Method for preparing CIGS powder through dry method

A technology of powder and dry method, which is applied in the field of CIGS powder preparation, which can solve the problems of solvent pollution, high requirements for preparation conditions, and difficult control, and achieve the effects of low cost, high purity, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

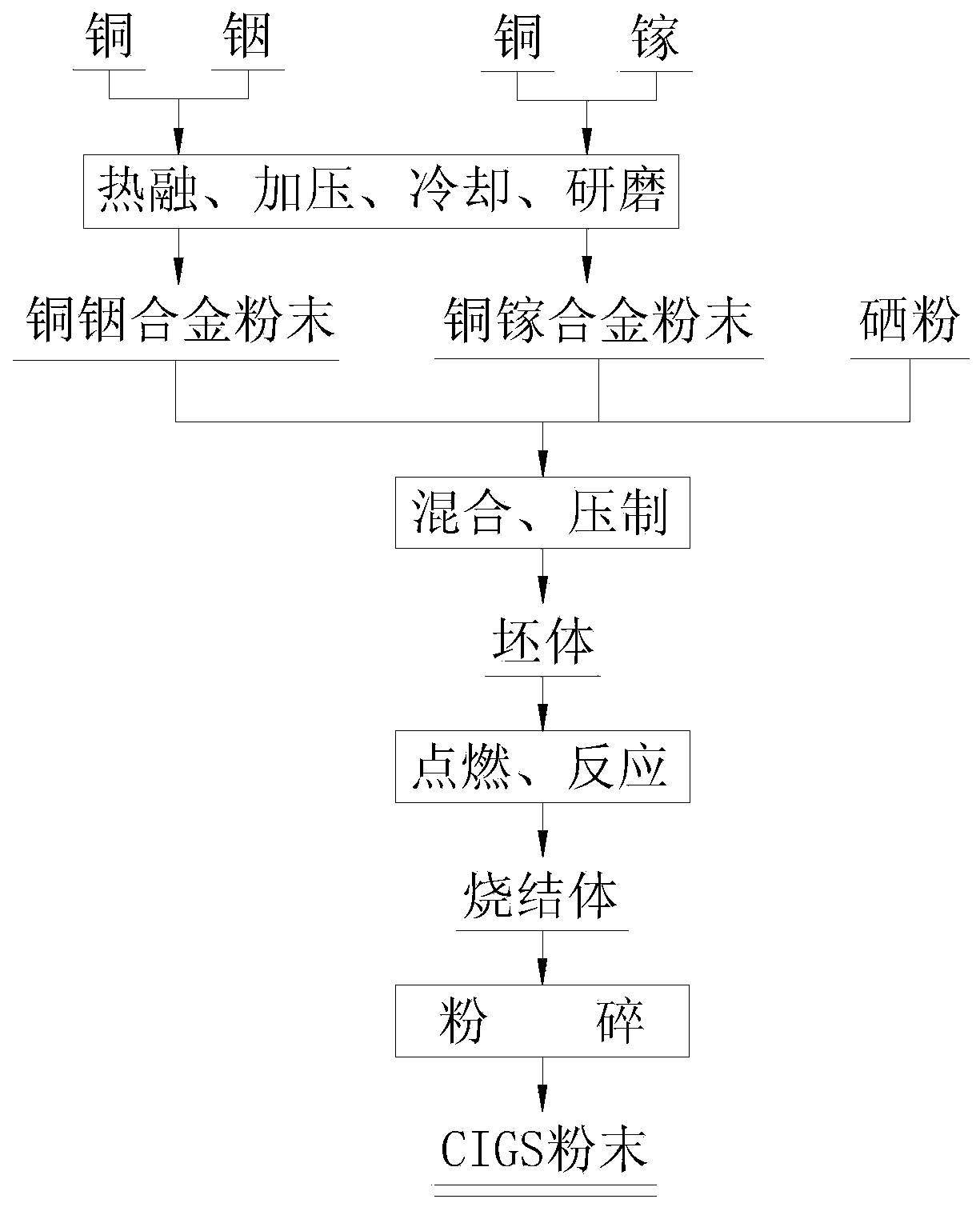

[0025] Combine below figure 1 Introduce the method of the present invention in detail, it comprises the following steps:

[0026] First, after mixing copper powder and indium powder evenly, heat-melt, pressurize, cool, and grind under vacuum conditions to obtain copper-indium alloy powder; after mixing copper powder and gallium powder evenly, heat-melt under vacuum conditions , pressurization, cooling, and grinding to obtain copper-gallium alloy powder; in order to achieve the required powder particle size, the above process should be carried out several times; then copper-indium alloy powder, copper-gallium alloy powder and selenium powder are mixed evenly to obtain copper-indium alloy powder Gallium-selenide mixture, the mixture made in this way will not cause severe toxicity and explosion problems, and can be used for hot-melt pressure forming targets. In the implementation process, copper: indium: gallium: selenium should be proportioned according to the material ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com