Halogen-free epoxy resin composition and application thereof

A halogen-free epoxy resin and composition technology, applied in the field of halogen-free epoxy resin composition, can solve problems such as inability to meet halogen-free requirements, poor appearance of prepregs, wear of drill tips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The technical solutions of the present invention will be further described below through specific embodiments.

[0084] The examples and comparative examples of the present invention are described in detail as follows, but the present invention is not limited to the scope of the examples. There is no special description below, and its numerical value represents parts by weight, and its "%" represents "% by weight".

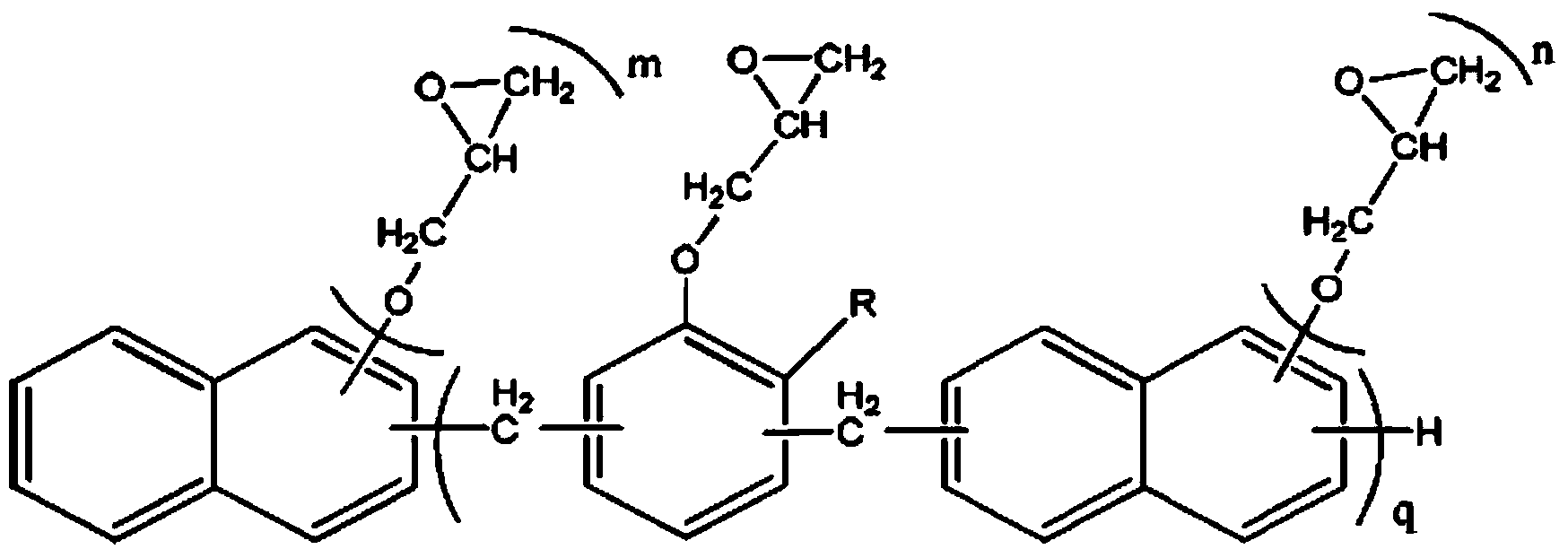

[0085] A: Epoxy resin

[0086] A1: NC-7700L, naphthol type novolac epoxy resin (Nippon Kayaku);

[0087] A2: EPR627MEK80, bisphenol A multifunctional epoxy resin (Momentive Chemical);

[0088] A3: NPEP-204, DOPO modified o-cresol novolac epoxy resin (Nanya, Taiwan);

[0089] B: first curing agent

[0090] SMA EF-40, styrene and maleic anhydride copolymer (US sartomer);

