Preparation method of collagen-based composite hemostatic powder

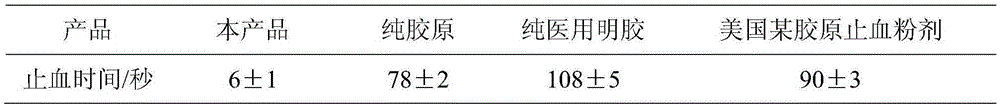

The technology of hemostatic powder and hemostatic powder is applied in the field of preparation of collagen-based composite hemostatic powder, which can solve the problems of inability to meet market requirements, troublesome surgical operation, general hemostatic performance, etc., and achieve shortened hemostasis time, excellent hemostasis performance, and good biological properties. Compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1. Preparation of Panax notoginseng raw material

[0051] At an ultrasonic frequency of 20kHz and a power of 50w, soak the notoginseng powder in 10 times the ethanol solution with a concentration of 75wt% for 15 hours, then repeatedly immerse it in 5 times the ethanol solution with a concentration of 75wt% for 5 hours, and let it stand for 0.5 hours to separate. Combine the two extracts and keep them for other use; dry the residue, add 10 times of water to soak for 15 hours; then repeat soaking with 5 times of water for 6 hours, centrifuge to obtain the filtrate, pass the filtrate directly through the Sephadex column and 0001×7 ion exchange resin was used for filtration chromatography at a flow rate of 0.5ml / min, the filtrates were combined, decolorized with 3% activated carbon, the filtrate was concentrated under reduced pressure, and spray-dried to obtain notoginseng powder.

[0052] 2. Preparation of collagen-based composite hemostatic powder

[0053] (1) Preparatio...

Embodiment 2

[0062] 1. Preparation of Panax notoginseng raw material

[0063] At an ultrasonic frequency of 30kHz and a power of 90w, soak the notoginseng powder in 20 times the ethanol solution with a concentration of 95wt% for 20 hours, then repeatedly immerse it in 10 times the ethanol solution with a concentration of 95wt% for 10 hours, and let it stand for 1.0 hours to separate. Combine the two extracts and keep them for other use; dry the residue, add 15 times of water to soak for 20 hours; then use 10 times of water to repeatedly soak for 10 hours, centrifuge to obtain the filtrate, and pass the filtrate directly through the Sephadex column and 0001×7 ion exchange resin for filtration chromatography with a flow rate of 3ml / min, combined the filtrates, decolorized with 7% activated carbon, concentrated the filtrate under reduced pressure, and spray-dried to obtain notoginseng powder.

[0064] 2. Preparation of collagen-based composite hemostatic powder

[0065] (1) Notoginseng modif...

Embodiment 3

[0074] 1. Preparation of Panax notoginseng raw material

[0075] At an ultrasonic frequency of 40kHz and a power of 120w, immerse the notoginseng powder in 15 times the ethanol solution with a concentration of 90wt% for 18 hours, then repeatedly immerse it in 8 times the ethanol solution with a concentration of 90wt% for 10 hours, and let it stand for 0.8 hours to separate , combine the two extracts, and keep it for other use; dry the residue, add 18 times of water to soak for 18 hours; then use 8 times of water to repeatedly soak for 8 hours, centrifuge to obtain the filtrate, and pass the filtrate directly through the Sephadex column Perform filtration chromatography with 0001×7 ion exchange resin at a flow rate of 0.7ml / min, combine the filtrates, remove color with 5% activated carbon, concentrate the filtrate under reduced pressure, and spray dry to obtain notoginseng powder.

[0076] 2. Preparation of collagen-based composite hemostatic powder

[0077] (1) Notoginseng mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com