Method and system for measuring humidity of high-temperature high-pressure high-humidity gas

A technology of high temperature, high pressure and gas temperature, applied in the direction of analyzing materials, instruments, etc., can solve the problem of uncertainty in the linearity of moisture-sensing components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

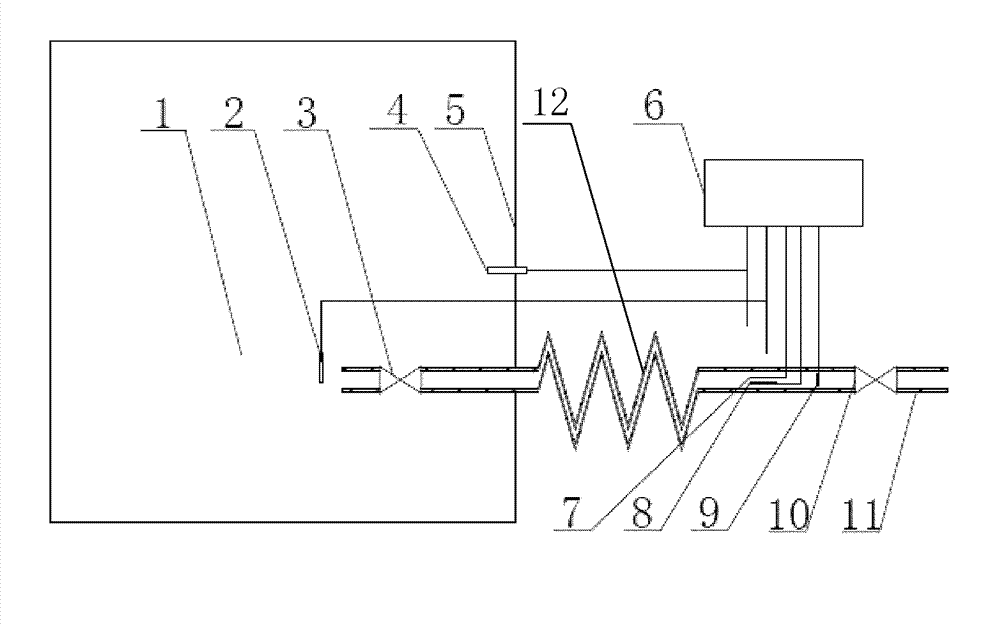

[0025] Example 1 (High temperature, high pressure and high humidity gas humidity measurement):

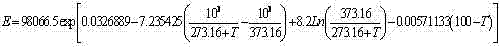

[0026] According to the attached figure 1 Arrange temperature, pressure and humidity measuring points. Among them, the temperature sensor 7 and the humidity sensor 8 may also be a temperature and humidity sensor. The temperature value of the heat-tracing insulation pipeline 11 is set to 110°C, and the pressure reduction value of the pressure reducing regulator 3 is set to an absolute pressure of 1.2 atm. The pressure reducing and stabilizing valve is preferably arranged at the inlet of the pipeline. The opening degree of the discharge device, which is preferably arranged at the end of the pipeline, is adjusted so that the gas is discharged at a smaller flow rate. The discharge device is preferably a needle valve 10. At this time, the partial pressure of the steam after pressure reduction e 1 =0.849 atm; temperature T 1 =108℃; pressure P 1 =1.21atm; the temperature T in the pressu...

Embodiment 2

[0039] Example 2 (Analysis of saturated and partially condensed gas):

[0040] Embodiment 2 is similar to Embodiment 1, and the same parts of the two will not be repeated. According to the attached figure 1 Arrange temperature, pressure and humidity measuring points. Among them, the temperature sensor 7 and the humidity sensor 8 may also be a temperature and humidity sensor. The temperature value of the heat-tracing insulation pipeline 11 is set to 120°C, and the pressure reduction value of the pressure reducing regulator 3 is set to an absolute pressure of 1.2 atm. Adjust the opening of the needle valve 10 to discharge the gas at a smaller flow rate. At this time, the partial pressure of the steam after pressure reduction e 1 =0.915 atm; temperature T 1 =120℃; pressure P 1 =1.20atm; temperature T in the pressure vessel 0 =140℃; pressure P 0 =6.0atm.

[0041] According to the measured parameters, the method steps to calculate the humidity and other parameters of the measured h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com