Method for preparing alanyl-glutamine injection

A technology of alanyl glutamine and injection, which is applied in the fields of pharmaceutical formulation, drug delivery, metabolic diseases, etc., can solve the problems of poor stability and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

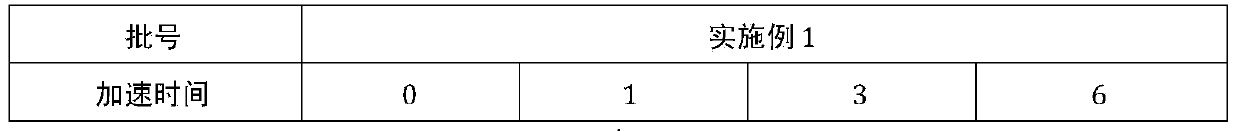

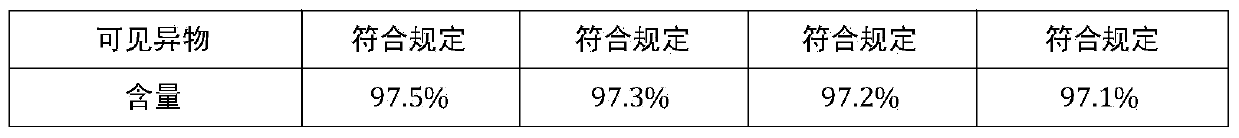

Embodiment 1

[0016] Example 1: Alanyl glutamine injection (10g:50ml).

[0017] Preparation: 1) Boil the water for injection, add 15L of water for injection into the concentrated preparation tank, cool down to 45°C, add 10kg of alanyl glutamine, stir for 30 minutes, after the raw materials are completely dissolved, add 0.05kg of moistened Wet the needles with activated carbon, stirred and adsorbed for 20 minutes, and poured into the diluted tank. Rinse the concentrated preparation tank 4 times with water for injection cooled below 45°C, and pull all the flushing water into the thin preparation tank; l Sodium hydroxide solution to adjust the ph value to 5.7, add 0.05kg of wetted activated carbon for needles, add water for injection to the full amount, and cycle for 40 minutes; 3) Sampling to detect endotoxin, content, and ph value; 4) Semi-finished product inspection Filling after passing the test, 50ml / bottle, the filling temperature is controlled at 50°C; 5) Sterilize at 115°C for 30 minu...

Embodiment 2

[0018] Example 2: Alanyl glutamine injection (20g:100ml).

[0019] Preparation: 1) Boil water for injection, add 30L of water for injection into the concentrated preparation tank, cool down to 45°C, add 20kg of alanylglutamine, stir for 30 minutes, after the raw materials are completely dissolved, add 0.15kg of moistened Wet the needles with activated carbon, stirred and adsorbed for 20 minutes, and poured into the diluted tank. Rinse the concentrated preparation tank 4 times with the water for injection cooled below 45°C, and pull all the flushing water into the thin preparation tank; 2) After the liquid medicine in the concentrated preparation tank is finished, add water for injection to 90L, and use 0.1mol / l Sodium hydroxide solution to adjust the pH value to 5.8, add 0.15 kg of wetted activated carbon for needles that absorbs 5% of its mass trans-lycopene, add water for injection to the full amount, and cycle for 40 minutes; 3) Sampling to detect endotoxin, content, and ...

Embodiment 3

[0020] Example 3: Alanyl glutamine injection (20g:100ml).

[0021] Preparation: 1) Boil water for injection, add 30L of water for injection into the concentrated preparation tank, cool down to 45°C, add 20kg of alanylglutamine, stir for 30 minutes, after the raw materials are completely dissolved, add 0.15kg of moistened Wet the needles with activated carbon, stirred and adsorbed for 20 minutes, and poured into the diluted tank. Rinse the concentrated preparation tank 4 times with the water for injection cooled below 45°C, and pull all the flushing water into the thin preparation tank; 2) After the liquid medicine in the concentrated preparation tank is finished, add water for injection to 90L, and use 0.1mol / l Sodium hydroxide solution to adjust the ph value to 5.8, add 0.15 kg of wetted activated carbon for needles that absorbs cis-lycopene accounting for 5% of its mass, add water for injection to the full amount, and pull the cycle for 40 minutes; 3) Sampling to detect en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com