Composite hydrogen storage material, its preparation method and application

A hydrogen storage material, tih1.971 technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of low hydrogen storage efficiency and inability to store hydrogen, and achieve low cost of raw materials, simple operation, and simple preparation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

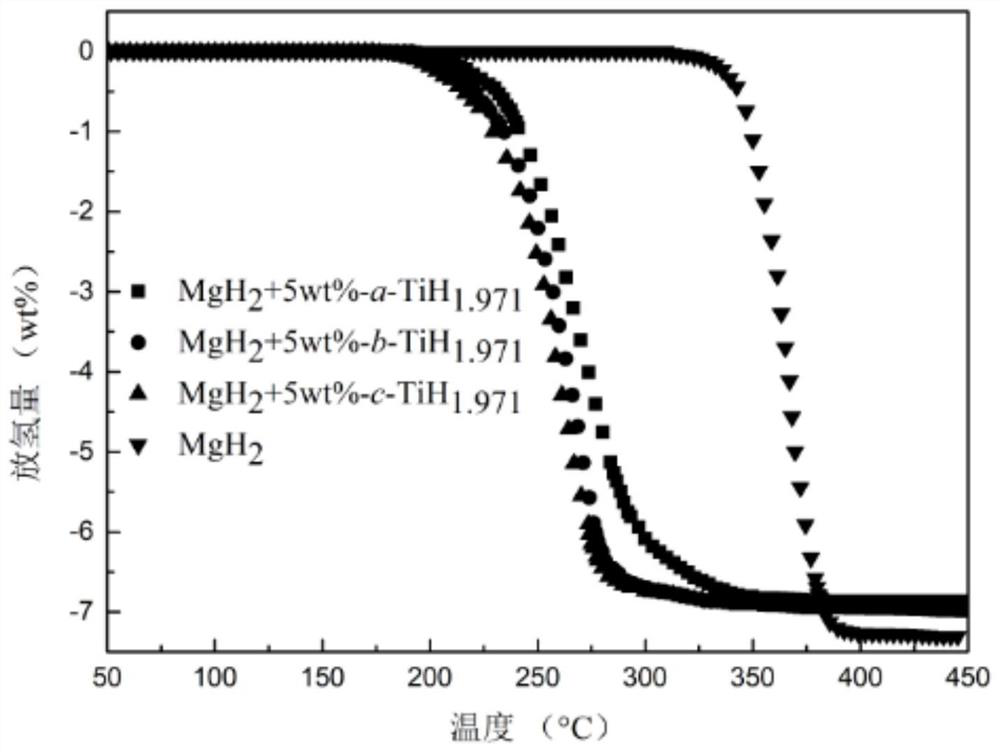

[0029] Study on the effect of ball milling time on TiH 1.971 Improve MgH 2 Influence of temperature rise on hydrogen desorption performance:

[0030] First prepare TiH 1.97 Particles: TiH 1.971 Powder mixed with oleic acid, oleylamine and heptane, TiH 1.971 The volume ratio of oleic acid, oleylamine and heptane is 1:0.33~1:10~1:20, continuous ball milling at 300~500rpm for 10~60h, TiH 1.971 The mass ratio to the steel ball used for ball milling is 1:45~60; the sample after ball milling is cleaned and left to stand to remove the supernatant, and the remaining solid is washed and treated and dropped into the liquid tube with oleic acid, oleylamine and heptyl Mixed solvent for cleaning, in which the volume ratio of oleic acid, oleylamine and heptane is 1:0.33~1:10~1:50, in order to prevent too much heptane, it is difficult to fully mix with the material, so it is divided into two times Drop in, shake and mix after each drop, suck out, perform the second drop, and finally dro...

