Normal-temperature activated rare earth hydrogen storage alloy and preparation method and application thereof

A hydrogen storage alloy and activation-type technology, which is applied in the field of materials, can solve the problems of high activation temperature, harsh activation treatment conditions, and unsuitability for mass production, and achieve high hydrogen absorption and desorption, suitable for mass production, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

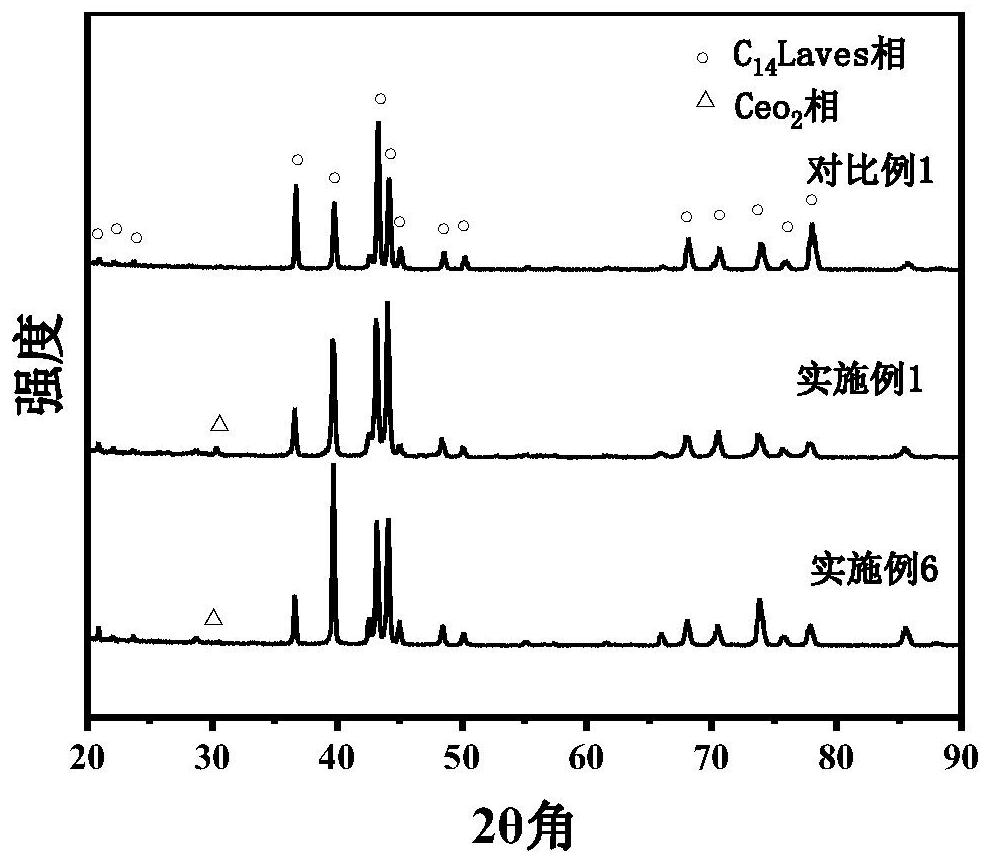

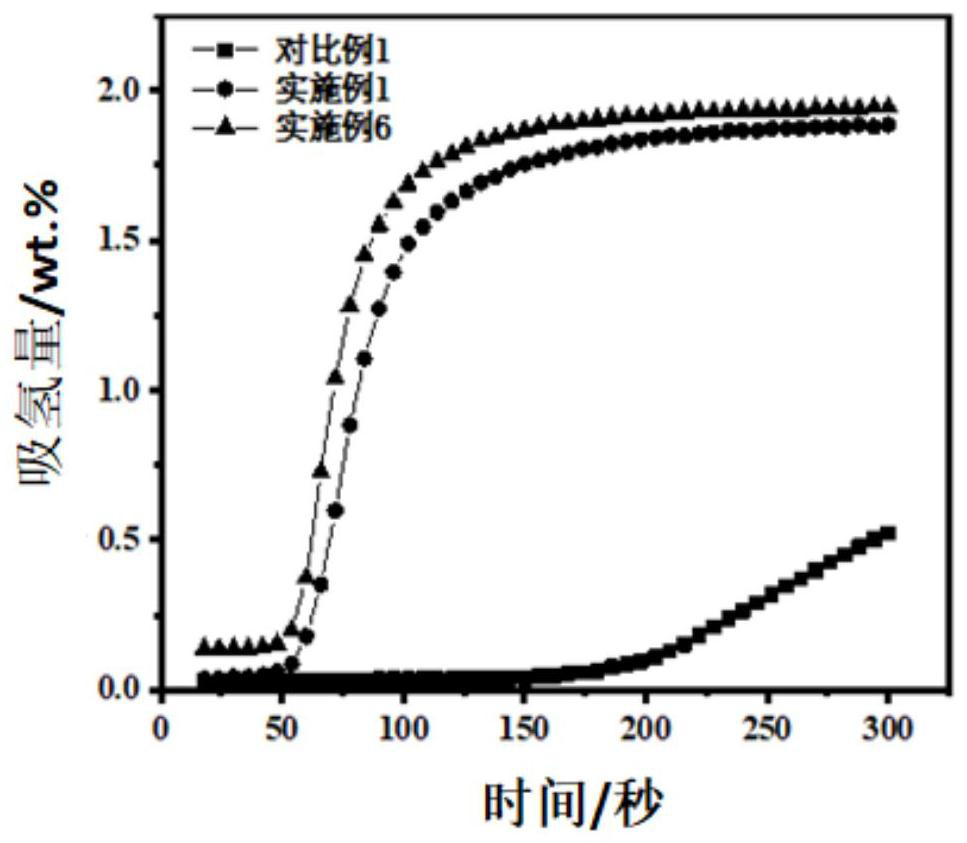

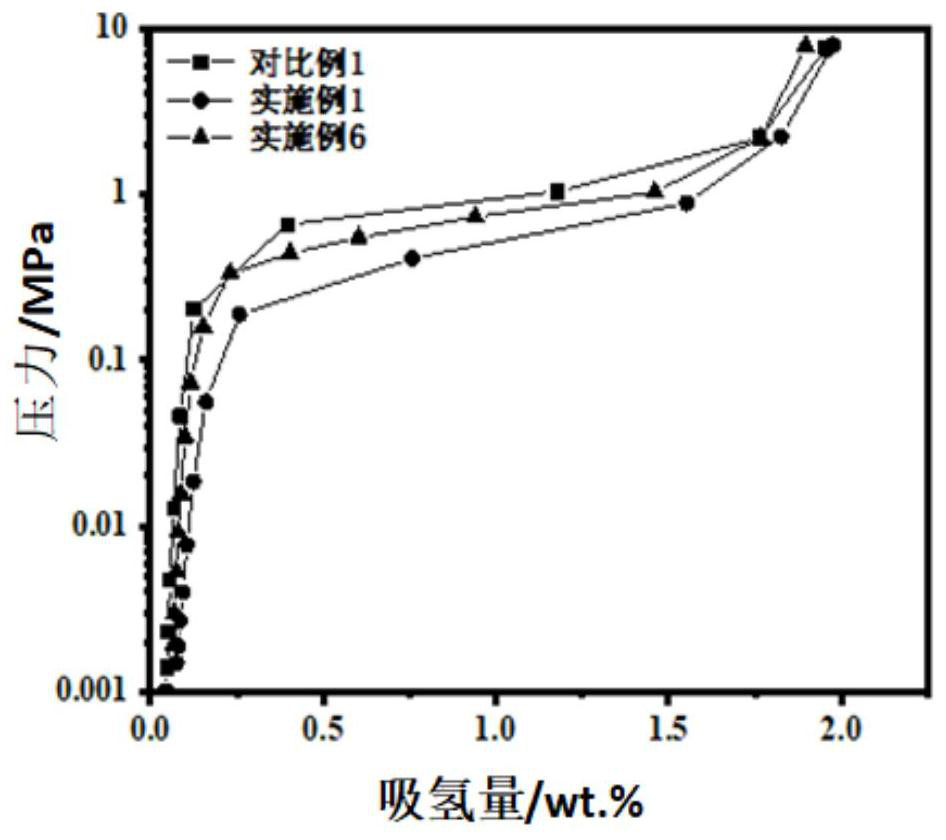

[0051] This embodiment provides a normal temperature activation type rare earth hydrogen storage alloy, the composition of the normal temperature activation type rare earth hydrogen storage alloy is: Ti 0.8 Zr 0.2 Cr 0.75 mn 1.25 Ce 0.02 , the preparation method of the normal temperature activation type rare earth hydrogen storage alloy comprises the following steps:

[0052] (1) According to the molar ratio of 0.8:0.2:0.75:1.25:0.02, Ti, Zr, Cr, Mn and rare earth element Ce are mixed, and a non-consumable electric arc furnace is used for a 200s primary smelting under an argon atmosphere. The smelting current It is 130A, after the copper crucible is cooled to room temperature, it is turned over, and the melting is repeated 4 times to obtain an alloy ingot;

[0053] (2) After evacuating to a vacuum degree of 0.0001Pa, argon gas is introduced, and the alloy ingots described in step (1) are annealed at 1100°C for 2.5 hours in an argon atmosphere; then placed in a PCT test at ...

Embodiment 2

[0056] This embodiment provides a normal temperature activation type rare earth hydrogen storage alloy, the composition of the normal temperature activation type rare earth hydrogen storage alloy is: Ti 0.7 Zr 0.3 Cr 0.7 mn 1.3 Ce 0.03 , the preparation method of the normal temperature activation type rare earth hydrogen storage alloy comprises the following steps:

