Spinning manifold for manufacturing POY (pre-oriented yarn) and FDY (fully drawn yarn) composite fibers

A composite fiber and spinning box technology, applied in the field of spinning boxes, can solve the problem of difficulty in ensuring that the production capacity and production efficiency of POY and FDY composite yarns are not affected, and achieve the effects of high product quality, increased moisture absorption and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

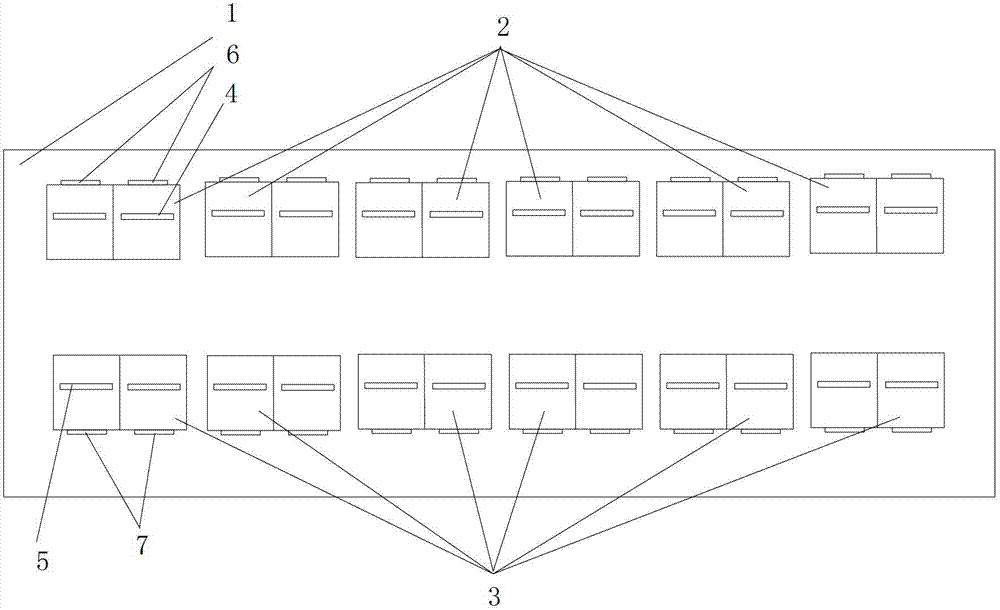

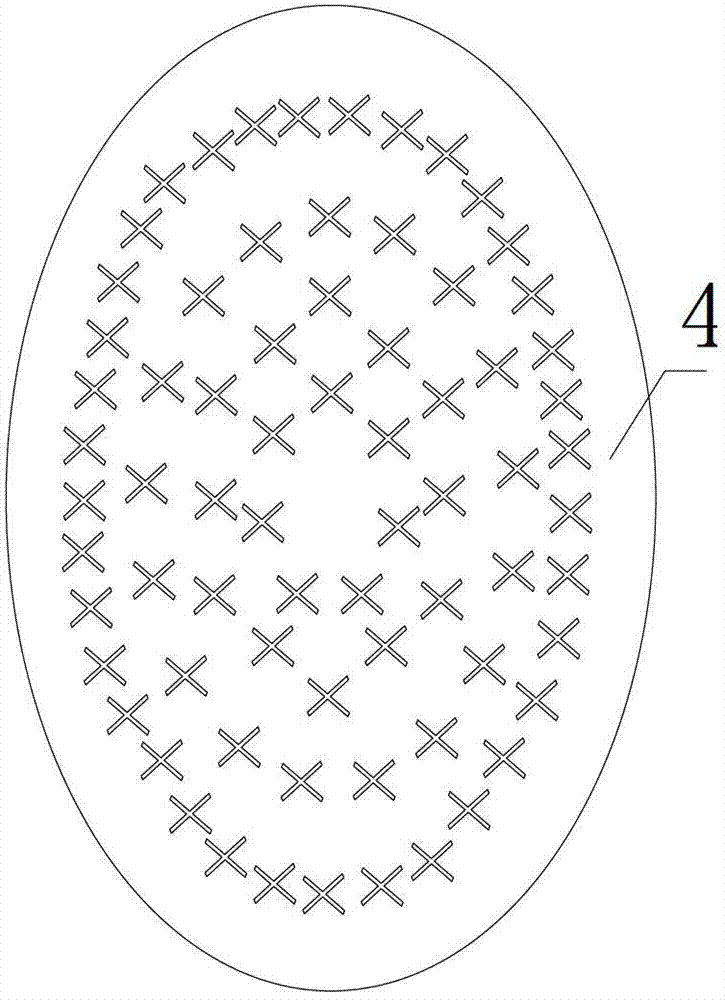

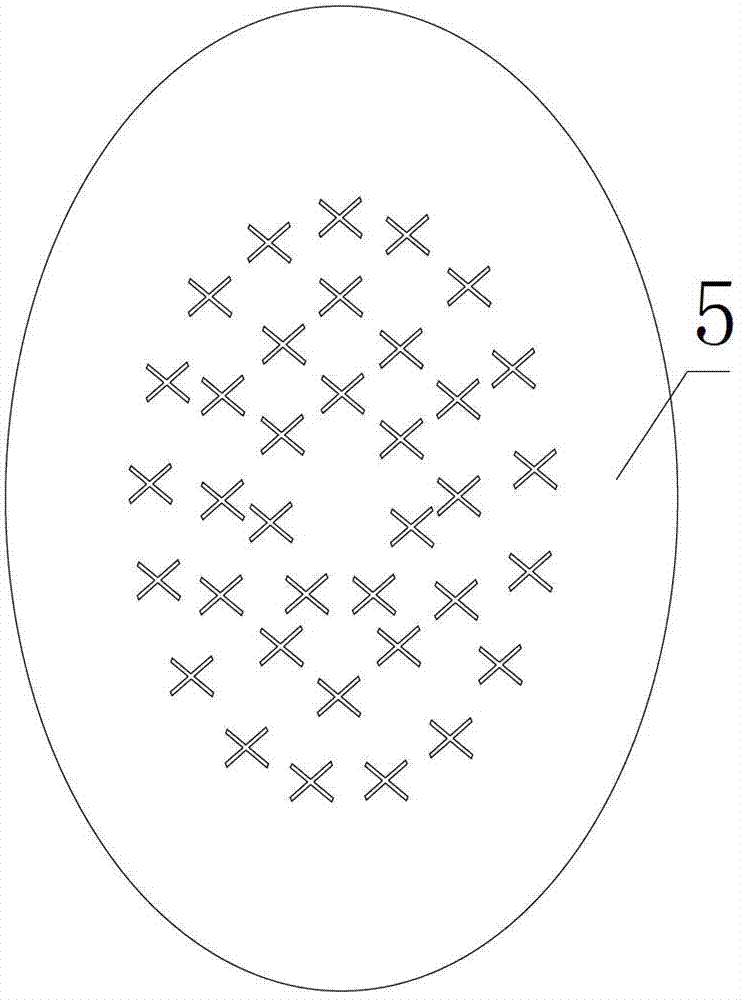

[0017] Such as figure 1 As shown, a spinning box for producing POY and FDY composite fibers, the spinning box includes a spinning box body 1, a melt distribution pipe, a metering pump and a spinning assembly, and the spinning assembly 2 and the spinning assembly for producing POY silk The spinning assembly 3 for producing FDY filaments is arranged in parallel in double rows, and each spinning assembly 2 for producing POY filaments is provided with two spinnerets 4 for spinning, and each spinning assembly 3 for producing FDY filaments Two spinnerets 5 are provided for spinning. There are 6 spinning assemblies 2 for producing POY filaments, and 6 spinning assemblies 3 for producing FDY filaments. The spinneret is placed horizontally in the spinning assembly, and the spinning assembly is provided with a feed inlet on the side of the spinning box, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com