A kind of preparation method of thermosensitive fluorescent polymer

A fluorescent polymer and temperature-sensitive technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of easy demulsification into flocs, difficult removal of emulsifier residues, and difficulty in formulating small particle size emulsification systems. Achieve the effects of mild reaction conditions, high reaction yield and good monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

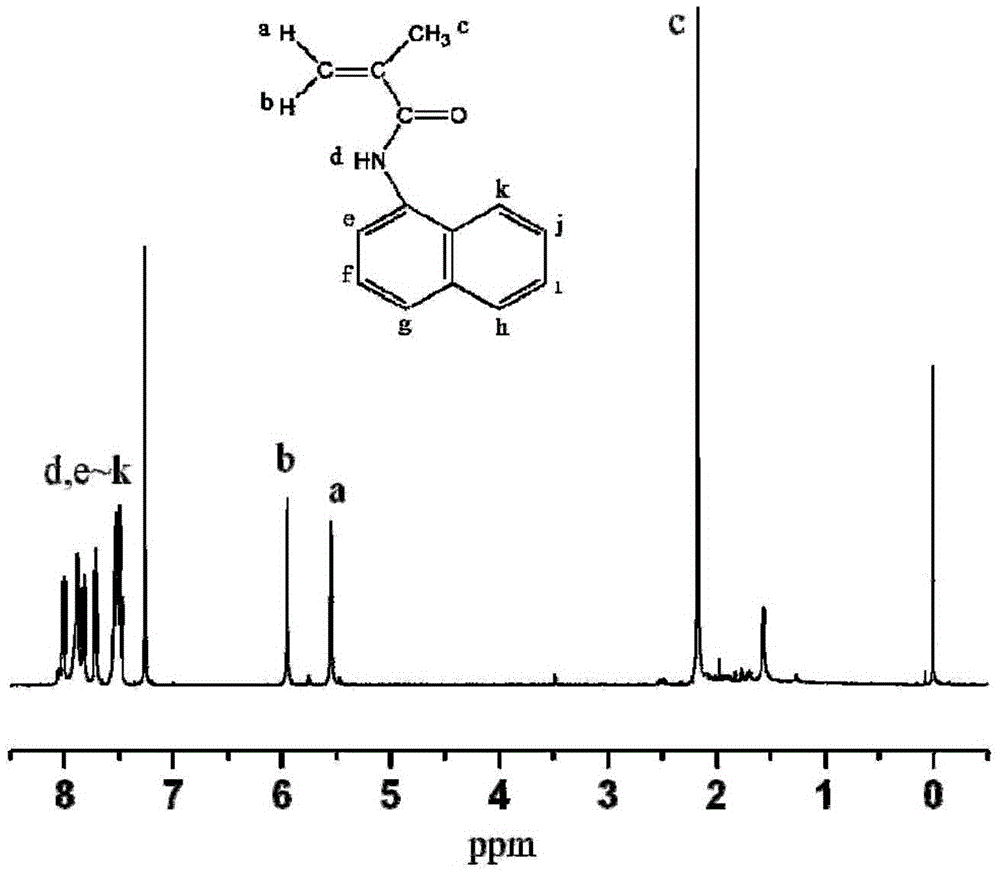

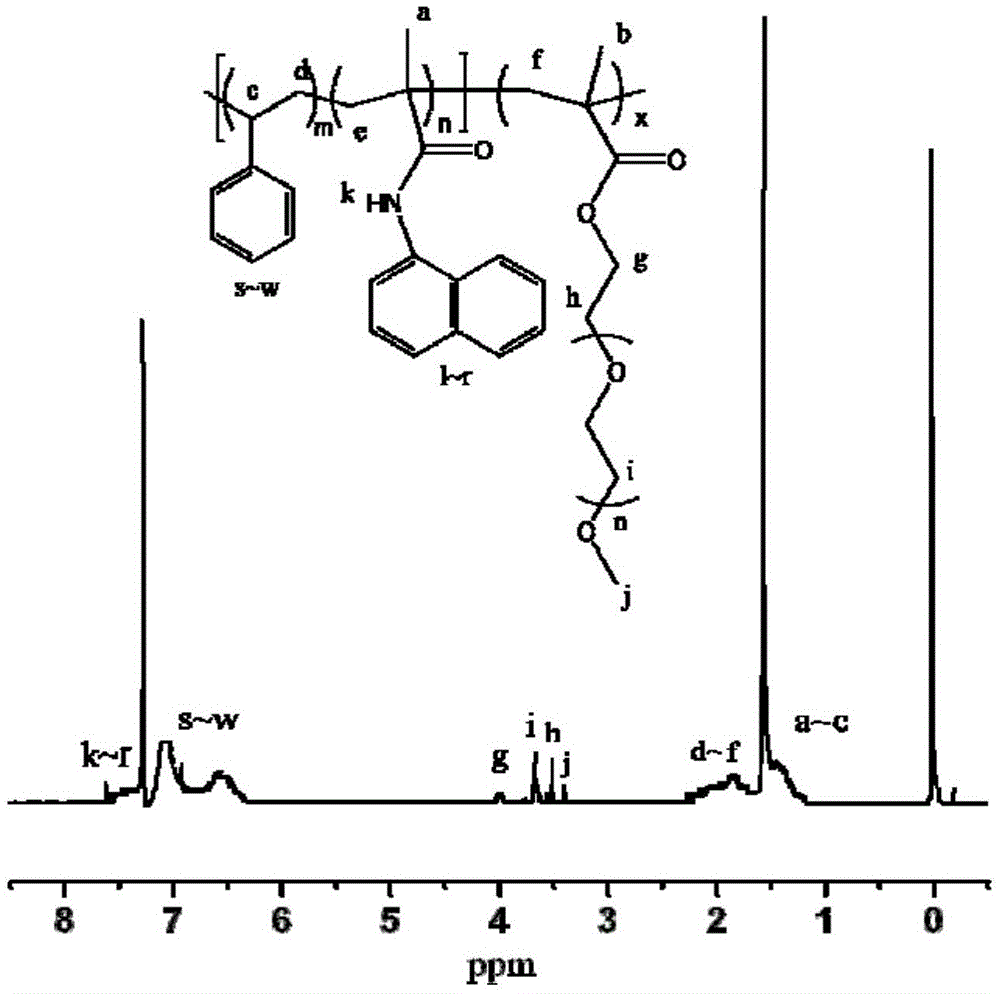

[0037] (1) Synthesis of NMA monomer: Add 1.4319g (0.01moL) N-α-naphthylamine, 100mL benzene and 1.67mL (0.012moL) to a 250mL two-neck flask equipped with a dropping funnel, condenser, and magnetic stirrer Triethylamine, magnetically stirred in an ice bath until uniform to 0 °C. Continue stirring in the ice bath, and slowly add 1.16 mL (0.01 moL) of methacryloyl chloride dissolved in 15 mL of benzene into the above mixed solution with a dropping funnel. Heat the mixture to 40°C, react for 2 hours and cool to room temperature, filter to remove the formed triethylamine hydrochloride solid, collect the filtrate in a separatory funnel, and wash with distilled water, dilute hydrochloric acid, and dilute NaHCO successively 3 Wash each solution 3 times, add 5g of anhydrous magnesium sulfate, stir and dry, filter to obtain the product benzene solution, remove the solvent benzene by rotary evaporation to obtain a crude product, recrystallize in methanol 3 times to obtain 1.904g of white...

Embodiment 2

[0042] Steps (1) to (3) are the same as in Example 1.