[0057] (1) According to the molar ratio of 0.7:0.3:0.7:1.3:0.03, Ti, Zr, Cr, Mn and rare earth element Ce are mixed, and a non-consumable electric arc furnace is used for 150s of primary smelting in an argon atmosphere. The smelting current 150A, after the copper crucible is cooled to room temperature, it is turned over, and the melting is repeated 3 times to obtain an alloy ingot;

[0058] (2) After evacuating to a vacuum degree of 0.00008Pa, helium is introduced, and the alloy ingot described in step (1) is annealed at 1000°C for 3 hours in an argon atmosphere; then placed in PCT testing equipment at 20°C T...

Embodiment 3

[0060] This embodiment provides a normal temperature activation type rare earth hydrogen storage alloy, the composition of the normal temperature activation type rare earth hydrogen storage alloy is: Ti 0.6 Zr 0.4 Cr 1.0 mn 1.0 Ce 0.01 , the preparation method of the normal temperature activation type rare earth hydrogen storage alloy comprises the following steps:

[0061] (1) According to the molar ratio of 0.6:0.4:1.0:1.0:0.01, Ti, Zr, Cr, Mn and rare earth element Ce are mixed, and a non-consumable electric arc furnace is used for a 250s primary smelting under an argon atmosphere. The smelting current 100A, after the copper crucible is cooled to room temperature, it is turned over, and the melting is repeated 5 times to obtain an alloy ingot;

[0062] (2) After evacuating to a vacuum degree of 0.00009Pa, argon is introduced, and the alloy ingot described in step (1) is sequentially annealed at 1200°C for 2 hours under an argon atmosphere; then placed in PCT testing equ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com