High-impact-resistant PVC rigid tube and preparation method thereof

A high-impact, rigid pipe technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of incomplete combination of additives and PVC resin, complicated transportation and installation processes, and inability to meet the requirements of use. The effect of passing rate, saving raw materials and high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

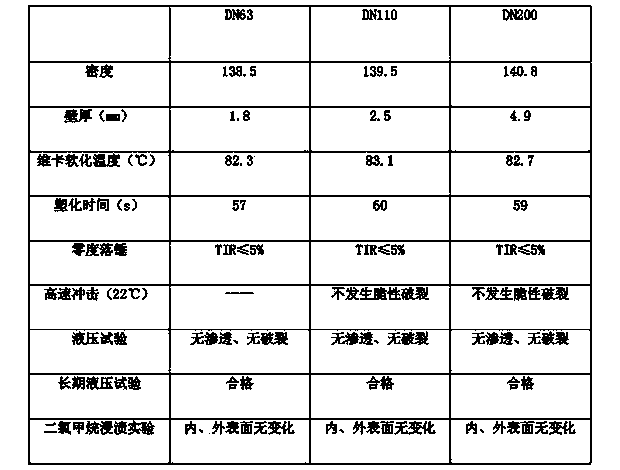

Examples

Embodiment 1

[0023] a. The proportion of raw materials by mass:

[0024] Ingredients Servings

[0025] High Impact PVC Composite Resin 100

[0026] Lubricant:

[0027] PE wax 2

[0030] stabilizer:

[0031] Organotin T-178 4

[0032] filler:

[0033] Titanium dioxide 5

[0035] b. Add the proportioned raw materials in step a into the high mixer, heat up to 100°C, and mix for 10 minutes;

[0036] c. Put it into a cold mixing pot, cool to 40°C, release it, and let it mature for 24 hours;

[0037] d. Join the twin-screw pipe extruder, the processing temperature is 170°C, according to the CJ / T272-2008 standard, select the wall thickness of the pipe to be extruded, and carry out pipe extrusion.

Embodiment 2

[0039] a. The proportion of raw materials by mass:

[0040] Ingredients Servings

[0041] High Impact PVC Composite Resin 100

[0042] Lubricant:

[0043] PE wax 1

[0045] Barium Stearate 1

[0046] stabilizer:

[0047] Organotin T-178 1

[0048] filler:

[0049] Titanium dioxide 5

[0051] b. Add the proportioned raw materials in step a into the high mixer, raise the temperature to 110°C, and mix for 8 minutes;

[0052] c. Put it into the cold mixing pot, cool to 35°C and let it out, let it mature for 24 hours;

[0053] d. Join the twin-screw pipe extruder, the processing temperature is 165°C, according to the CJ / T272-2008 standard, select the wall thickness of the pipe to be extruded, and carry out pipe extrusion.

Embodiment 3

[0055] a. The proportion of raw materials by mass:

[0056] Ingredients Servings

[0057] High Impact PVC Composite Resin 100

[0058] Lubricant:

[0059] PE wax 1

[0062] stabilizer:

[0063] Organotin T-178 6

[0064] Filler: 0

[0065] b. Add the proportioned raw materials in step a into the high mixer, raise the temperature to 105°C, and mix for 8 minutes;

[0066] c. Put it into a cold mixing pot, cool to 40°C, release it, and let it mature for 24 hours;

[0067]d. Join the twin-screw pipe extruder, the processing temperature is 175°C, according to the CJ / T272-2008 standard, select the wall thickness of the pipe to be extruded, and carry out pipe extrusion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com