Method for determining content of silicon dioxide in rubber through spectrophotometer

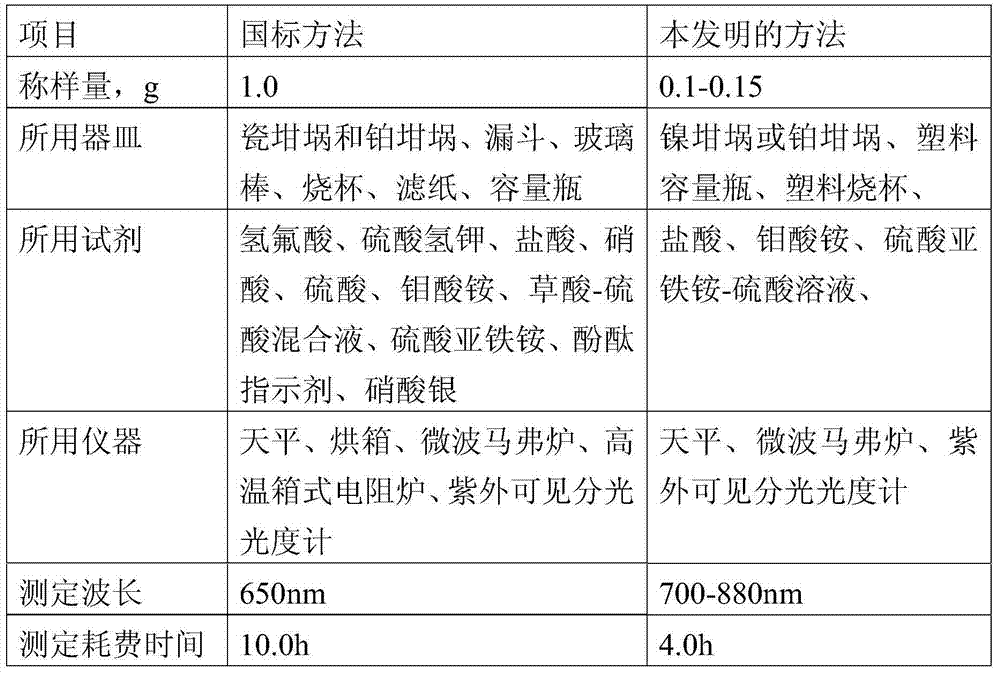

A silicon dioxide and rubber technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of high price, cumbersome operation, large error, etc., and achieve the effect of accurate and fast measurement, less sampling amount and wide measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0062] Preparation Example 1: Preparation of Vulcanized Rubber A

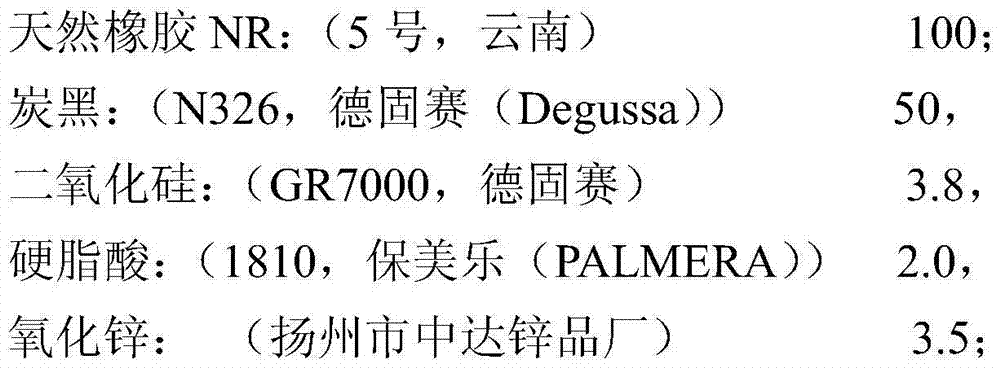

[0063] Formula 1 (parts by mass):

[0064] Component 1:

[0065]

[0066] Component 2:

[0067] Sulfur: (Puyang Flex Chemical Co., Ltd.) 1.5,

[0068] Vulcanization accelerator CZ: (Flexsys) 1.2;

[0069] Vulcanized rubber preparation process: In a 1.6-liter Banbury mixer (manufactured by FARREL), add component 1, gradually raise the temperature to 160°C and mix for 5 minutes to obtain a masterbatch, and cool the masterbatch to 90°C The following; then use the XK-160 open rubber mixer (manufactured by Qingdao Xincheng Yiming Rubber Machinery Co., Ltd.) to mix component 2 into the masterbatch, and mix the above mixture for 10 minutes at a temperature of 70°C to obtain Rubber composition; the composition obtained by the above method is molded on a BH-25T plate vulcanizer (produced by Bohai Experimental Machinery Factory, Zhenwu Town, Jiangdu District) (vulcanization temperature 160°C, vulcanization time 30...

