Double-layer hard alloy matrix and production method thereof

A cemented carbide substrate and cemented carbide technology, applied in the field of double-layer cemented carbide substrate and its preparation, can solve the problems of unstable product performance, high production cost, poor repeatability, reliability and consistency, and achieve High repeatability of product performance, simple and controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

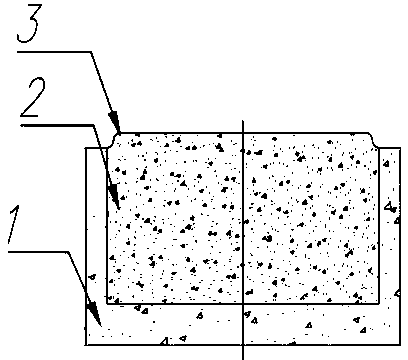

[0019] Such as figure 1 As shown, the double-layer cemented carbide substrate includes a first cemented carbide body 1 with a U-shaped structure and a second cemented carbide body 2 covered by the first cemented carbide body. The first cemented carbide body 1 is a medium-high cobalt cemented carbide, and the second cemented carbide body 2 is a medium-low cobalt cemented carbide. The second cemented carbide body 2 is convexly provided with a protruding part 3, and the shape of the protruding part 3 is a frustum of a cone, a sphere or Spherical shape, the centerline of the first cemented carbide body 1 is coaxial with the centerline of the second cemented carbide body 2, the cobalt content in the first cemented carbide body 1 is 10% to 25%, the second cemented carbide body The cobalt content in body 2 is 5% to 15%.

[0020] The preparation process of the double-layer cemented carbide substrate: first, preform a cylindrical second cemented carbide body 2 with a protrusion 3, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com