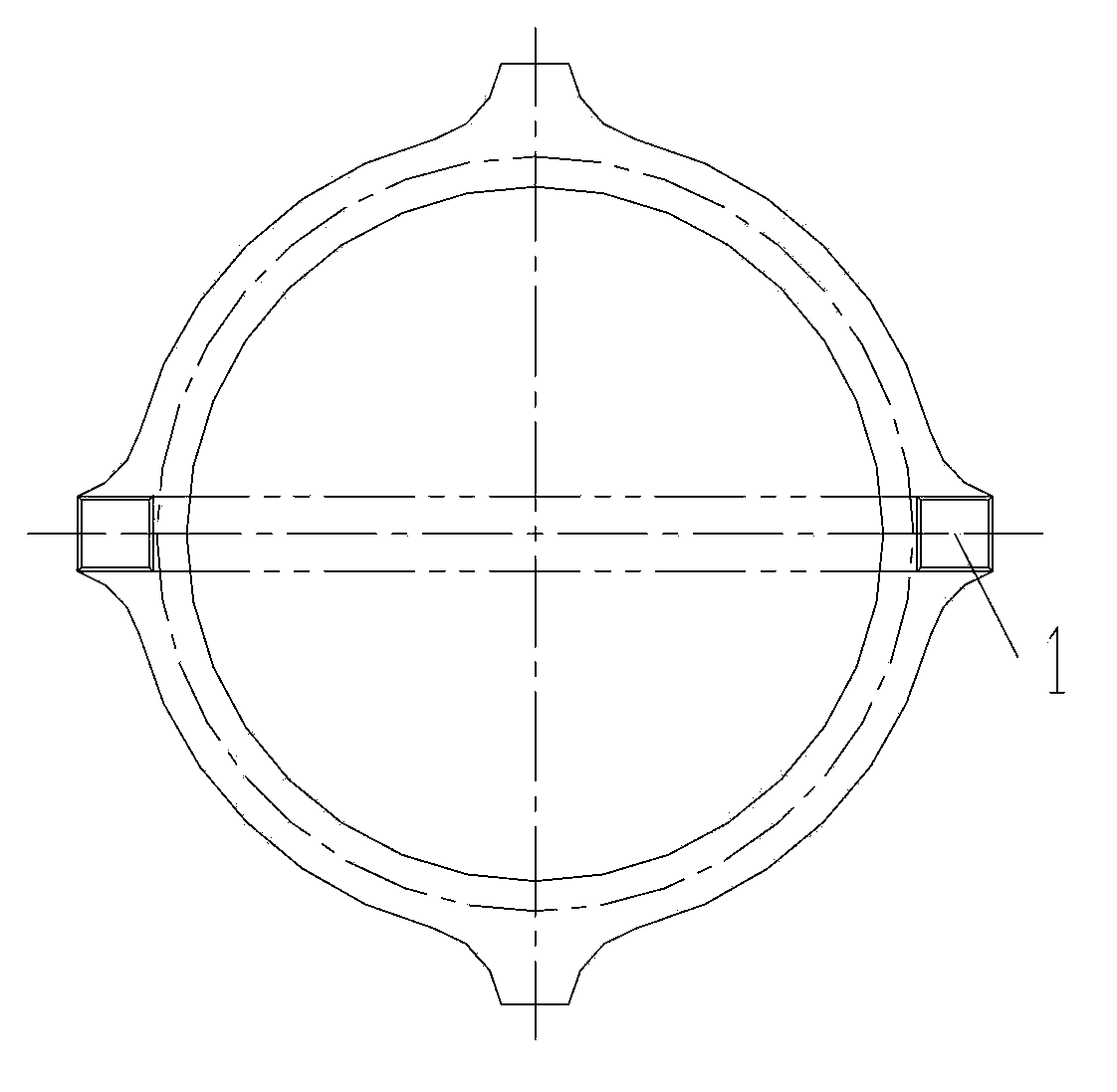

Powder metallurgy material, cross slip ring and manufacturing method of cross slip ring

A powder metallurgy, cross slip ring technology, applied in the field of metallurgy, can solve problems such as wear and tear of cross slip rings, and achieve the effects of improving wear resistance, reducing production costs and having a wide range of sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The copper powder that is 2.2% by weight, the graphite powder of 0.7%, the nickel powder of 0.5%, the molybdenum powder of 0.8%, the iron powder of 0.3% manganese powder and the iron powder of balance and weight are the above-mentioned powder metallurgy material weight 0.8% Zinc stearate is mixed to form a mixed powder; at room temperature, the mixed powder is extruded in an Oldham slip ring die to a density of 3.7g / cm with a pressing pressure of 600MPa 3 ; Sinter the extruded mixed powder at 1200°C for 60 minutes to form the Oldham slip ring blank; then pass steam into the Oldham slip ring blank at 340°C, and raise the temperature of the steam and the Oldham slip ring blank to 570°C and keep it warm 30 minutes; then the 570°C steam and the Oldham Oldham blank were cooled to 540°C, and kept at 540°C for 90 minutes to obtain the powder metallurgy Oldham Oldham of Example 1.

Embodiment 2

[0039] Mix 2.2% copper powder, 0.2% phosphorus powder, 0.7% graphite powder, 0.5% nickel powder, 0.8% molybdenum powder, 0.3% manganese powder and the rest iron powder to form a mixed powder ; Extrude the mixed powder in the Oldham slip ring mold with an extrusion pressure of 600MPa at 65°C to a density of 3.7g / cm 3 ; Sinter the extruded mixed powder at 1200°C for 60 minutes to form the Oldham slip ring blank; then pass steam into the Oldham slip ring blank at 340°C, and raise the temperature of the steam and the Oldham slip ring blank to 570°C and keep it warm 30 minutes; then the 570°C steam and the Oldham Oldham blank were cooled to 540°C, and kept at 540°C for 90 minutes to obtain the powder metallurgy Oldham Oldham ring of Example 2.

Embodiment 3

[0041] The copper powder that is 2.2% by weight, the phosphorus powder of 0.4%, the graphite powder of 0.7%, the nickel powder of 0.5%, the molybdenum powder of 0.8%, the iron powder of 0.3% manganese powder and the balance and the weight of the above powder Metallurgical materials with 0.8% zinc stearate by weight are mixed to form a mixed powder; at room temperature, the mixed powder is extruded in the Oldham slip ring die to a density of 3.7g / cm with a pressing pressure of 600MPa 3 ; Sinter the extruded mixed powder at 1200°C for 60 minutes to form the Oldham slip ring blank; then pass steam into the Oldham slip ring blank at 340°C, and raise the temperature of the steam and the Oldham slip ring blank to 570°C and keep it warm 30 minutes; then the 570°C steam and the Oldham Oldham blank were cooled to 540°C, and kept at 540°C for 90 minutes to obtain the powder metallurgy Oldham Oldham ring of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com