High-capacity RE-Mg-Ni-Co based hydrogen storage alloy and preparation method thereof

A re-mg-ni-co, hydrogen storage alloy technology, applied in the field of high-capacity RE-Mg-Ni-Co-based hydrogen storage alloys and their preparation, can solve the problems of reducing alloy hydrides, no reversible hydrogen absorption and desorption, etc. , achieve high hydrogen absorption and desorption capacity, and improve the kinetic performance of hydrogen absorption and desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

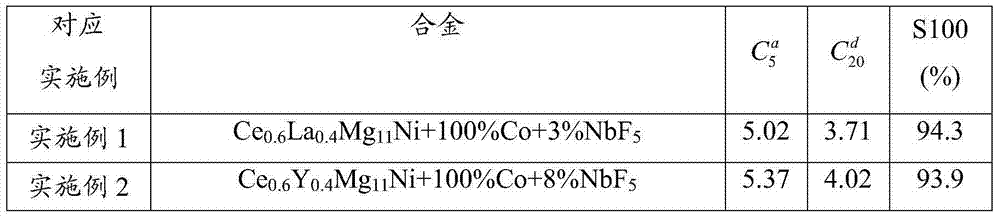

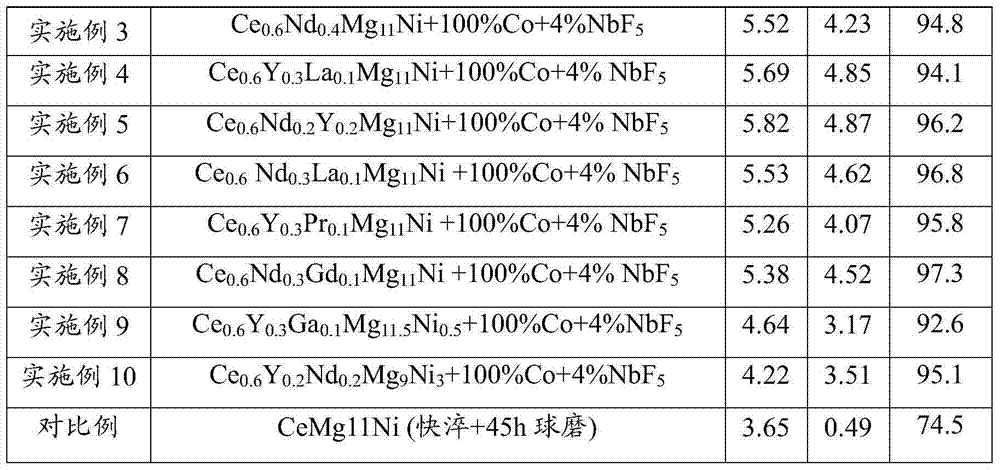

Embodiment 1

[0029] According to the chemical formula Ce 0.6 La 0.4 Mg 11 Ni is selected from bulk metal magnesium, metal nickel, rare earth metal cerium and lanthanum. These metals have a purity of ≥99.8% and are weighed according to chemical dosage ratios. The crucible capacity of the melting furnace is about 2 kg, and the ingredients are calculated as 2 kg per furnace. Weigh 1240.0g of metal magnesium, 252.0g of metal nickel, 379.3g of metal cerium, and 250.5g of metal lanthanum, put them in the magnesium oxide crucible of the intermediate frequency induction furnace, then cover the furnace cover, and vacuumize for about 40 minutes to a vacuum degree of 5×10 -3 Above Pa, then fill helium protective gas until the air pressure reaches 0.04MPa negative pressure, adjust the power to 5kW, control the temperature at about 700°C to melt the metal magnesium, then adjust the power to 25kW, and control the temperature at 1600°C to make metal nickel, Cerium and lanthanum melt. After the metal...

Embodiment 2

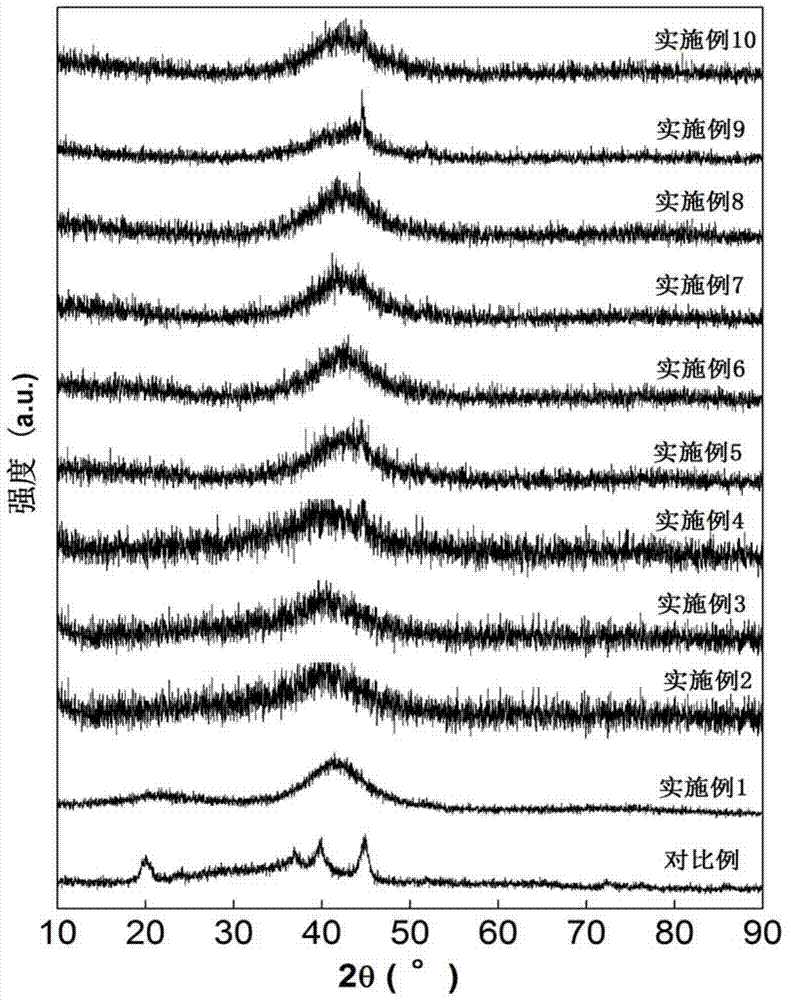

[0033] The alloy composition is: Ce 0.6 Y 0.4 Mg 11Ni, weigh 1295.5g of magnesium metal, 363.3g of nickel metal, 396.3g of cerium metal, and 167.5g of yttrium metal, and prepare alloy powder according to the method in Example 1. The difference is that nano-NbF 5 The addition amount of catalyst is 4g (8wt%). The structure of the alloy powder was tested by XRD, the results are shown in figure 1 The gaseous hydrogen absorption and desorption capacity and kinetics of the alloy powder were tested, and the results are shown in Table 1.

Embodiment 3

[0035] The alloy composition is: Ce 0.6 Nd 0.4 Mg 11 Ni, weigh 1234.4g of magnesium metal, 250.9g of nickel metal, 258.9g of neodymium metal, and 377.6g of cerium metal, and prepare alloy powder according to the method in Example 1. The difference is that nano-NbF 5 The addition amount of catalyst is 2g (4wt%). The structure of the alloy powder was tested by XRD, the results are shown in figure 1 The gaseous hydrogen absorption and desorption capacity and kinetics of the alloy powder were tested, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com