CeO2-MoO3/graphene low-temperature denitration catalyst and preparation method

A low-temperature denitration and graphene technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as affecting the life of catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

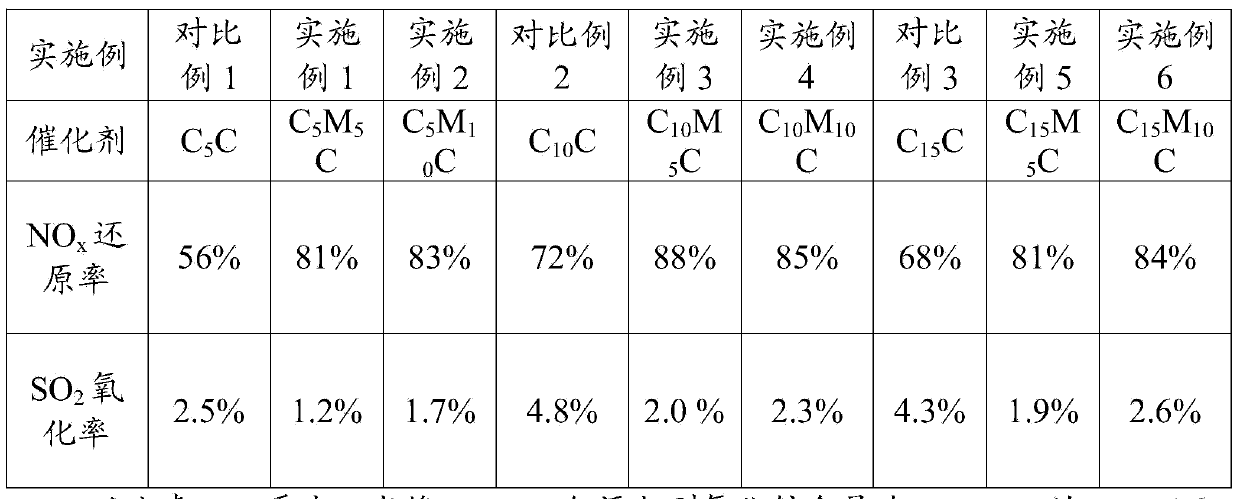

Examples

Embodiment 1

[0035] Embodiment 1 a kind of CeO 2 -MoO 3 / Graphene low-temperature denitrification catalyst (C 5 m 5 C) Preparation:

[0036] Include the following steps:

[0037] (1) Wash a certain amount of graphene with deionized water, and then dry it in an oven at 105°C for use;

[0038](2) Pour the graphene prepared in (1) into deionized water 5 times the mass of the graphene, place it in a 60°C environment and stir for 2 hours to obtain a mixture A;

[0039] (3) taking a cerium nitrate solution with a cerium element content of 5 parts by weight and introducing it into the mixture A, and stirring it in an environment of 60° C. for 5 hours to obtain a mixture B;

[0040] (4) Weigh 5 parts by weight of molybdenum trioxide and dissolve it in ammonia water 3 times the mass of molybdenum trioxide to obtain solution B;

[0041] (5) Import the solution B obtained in step (4) into the mixture B with a graphene content of 90 parts by weight, then add concentrated nitric acid to adjust th...

Embodiment 2

[0043] Embodiment 2 a kind of CeO 2 -MoO 3 / Graphene low-temperature denitrification catalyst (C 5 m 10 C) Preparation

[0044] Include the following steps:

[0045] Steps (1) to (3) are the same as in Example 1;

[0046] (4) Weigh 10 parts by weight of molybdenum trioxide and dissolve it in ammonia water 3 times the mass of molybdenum trioxide to obtain solution B;

[0047] (5) Import the solution B obtained in step (4) into the mixture B with a graphene content of 85 parts by weight, then add concentrated nitric acid to adjust the pH value to 1, shake at 60°C for 5h, and then heat up to 80°C and drying at 80°C for 48 hours to obtain mixture C;

[0048] (6) Put the mixture C obtained in step (5) in a muffle furnace, and raise the temperature to 350°C at 10°C / min. 2 Calcined for 6 hours under the protection of the atmosphere, and ground into 50-200 meshes to obtain the catalyst C 5 m 10 C, which includes cerium oxide with a mass percentage of 5%, molybdenum trioxide w...

Embodiment 3

[0049] Embodiment 3 a kind of CeO 2 -MoO 3 / Graphene low-temperature denitrification catalyst (C 10 m 5 C) Preparation

[0050] Follow these steps:

[0051] Steps (1) to (2) are the same as in Example 1;

[0052] (3) taking a cerium nitrate solution with a cerium element content of 10 parts by weight and introducing it into the mixture A, placing it in an environment of 60° C. and stirring for 5 hours to obtain a mixture B;

[0053] (4) Weigh 5 parts by weight of molybdenum trioxide and dissolve it in ammonia water 3 times the mass of molybdenum trioxide to obtain solution B;

[0054] (5) Import the solution B obtained in step (4) into the mixture B with a graphene content of 85 parts by weight, then add concentrated nitric acid to adjust the pH value to 1, shake at 60°C for 5h, and then heat up to 80°C and drying at 80°C for 48 hours to obtain mixture C;

[0055] (6) Put the mixture C obtained in step (5) in a muffle furnace, and raise the temperature to 350°C at 10°C / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com