Deep oxidation treatment method and apparatus for difficultly-degraded organic chemical industry wastewater

An organic chemical and deep oxidation technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of high operating costs, effluent CODcr exceeding the standard, and high equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

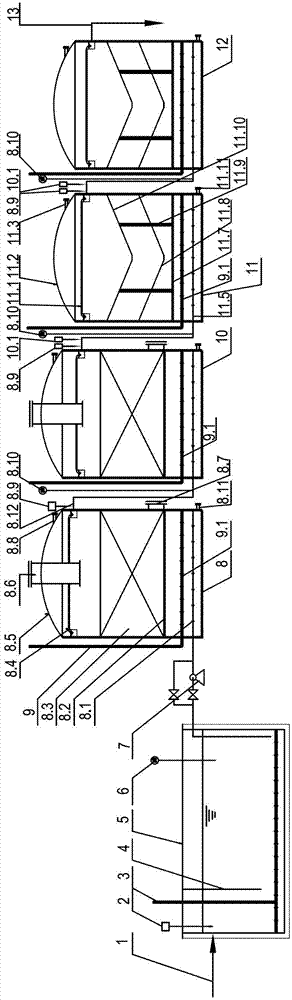

[0039] Such as figure 1 The shown deep oxidation treatment device for refractory organic chemical wastewater includes an acidification and sterilization pool 5 connected sequentially through pipelines, a primary enhanced electrochemical reactor 8, a secondary enhanced electrochemical reactor 10, and a primary multiphase Catalytic oxidation reactor 11, secondary heterogeneous catalytic oxidation reactor 12, secondary heterogeneous catalytic oxidation reactor 12 is connected to the outlet pipe 13, and the outlet water through the outlet pipe 13 enters the follow-up conventional neutralization coagulation sedimentation and finally completes the mud-water separation .

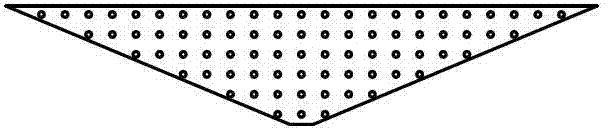

[0040] The first-level enhanced electrochemical reactor 8, the second-level enhanced electrochemical reactor 10, the first-level heterogeneous catalytic oxidation reactor 11, and the second-level heterogeneous catalytic oxidation reactor 12 are all installed inside the aeration main pipeline 9. An aeration pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com