Special water-based ink for tipping paper as well as preparation method and application thereof

A technology of water-based ink and tipping paper, which is applied in the field of ink, can solve problems such as hazards, and achieve the effect of improving safety and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

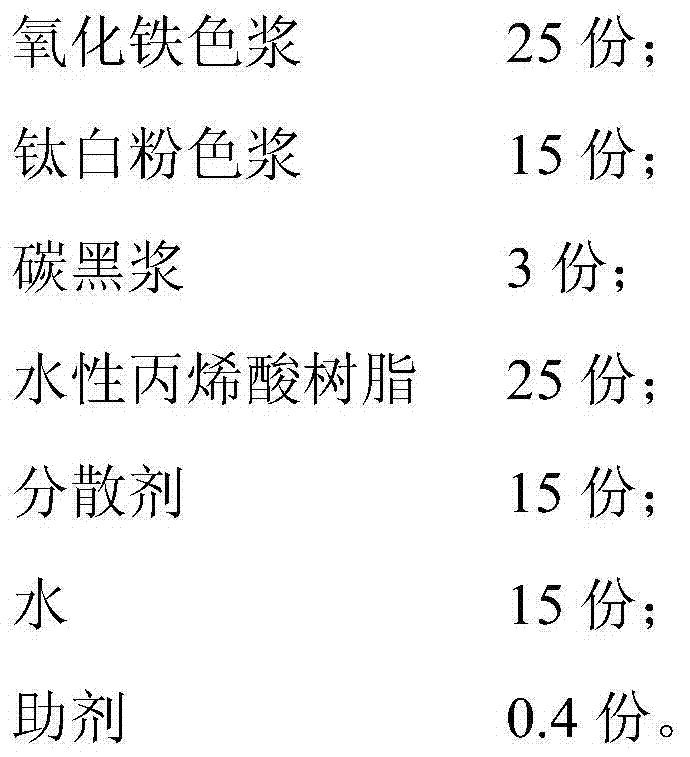

[0041] The raw material formula of water-based ink is as follows:

[0042]

[0043] The 60% iron oxide color paste and 60% titanium dioxide powder paste in the formula can be prepared as follows:

[0044] Wash 58.2 parts by weight of iron oxide or titanium dioxide, adjust the pH value to 7.0-7.5, centrifuge and dehydrate to form a filter cake with a solid content of 81%, add coupling agent, 21 parts of ammonia with a solid content of 20% Mix acrylic resin aqueous solution and 16.49 parts of water, stir, add 0.345 parts of defoamer during stirring, and then grind to an average particle size of 1-3 μm; wherein, the amount of coupling agent added is 5% of iron oxide or titanium dioxide -6% (percentage by weight).

[0045] Then prepare water-based ink as follows:

[0046] (1) Weigh the above components according to the formula ratio and grind them finely; during the fine grinding process, the temperature is 55°C, the pH value is 7.0, and the grinding time is 3 hours;

[0047...

Embodiment 2

[0052] The raw material formula of water-based ink is as follows:

[0053]

[0054] Prepare water-based ink as follows:

[0055] (1) Weigh the above components according to the formula ratio and grind them finely; during the fine grinding process, the temperature is 65°C, the pH value is 7.0, and the grinding time is 5 hours;

[0056] (2) Mix the materials obtained in step (1) evenly, add 50% benzoyl peroxide while stirring, and then gradually increase the temperature;

[0057] (3) When the temperature rises to 130°C, start to keep warm, and add the remaining benzoyl peroxide in batches, the total amount of benzoyl peroxide added is 0.2% of the total amount of each raw material component in step (1), Reflux and heat preservation for 1.5 hours; reflux heat preservation until the viscosity is 170 seconds / 25°C according to the No. 4 cup, and the acid value is 50 mgkoh / g;

[0058] (4) Cool down to 70°C, add ammonia water to ammonify to pH 7; then dilute with a mixture of etha...

Embodiment 3

[0061] The raw material formula of water-based ink is as follows:

[0062]

[0063]

[0064] Prepare water-based ink as follows:

[0065] (1) Weigh the above components according to the formula ratio and grind them finely; during the fine grinding process, the temperature is 60°C, the pH value is 7.0, and the grinding time is 4 hours;

[0066] (2) Mix the materials obtained in step (1) evenly, add 50% benzoyl peroxide while stirring, and then gradually increase the temperature;

[0067] (3) When the temperature rises to 125°C, start to keep warm, and add the remaining benzoyl peroxide in batches, the total amount of benzoyl peroxide added is 0.25% of the total amount of each raw material component in step (1), Reflux and heat preservation for 1.5 hours; reflux heat preservation until the viscosity is 160 seconds / 25°C according to the No. 4 cup, and the acid value is 45mgkoh / g;

[0068] (4) Cool down to 65°C, add ammonia water to ammonify to pH 6.5; then dilute with a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com