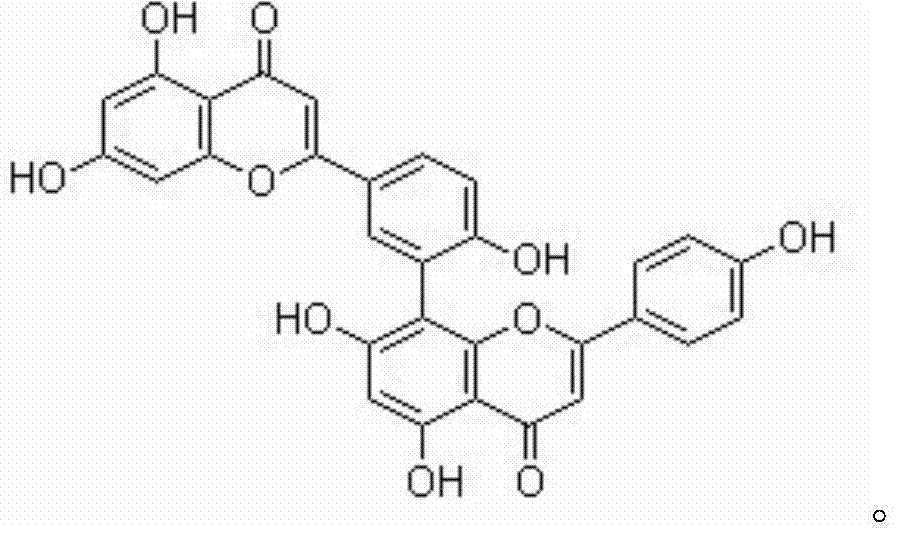

Purifying method for amentoflavone

A kind of technology of abiflavonoid and purification method, which is applied in the field of purification of abiflavonoids of Suicha, can solve the problems of large initial investment, difficult process control, high energy consumption, etc., and achieve a good effect of impurity removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Crush the raw material of Selaginella to 20-40 mesh, take 100kg, add water 8 times the weight of the raw material, heat to 80°C for extraction for 1.5h, filter, discard the filtrate, and leave the medicinal material of Selaginella;

[0024] 2) After water extraction, add 80% (v / v) ethanol of 10 times the weight of raw materials to Selaginella medicinal materials, heat and reflux for extraction for 1.5 hours, filter, and collect the filtrate; add 80% (v / v) of 7 times the weight of raw materials to the filter residue Ethanol, heated and refluxed for 1.5h, filtered, and the filtrate was collected; the filtrate was combined to obtain an extract, the extract was concentrated to recover ethanol, and then concentrated to an extract that was 1.5 times the weight of the raw material;

[0025] 3) The extract was cooled and left standing for 12 hours, centrifuged, and the filter cake was collected;

[0026] 4) crush the filter cake, add No. 6 solvent oil of 7 times the weight o...

Embodiment 2

[0029] 1) Crush the raw material of Selaginella to 20 mesh, take 200kg, add water 5 times the weight of the raw material and heat to 100°C to extract for 0.5h, filter, discard the filtrate, and leave the medicinal material of Selaginella;

[0030]2) Add 95% (v / v) ethanol 10 times the weight of the raw material to the Selaginella medicinal material after water extraction, heat and reflux for extraction for 1 hour, filter, and collect the filtrate; add 95% (v / v) ethanol 6 times the weight of the raw material to the filter residue , heating to reflux for extraction for 1 h, filtering, and collecting the filtrate; combining the filtrates to obtain an extract, concentrating the extract to recover ethanol, and then concentrating to an extract that is twice the weight of the raw material;

[0031] 3) The extract was cooled and left standing for 4 hours, centrifuged, and the filter cake was collected;

[0032] 4) Crush the filter cake, add petroleum ether degreasing in an amount 5 tim...

Embodiment 3

[0035] 1) Crush the raw material of Selaginella to 10-20 mesh, take 150kg, add water 10 times the weight of the raw material, heat to 60°C for extraction for 2 hours, filter, discard the filtrate, and leave the medicinal material of Selaginella;

[0036] 2) After water extraction, add 70% (v / v) ethanol 12 times the weight of the raw material to the Selaginella medicinal material, heat and reflux for extraction for 2 hours, filter, and collect the filtrate; add 75% (v / v) ethanol 9 times the weight of the raw material to the filter residue , heating to reflux for extraction for 2 hours, filtering, and collecting the filtrate; combining the filtrates to obtain an extract, concentrating the extract to recover ethanol, and then concentrating to an extract of 1 times the amount of raw materials;

[0037] 3) The extract was cooled and left standing for 4 hours, centrifuged, and the filter cake was collected;

[0038] 4) Crush the filter cake, add No. 6 solvent oil 10 times the weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com