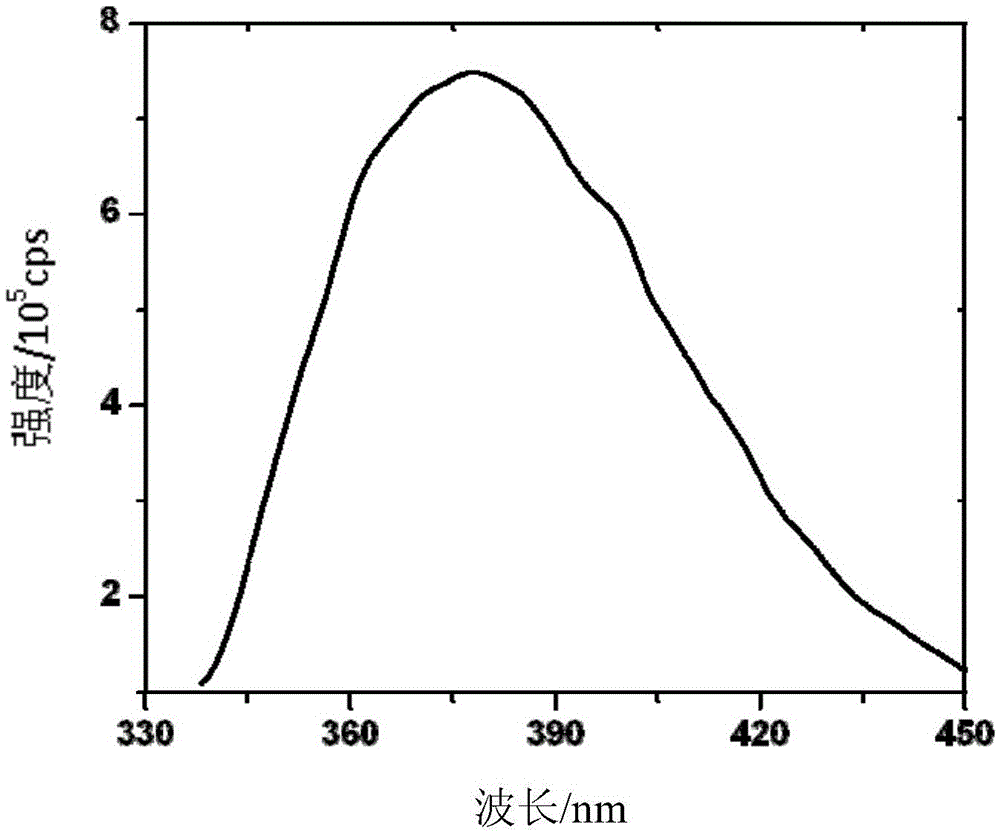

[0043] Step (4) P(St-co-NMA) m -b-PPEGMA n Preparation of nanospheres: prepare 1mL2mg / mLP (St 83 -co-NMA 4 )-PPEGMA 18 / THF solution, slowly drop 50 μL of the above THF solution into 2 mL of deionized water stirred at high speed, stir at a constant speed with the open mouth open for 24 hours, and obtain P(St 83 -co-NMA 4 )-PPEGMA 18 Aqueous solution of nanoparticles. According to the DLS test, the particle size of nano-microspheres is 86nm at 25°C, and the particle size decreases continuously as the temperature rises gradually within the temperature range of 25-60°C.

Embodiment 3

[0045] Steps (1) to (3) are the same as in Example 1.

[0046] Step (4) P(St-co-NMA) m -b-PPEGMA n Preparation of nanospheres: prepare 1mL5mg / mLP (St 83 -co-NMA 4 )-PPEGMA 18 / 1,4-dioxane solution, slowly drop 50 μL of the above-mentioned dioxane solution into 2 mL of deionized water stirred at high speed, stir at a constant speed for 24 hours, and obtain P( St. 83 -co-NMA 4 )-PPEGMA 18 Aqueous solution of nanoparticles. The particle size of the nano-microspheres was 118nm at 25°C by DLS test, and the particle size decreased continuously when the temperature was gradually raised within the temperature range of 25-60°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com