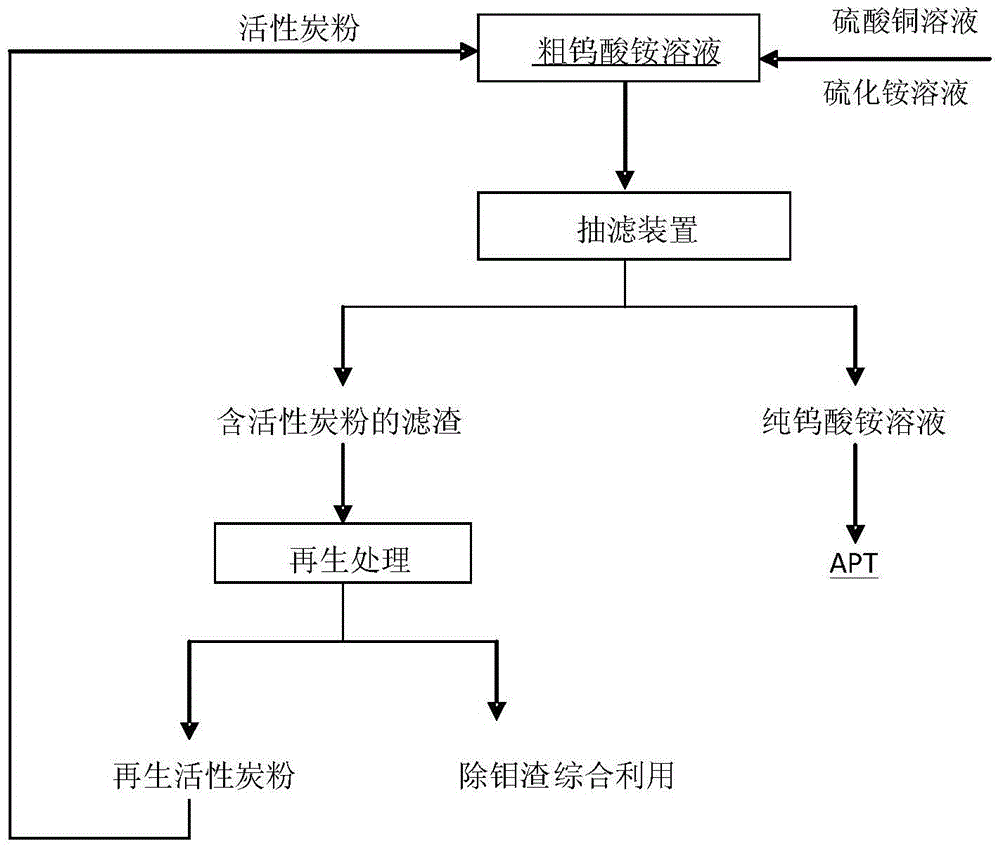

[0052] refer to figure 2 , add ammonium sulfide solution (in S 2+ Calculated, the concentration is 80g / l) 0.98ml, copper sulfate solution (200g / l) 0.12ml and washed activated carbon powder 8g, stirred for 20 minutes, and filtered with a suction filtration device. The filtrate was evaporated and crystallized, and the pH at the end point was 6.7. The test results are shown in Table 2.

[0053] Table 2

[0054] K

Na

P

S

Al

As

Bi

Ca

Cd

co

Cr

Cu

4

3

<5

<5

<4

<8

<1

<5

<1

<4

<4

1

Fe

Mg

mn

M...

Embodiment 2

[0058] The activated carbon powder was washed with dilute hydrochloric acid, and the physical properties of the washed activated carbon powder are shown in Table 1.

[0059] refer to figure 2 , add ammonium sulfide solution (in S 2+ Calculated, the concentration is 80g / l) 0.98ml, copper sulfate solution (200g / l) 0.12ml and washed activated carbon powder 15g, stirred for 20 minutes, and filtered with a suction filtration device. The filtrate was evaporated and crystallized, and the pH at the end point was 6.7. The test results are shown in Table 3.

[0060] table 3

[0061] K

Na

P

S

Al

As

Bi

Ca

Cd

co

Cr

Cu

8

6

<5

<5

<4

<8

<1

<5

<1

<4

<4

1

Fe

Mg

mn

Mo

Ni

Pb

Sb

Si

sn

Ti

V

<5

<3

<5

5

<3

<1

<5

<5

<1

<4

<4

[0062] The filter residue containing activated carbon powder is washed to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com