Vinyl alcohol polymer, and aqueous solution, coating agent, inkjet recording material, heat-sensitive recording material, and release paper base paper containing same

A technology of inkjet recording materials and heat-sensitive recording materials, applied in the direction of pigment-containing coatings, coatings, paper coatings, etc., can solve problems such as insoluble and insufficient solutions to poor conditions, and achieve high viscosity stability and high filling seams and water resistance, film strength and high water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0096]

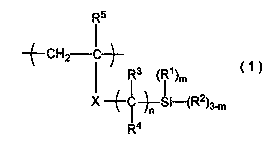

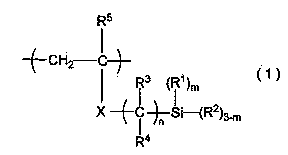

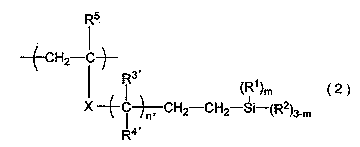

[0097] The preparation method of the PVA is not particularly limited, for example, by copolymerizing a vinyl ester monomer with a monomer endowed with a unit represented by the above formula (1), and then saponifying the resulting copolymer (vinyl ester polymer) And get.

[0098] Examples of the vinyl ester monomers include vinyl formate, vinyl acetate, vinyl propionate, vinyl valerate, vinyl caprate, vinyl laurate, vinyl stearate, and vinyl benzoate. ester, trimethyl vinyl acetate, vinyl tertiary carboxylate, etc., among them, vinyl acetate is preferred.

[0099] In addition, when the monomer imparting the unit represented by the above formula (1) is copolymerized with the vinyl ester monomer, in order to adjust the viscosity-average degree of polymerization (P) of the obtained PVA, etc., within the range that does not impair the gist of the present invention Within, the polymerization can be carried out in the presence of a chain transfer agent. Examples of the ...

Embodiment 1-1

[0272] [Example 1-1] Preparation of PVA1-1

[0273] In a 6L detachable flask equipped with a stirrer, a reflux condenser, a nitrogen introduction pipe, a comonomer dropping port, and an initiator addition port, 1,500 g of vinyl acetate, 500 g of methyl alcohol, and 1.87 g of a compound having the above formula ( 1) For MAmPTMS of the monomer (monomer A) of the group indicated, the system was replaced with nitrogen for 30 minutes while blowing nitrogen gas. In addition, MAmPTMS was dissolved in methanol as a retentate solution (Dierre's solution), and a comonomer solution having a concentration of 8% was prepared, and nitrogen replacement was performed by blowing nitrogen gas. The temperature rise of the reactor was started, and when the internal temperature reached 60°C, 0.8 g of 2,2'-azobisisobutyronitrile (AIBN) was added to start polymerization. The retained solution was added dropwise so that the monomer composition (ratio of vinyl acetate to monomer A (MAmPTMS)) in the p...

Embodiment 1-2~1-31 and comparative example 1-1~1-22

[0277] [Examples 1-2 to 1-31 and Comparative Examples 1-1 to 1-22] Preparation of PVA1-2 to PVA1-53

[0278] In addition to changing the feed amount of vinyl acetate and methanol, the type or amount of addition of monomer A and other polymerization conditions, the concentration of PVAc during saponification, the molar ratio of sodium hydroxide to vinyl acetate units, etc., as shown in Table 1 and Table 2 Except for the saponification conditions, the same operation as in Example 1-1 was performed to obtain PVA1-2 to PVA1-53. See Tables 1 and 2 for the analysis results of each of the obtained PVAs.

[0279] [Table 1]

[0280]

[0281] [Table 2]

[0282]

PUM

| Property | Measurement | Unit |

|---|---|---|

| saponification | aaaaa | aaaaa |

| saponification | aaaaa | aaaaa |

| process yield | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com