[0091] C: second curing agent

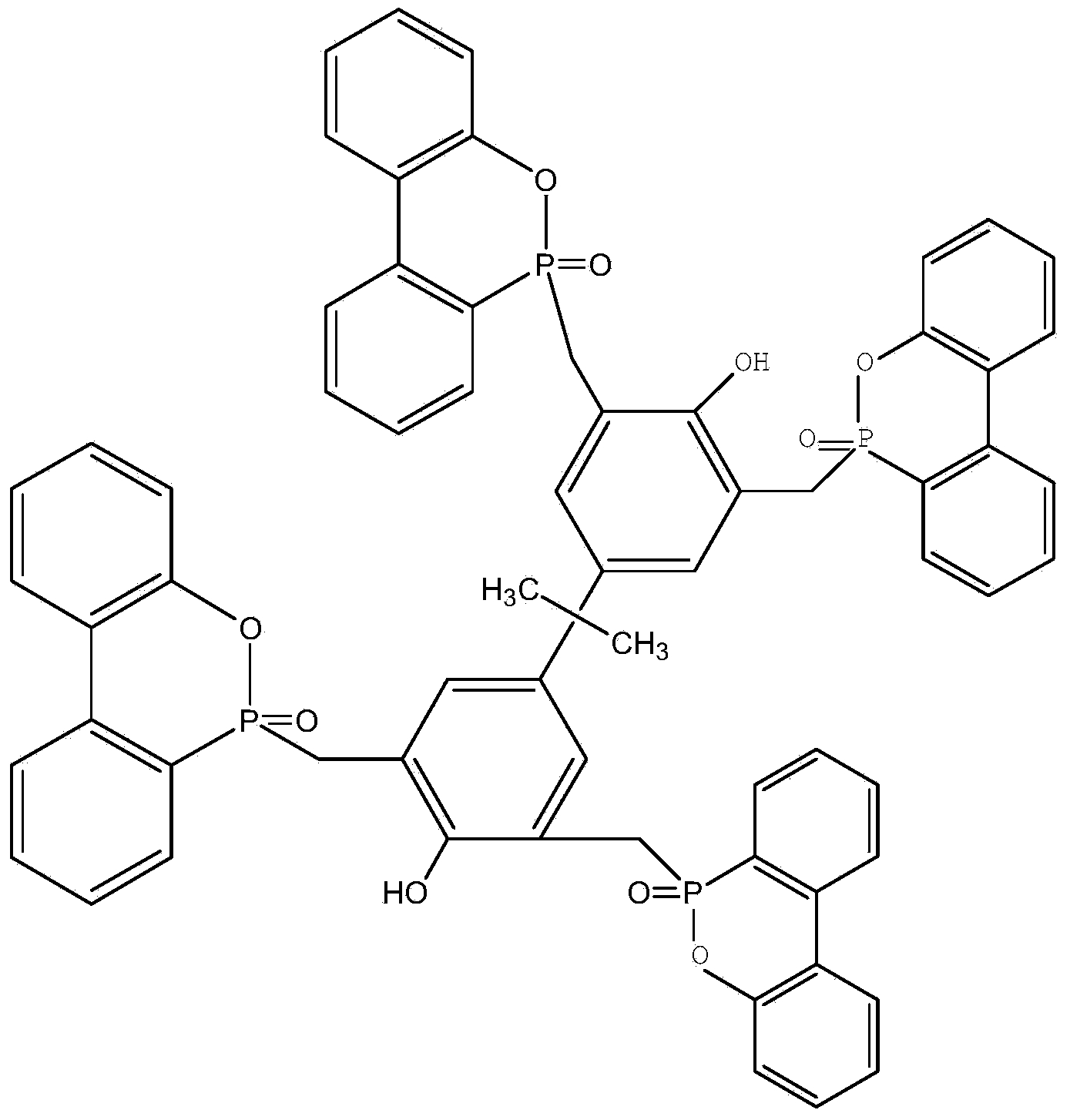

[0092] C1: XZ-92741, phosphorus-containing compound (DOW Chemical, USA), DOPO replaces phosphorus-containing phenolic formaldehyde;

[0093] C2: D125,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com