Composite hydrogen storage material as well as preparation method and application thereof

A hydrogen storage material and uniform mixing technology, applied in the field of composite hydrogen storage materials and its preparation, can solve the problems of limited hydrogen absorption and desorption kinetics, high thermodynamic stability, etc., and achieve good low-temperature hydrogen absorption and desorption kinetics, The effect of simple operation and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

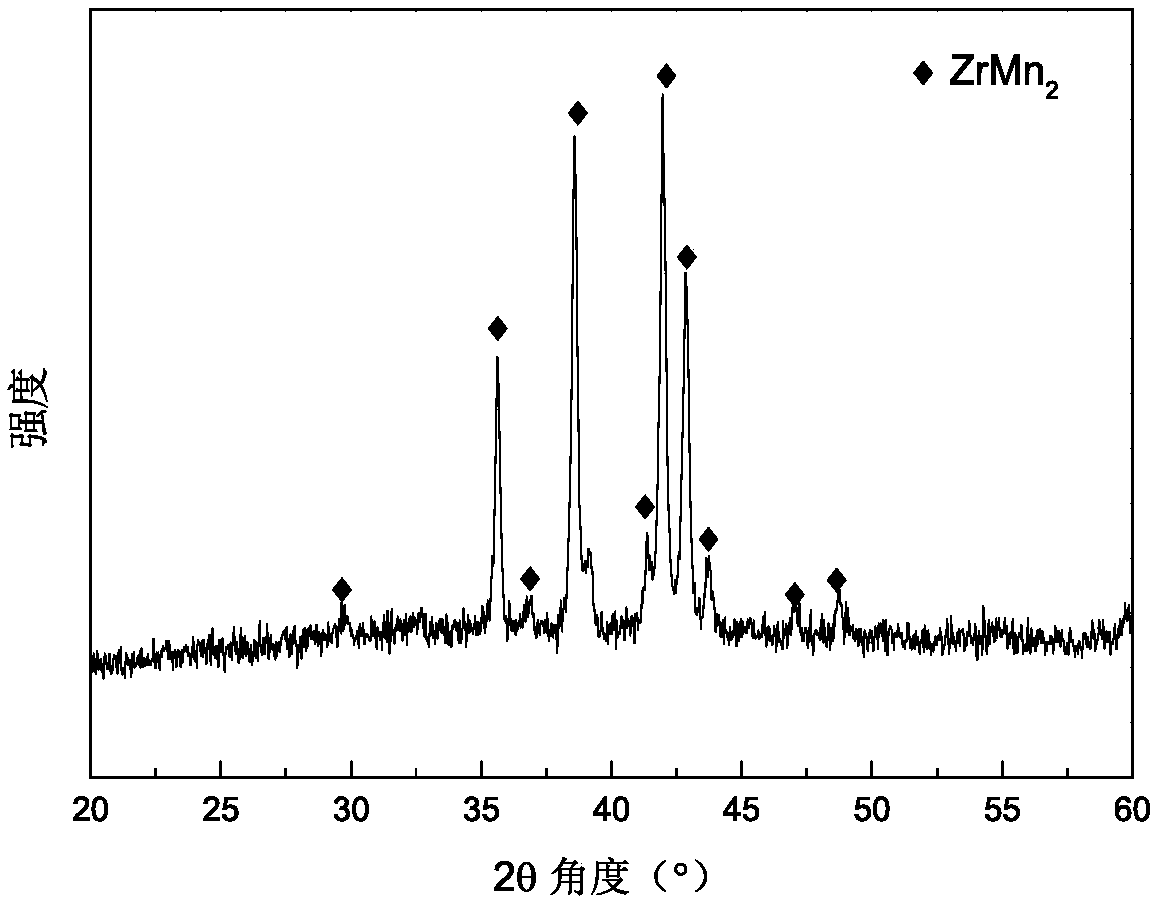

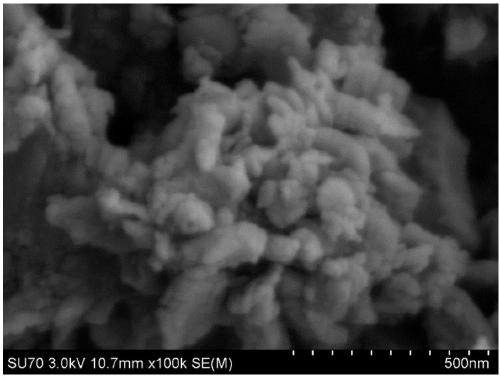

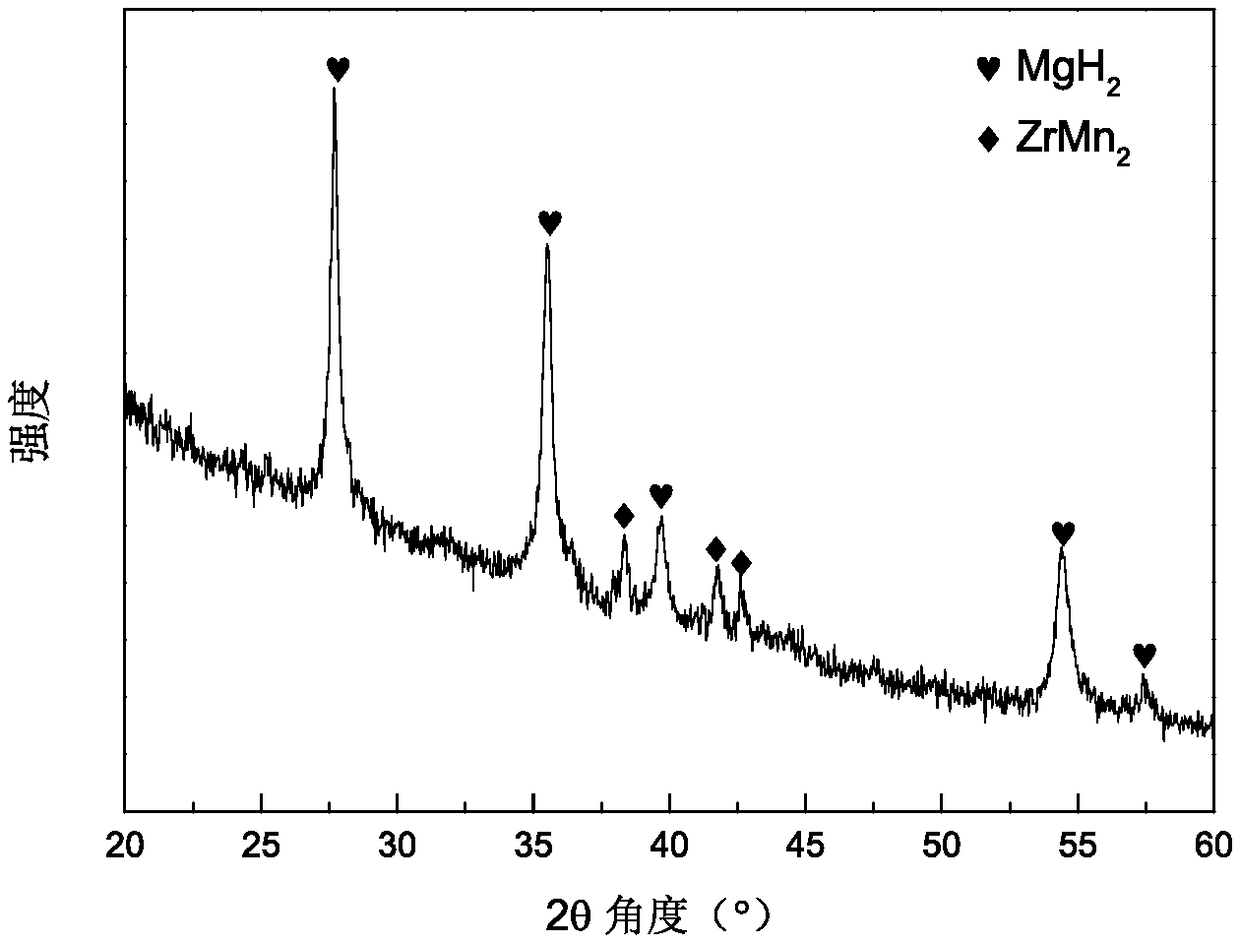

[0032] The preparation method of zirconium manganese nanoparticles is as follows:

[0033] Mix 13g of zirconium powder and 17g of manganese powder evenly and melt in a magnetic levitation melting furnace. The melting conditions in the magnetic levitation melting furnace are: melting temperature 1800°C, melting time 60 seconds, and then turn the obtained sample into a water-cooled copper crucible In the process, remelting was carried out three times to ensure that the composition of the sample was uniform, and the temperature of each remelting was 1800°C for 60 seconds. Then the smelted sample was vacuumized at 200°C for 30 minutes, cooled to room temperature, then 10 bar hydrogen pressure was added to absorb hydrogen for 20 minutes, and finally the sample was vacuumed at 200°C for 30 minutes to complete the activation. Take 2g of the activated sample, mix with 0.3ml oleic acid, 0.3ml oleylamine and 5ml heptane, and continuously ball mill at 400rpm for 30h. After the ball-mill...

Embodiment 2

[0036] The preparation method of zirconium manganese nanoparticles is as follows:

[0037] Mix 26g of zirconium powder and 34g of manganese powder evenly and melt in a magnetic levitation melting furnace. The conditions for melting in the magnetic levitation melting furnace are: melting temperature 2000°C, melting time 45 seconds, turn the obtained sample into a water-cooled copper crucible , and then remelted three times to ensure that the composition of the sample was uniform, each remelting temperature was 2000 ° C, and the time was 45 seconds. Then the smelted sample was vacuumized at 200°C for 50 minutes, cooled to room temperature, then 10 bar hydrogen pressure was added to absorb hydrogen for 30 minutes, and finally vacuumed at 250°C for 30 minutes to complete the activation. 2 g of the activated sample was mixed with 0.3 ml of oleic acid, 0.3 ml of oleylamine and 5 ml of heptane, and ball milled continuously at 450 rpm for 40 h. After the ball-milled sample was left to ...

Embodiment 3

[0040] The preparation method of zirconium manganese nanoparticles is as follows:

[0041] Mix 26g of zirconium powder and 32g of manganese powder evenly and melt in a magnetic levitation melting furnace. The melting conditions in the magnetic levitation melting furnace are: melting temperature 1900°C, melting time 50 seconds, and then turn the obtained sample into a water-cooled copper crucible In the process, remelting was carried out three times to ensure that the composition of the sample was uniform, and the temperature of each remelting was 1900°C for 45 seconds. Then the smelted sample was vacuumized at 250°C for 60 minutes, cooled to room temperature, then 15 bar hydrogen pressure was applied to absorb hydrogen for 40 minutes, and finally vacuumed at 200°C for 60 minutes to complete the activation. Take 2g of the activated sample and mix with 1ml oleic acid, 0.33ml oleylamine and 10ml heptane, and ball mill continuously at 500rpm for 20h. After the ball-milled sample ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com