Corrosion inhibitor

A technology of corrosion inhibitor and water quality stabilizer, applied in the field of corrosion inhibitor, can solve problems such as environmental pollution, and achieve the effects of strong adaptability, excellent corrosion inhibition, and excellent anti-scaling function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

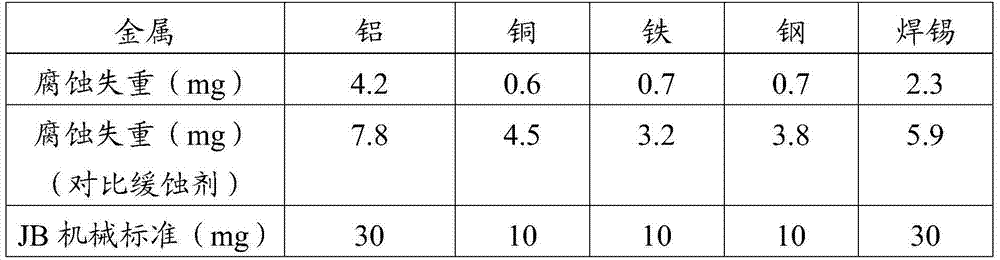

Image

Examples

Embodiment 1

[0023] The embodiment of the present invention provides a kind of corrosion inhibitor, and described corrosion inhibitor comprises the following mass percentage material:

[0024] Fluoride salt 1%-8%, molybdate 0.5%-1.5%, water quality stabilizer 0.0008-0.001%, borate 0.15-0.25%, silicate 0.25%-0.35%, carboxylate 0.3%-2.5% , Aromatic azoles 3%-5%, the balance is deionized water.

[0025] In the embodiment of the present invention, the fluorine salt and molybdate contained in the corrosion inhibitor belong to the anodic corrosion inhibitor in the inorganic corrosion inhibitor. Compared with the nitrite and chromate corrosion inhibitors, the fluoride and molybdate Salt has the advantages of low toxicity, harmlessness and good stability. They can effectively form a dense protective film on the surface of metals or alloys to prevent the corrosion of metals or alloys (especially magnesium alloys) by ethylene glycol decomposition products; Scale substances form stable complexes, w...

Embodiment 2

[0037] The embodiment of the present invention provides a kind of corrosion inhibitor, and described corrosion inhibitor comprises the following mass percentage material:

[0038] Sodium fluoride 5%, sodium molybdate 0.97%, polymaleic anhydride 0.0009%, sodium tetraborate 0.2%, sodium silicate 0.35%, sodium benzoate 1.3%, sodium methylbenzotriazole nitrogen 3.7%, the balance is Deionized water.

[0039] The concrete preparation steps of this corrosion inhibitor are as follows:

[0040] Add 5% sodium fluoride and 0.97% sodium molybdate into the beaker and stir until uniform. Then add 0.0009% polymaleic anhydride, 0.2% sodium tetraborate, 0.35% sodium silicate, 1.3% sodium benzoate and 3.7% sodium methylbenzotriazole nitrogen to the mixed material, and continue stirring until well mixed. Finally, the remaining amount of deionized water is added to the uniformly mixed materials within 30 minutes, and the desired composite corrosion inhibitor of the present invention can be obt...

Embodiment 3

[0049] The embodiment of the present invention provides a kind of corrosion inhibitor, and described corrosion inhibitor comprises the following mass percentage material:

[0050] Potassium fluoride and sodium fluoride compound 8%, potassium molybdate 0.5%, polyacrylate 0.001%, sodium metaborate 0.25%, sodium silicate 0.25%, sodium gluconate 0.3%, mercaptobenzotriazepam azole 3%, the balance is deionized water.

[0051] Concrete preparation steps are as follows:

[0052] A compound of potassium fluoride and sodium fluoride with a mass fraction of 8% (the ratio of potassium fluoride to sodium fluoride is optional) and 0.5% potassium molybdate, 0.001% polyacrylate, 0.25% Sodium metaborate, 0.25% sodium silicate, 0.3% sodium gluconate and 3% mercaptobenzotriazole were added into the beaker, and stirred until uniformly mixed. Then add the remaining amount of deionized water into the uniformly mixed material within 40 minutes, and after stirring evenly, the desired corrosion inhi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com