Embodiment 2

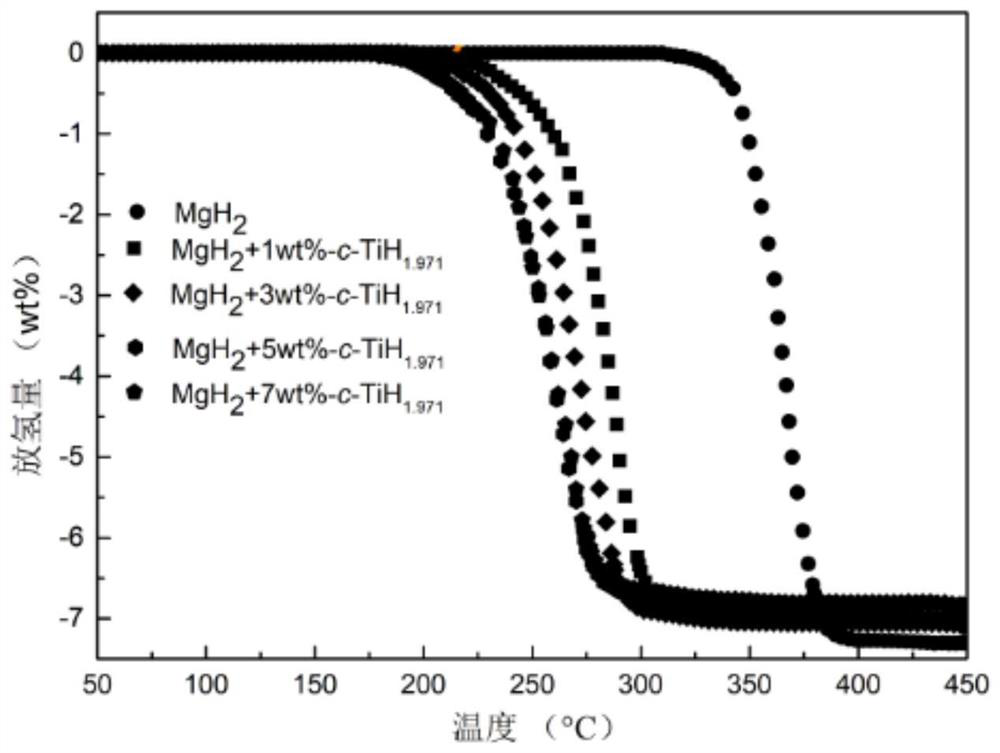

[0035] Study the effect of doping ratio on TiH 1.971 Improve MgH 2 Influence of temperature rise on hydrogen desorption performance:

[0036] TiH was ball milled for 60h 1.971 The proportion is 1wt% ~ 15wt% and MgH 2 Mix ball mill. With a mass ratio of 40:1 ball to material, put 2g of sample into it, mark it well, and run the ball mill jar forward and reverse alternately for 30 minutes at a speed of 450 rpm, but stop for 6 minutes during the alternation. After ball milling for two hours, crush the agglomerated sample in the tank; then after ball milling for two hours, take out the sample and keep it sealed in a glove box.

[0037]150-250 mg of catalyst composite system samples doped with a ratio of 1-15 wt % were weighed in the kit respectively. After the sample is put into the device, it is evacuated, the leak is picked up, and the test is started, and the temperature is raised to 450°C at a rate of 2°C / min through the program.

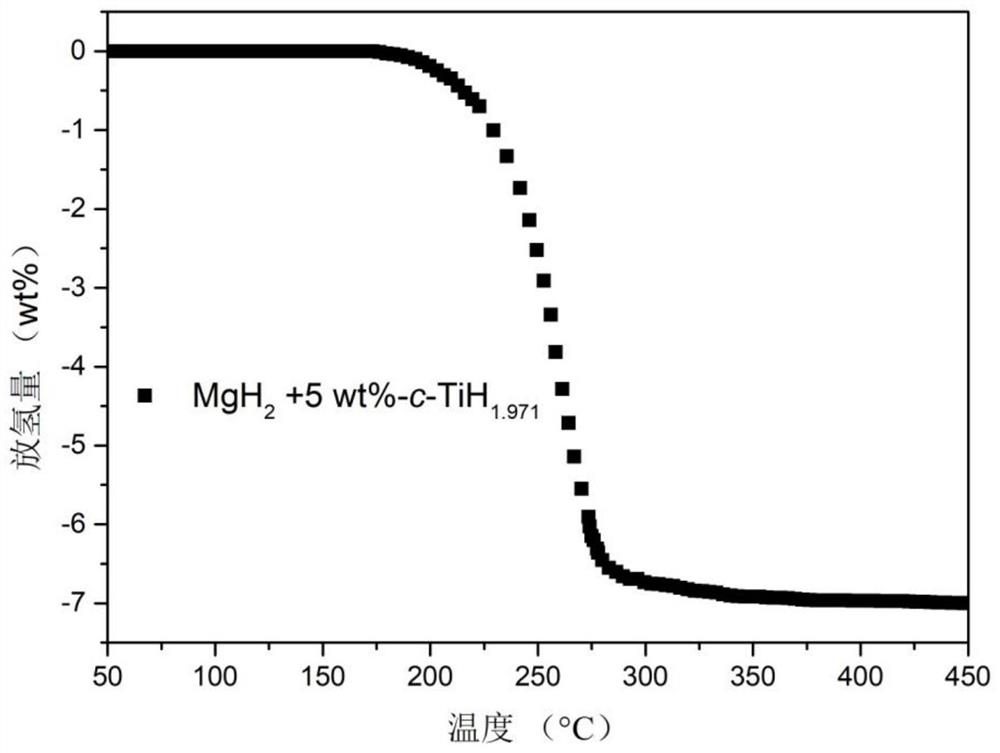

[0038] Such as figure 2 The hydrogen d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com