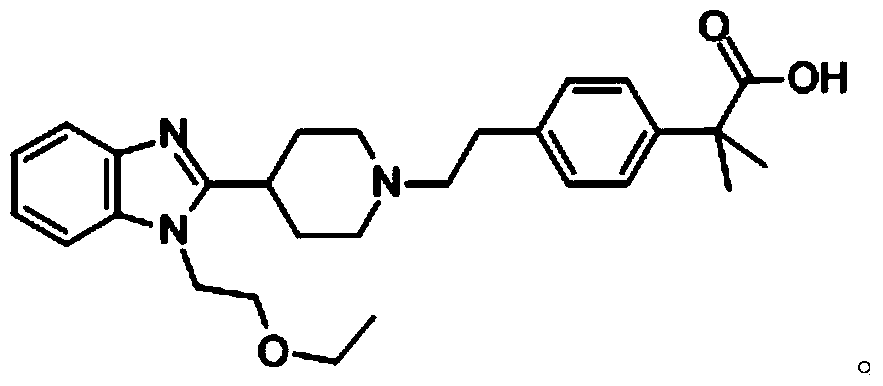

Bilastine sustained-release capsule

A technology of sustained-release capsules and bilastine, which is applied in the directions of drug delivery, respiratory diseases, organic active ingredients, etc., can solve the problems of ineffective control of the release amount, poor safety and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation process of the above-mentioned bilastine sustained-release capsules adopts the following several processes to prepare:

[0019] (1) Extrusion spheronization method: use an extrusion spheronizer to mix the raw material medicine and excipients through an 80-mesh screen, spray the mixed powder with a binder in the extrusion spheronizer, and then extrude and spheronize Make pellets, dry and sieve to obtain drug-containing pellets with a certain mesh size. Coating with ethyl cellulose aqueous dispersion in a fluidized bed coating pan;

[0020] (2) Powder coating method: use a non-porous coating pan, a water chestnut-shaped coating pan, a fluidized bed top spray (or bottom spray) coating machine, and a fluidized bed tangential spray to make pellets. Take the water chestnut-shaped coating pot as an example: mix the medicinal powder and excipients through an 80-mesh sieve, take a certain number of pellets (sucrose pills or microcrystalline cellulose pills) into...

Embodiment 1

[0024] A bilastine sustained-release capsule is composed of 5% bilastine, 90% excipient, 3% film coating material, 1% wetting agent and 1% binder. Wherein the excipient is microcrystalline cellulose, the film coating material is ethyl cellulose aqueous dispersion, the wetting agent is 75% ethanol solution, and the binder is aqueous solution of hydroxypropyl methyl cellulose. A kind of preparation technology of bilastine sustained-release capsule, it adopts following technology to prepare:

[0025] Utilize extruding spheronization method: utilize extruding spheronizing granulator, crude drug and microcrystalline cellulose are mixed and crossed 80 mesh screens, mix powder with the aqueous solution of hydroxypropyl methylcellulose in extruding spheronizing granulator After spraying wet, extrude and spheronize to form pellets, and after drying, sieve to obtain drug-containing pellets with a certain mesh size, which are coated with ethyl cellulose aqueous dispersion in a fluidized ...

Embodiment 2

[0027] A bilastine sustained-release capsule, wherein the sustained-release capsule is made up of 8% bilastine, 75% excipient, 10% film coating material, 5% wetting agent and 2% binding agent . Wherein the excipient is starch, the film coating material is ethyl cellulose aqueous dispersion, the wetting agent is aqueous solution, and the binding agent is alcohol solution of polyvinylpyrrolidone.

[0028] A kind of preparation technology of bilastine sustained-release capsule, it adopts following technology to prepare:

[0029] Powder coating method: use a non-porous coating pan, a water chestnut-shaped coating pan, a fluidized bed top spray (or bottom spray) coating machine, and a fluidized bed tangential spray pellet machine to make pellets. Take the water chestnut-shaped coating pot as an example: mix the medicine powder and starch through an 80-mesh sieve, take 30-35 mesh pellets (sucrose pills or microcrystalline cellulose pills) into the water chestnut-shaped coating pot,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com