Four-stroke outboard engine oil lubricating oil capable of satisfying NMMA FC-W specification

An engine oil, four-stroke technology, applied in the directions of lubricating compositions, petroleum industry, additives, etc., can solve the problems of water environment pollution, the difficulty of two-stroke outboard engines to meet the needs of the development of outboard engines, etc., to ensure safety, environmental protection, Excellent shear resistance, small viscosity change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The specific component content of the four-stroke outboard motor oil composition of the present embodiment is as follows:

[0056]

[0057]The preparation method is as follows: mixing each component at 55° C. and fully stirring for 3 hours until the composition is uniformly stirred.

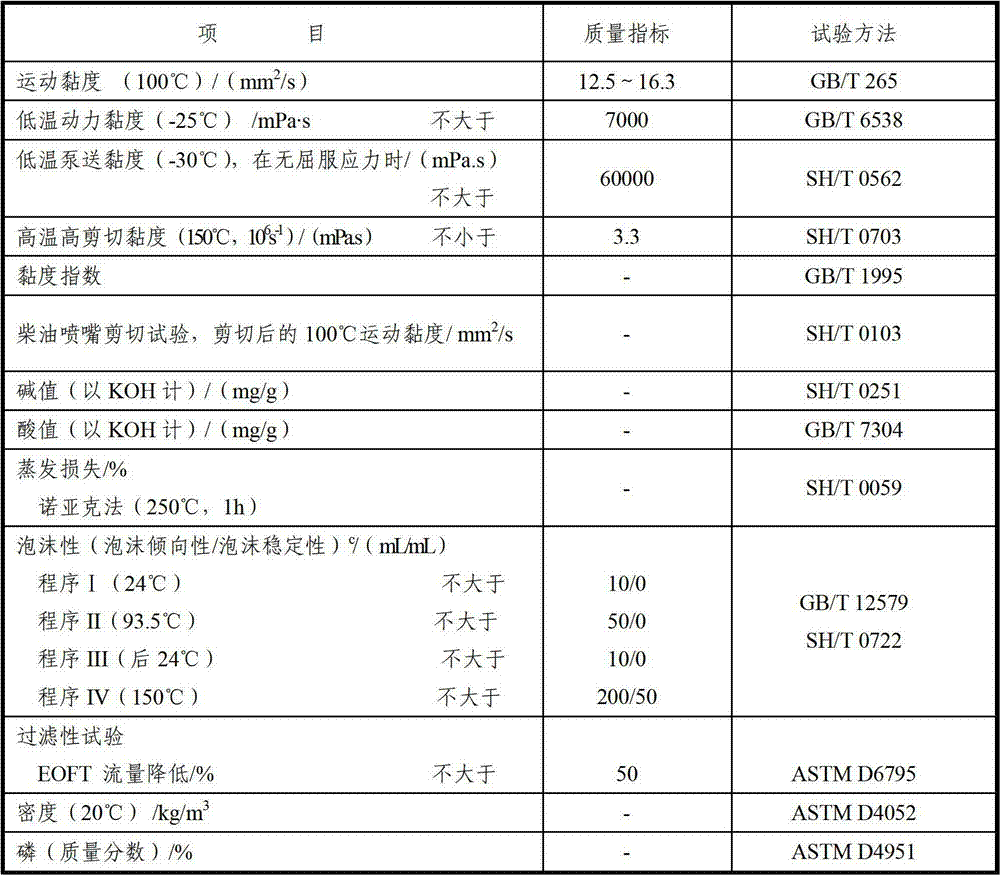

[0058] After testing, the performance data of the four-stroke outboard engine oil composition of this embodiment are shown in Table 5.

[0059] Physicochemical analysis and bench test data of the outboard motor oil composition of table 5 embodiment 1

[0060]

[0061]

Embodiment 2

[0063] The specific component content of the four-stroke outboard motor oil composition of the present embodiment is as follows:

[0064]

[0065] After testing, the performance data of the four-stroke outboard engine oil composition of this embodiment are shown in Table 6.

[0066] Table 6 Embodiment 2 Outboard engine oil combination physical and chemical analysis and bench test data

[0067]

[0068]

Embodiment 3

[0070] The specific component content of the four-stroke outboard motor oil composition of the present embodiment is as follows:

[0071]

[0072] After testing, the performance data of the four-stroke outboard engine oil composition of this embodiment are shown in Table 7.

[0073] Physicochemical analysis and bench test data of table 7 embodiment 3 outboard motor oil composition

[0074]

[0075]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com