Artificial heart valve annuloplastic ring

An artificial heart valve and forming ring technology, applied in the field of medical devices, can solve the problems of increasing defect rate, complicated manufacturing process, easy to break and crack, etc., and achieve the effects of simple and convenient processing method, easy adjustment of rigidity and high yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

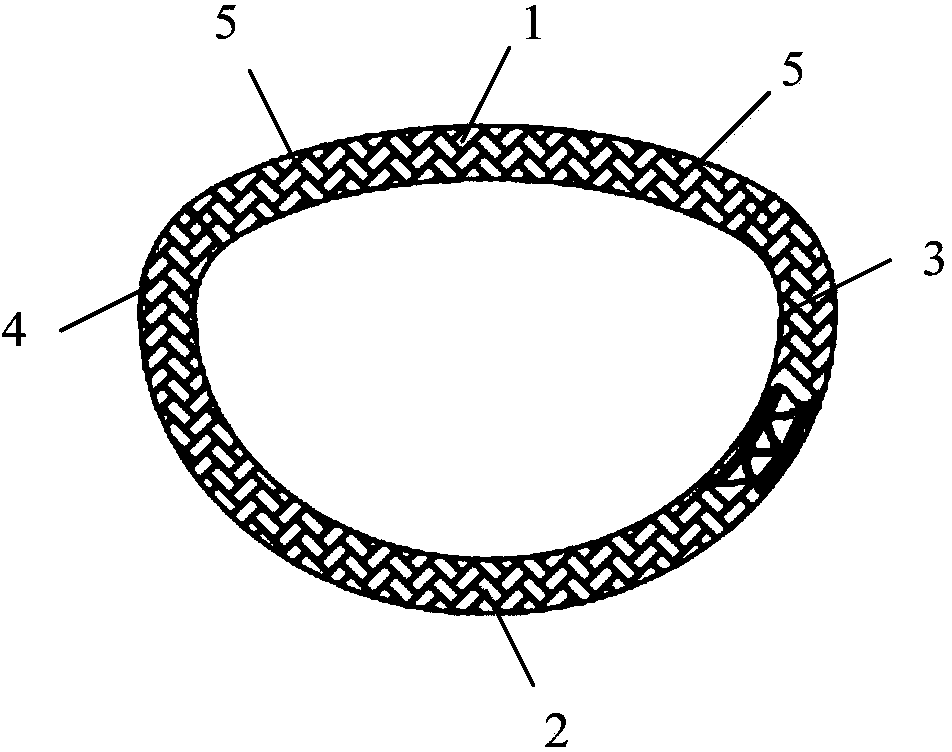

[0063] This embodiment provides an artificial mitral annulus forming ring. Such as figure 1 As shown, the mitral annuloplasty ring is a closed three-dimensional saddle-shaped structure, and its ring-shaped main body is composed of an anterior ring segment 1 , a rear ring segment 2 , a left ring segment 3 and a right ring segment 4 . The higher bow-shaped protrusion of the forming ring is the front ring segment 1, the lower protrusion is the rear ring segment 2, and the two concave segments are respectively the left ring segment 3 and the right ring segment 4, the front ring segment 1 and the left ring segment 3 Connecting segments 5 are arranged between adjacent ring segments in the right ring segment 4 and right ring segment 4 respectively.

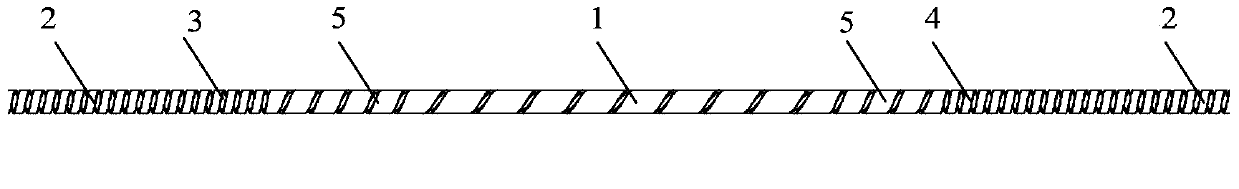

[0064] Such as figure 2 As shown, the middle point of the rear ring segment 2 is used as the connection point, and the forming ring is developed into a straight tubular helical structure along the circumferential direction, the outer ...

Embodiment 2

[0071] This embodiment provides an artificial mitral annuloplasty ring, Figure 5 In order to expand the annular body of the forming ring into a straight tubular helical structure along the circumferential direction. Figure 6 to form Figure 5 Sheet strips in a tubular helical structure. Wherein the sheet material strip in this embodiment is processed by medical stainless steel plate, its width is larger than the sheet material strip in embodiment 1, and there are a plurality of elongated hollow structures on it. Besides, other shapes and structures of the artificial mitral annulus forming ring provided in this embodiment are the same as those of the artificial mitral annulus forming ring in Embodiment 1. The present invention achieves the purpose of further adjusting the rigidity of each ring segment through the setting of the hollow structure.

Embodiment 3

[0073] This embodiment provides an artificial mitral annuloplasty ring whose shape is as figure 1 As shown, it is the same shape as the artificial mitral annuloplasty ring in Example 1.

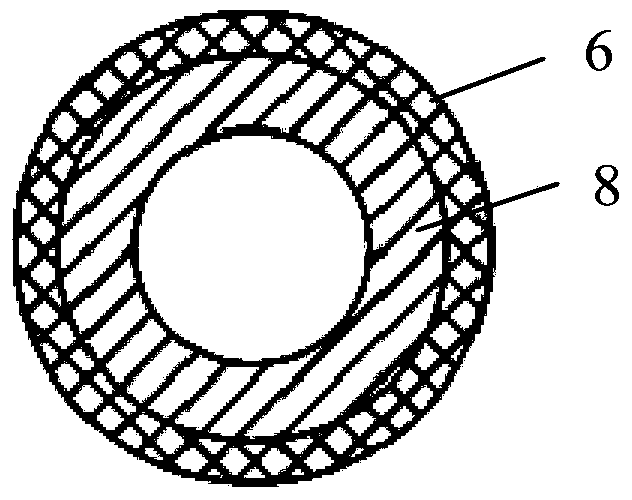

[0074] Such as Figure 7 As shown, the middle point of the rear ring segment 2 is the closed connection point, and the forming ring main body 8 is expanded into a straight tubular helical structure along the circumferential direction of the ring, and its outer diameter can be 1-3mm, and the pitch is consistent. The width of the plate strip forming the helical shape varies from place to place, and its thickness can generally be 0.1-0.6 mm, and it is formed by laser cutting or stamping and other methods. Figure 10 In order to roll the plate strips of the main structure, the main structure adopts the double plate strip method shown in the figure, and is rolled into a double helix structure, so as to increase the ability of the plate strips to resist fatigue. Such as Figure 10 As shown, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com