Embodiment 1

[0070] Embodiment 1, measure the silicon dioxide content in the sample A according to the method of the present invention

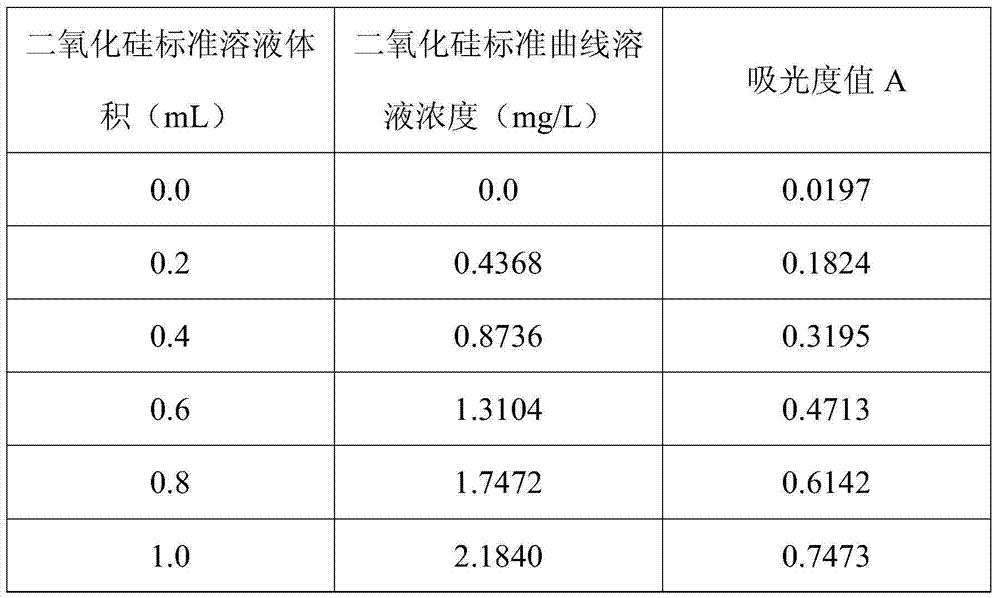

[0071] (1) Draw a standard curve

[0072] Step 1. Accurately weigh 109.2mg of reference silica into a nickel crucible, add 1g of potassium hydroxide, heat on an electric furnace until it is completely melted, add water to leaching to dissolve it, transfer it to a 100mL volumetric flask, and shake to a constant volume . The concentration of this standard stock solution is 1092mg / L.

[0073] Step 2. Accurately pipette 10 mL of silica standard stock solution, and dilute to a 100 mL volumetric flask. The concentration of this standard solution is 109.2 mg / L.

[0074] Step 3. Accurately measure 0.0, 0.2, 0.4, 0.6, 0.8, 1.0mL of silicon dioxide standard solution in a 50mL volumetric flask, add 0.85mL of 1:1 hydrochloric acid, shake well, add ammonium molybdate aqueous solution (40g / L) 5mL, shake well, stand for 15min. Then add ferrous ammonium sulfate (40g / ...

preparation Embodiment 2

[0112] Preparation Example 2: Preparation of Vulcanized Rubber B

[0113] Formula 2 (parts by mass):

[0114]

[0115]

[0116]

[0117] Component 3: Sulfur (Puyang Flex Chemical Co., Ltd.) 2.2;

[0118] Vulcanization accelerator CZ (Flex) 1.8;

[0119] Vulcanization accelerator DPG-80 (Lianyungang Lianlian Chemical Co., Ltd.) 0.75.

[0120] Vulcanized rubber preparation process: In a 1.6-liter Banbury internal mixer (produced by FARREL), add component 1, gradually raise the temperature to 160 ° C and mix for 6 minutes to obtain a section of mixed rubber, which is parked at room temperature for 20 hours; then continue to mix in Banbury. In the mixer, gradually raise the temperature to 145°C and mix the mixed rubber and component 2 for 5 minutes to obtain a masterbatch, and cool the masterbatch to below 90°C; then use XK-160 open-type rubber mixing machine (manufactured by Qingdao Xincheng Yiming Rubber Machinery Co., Ltd.) to mix component 3 into the masterbatch, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com