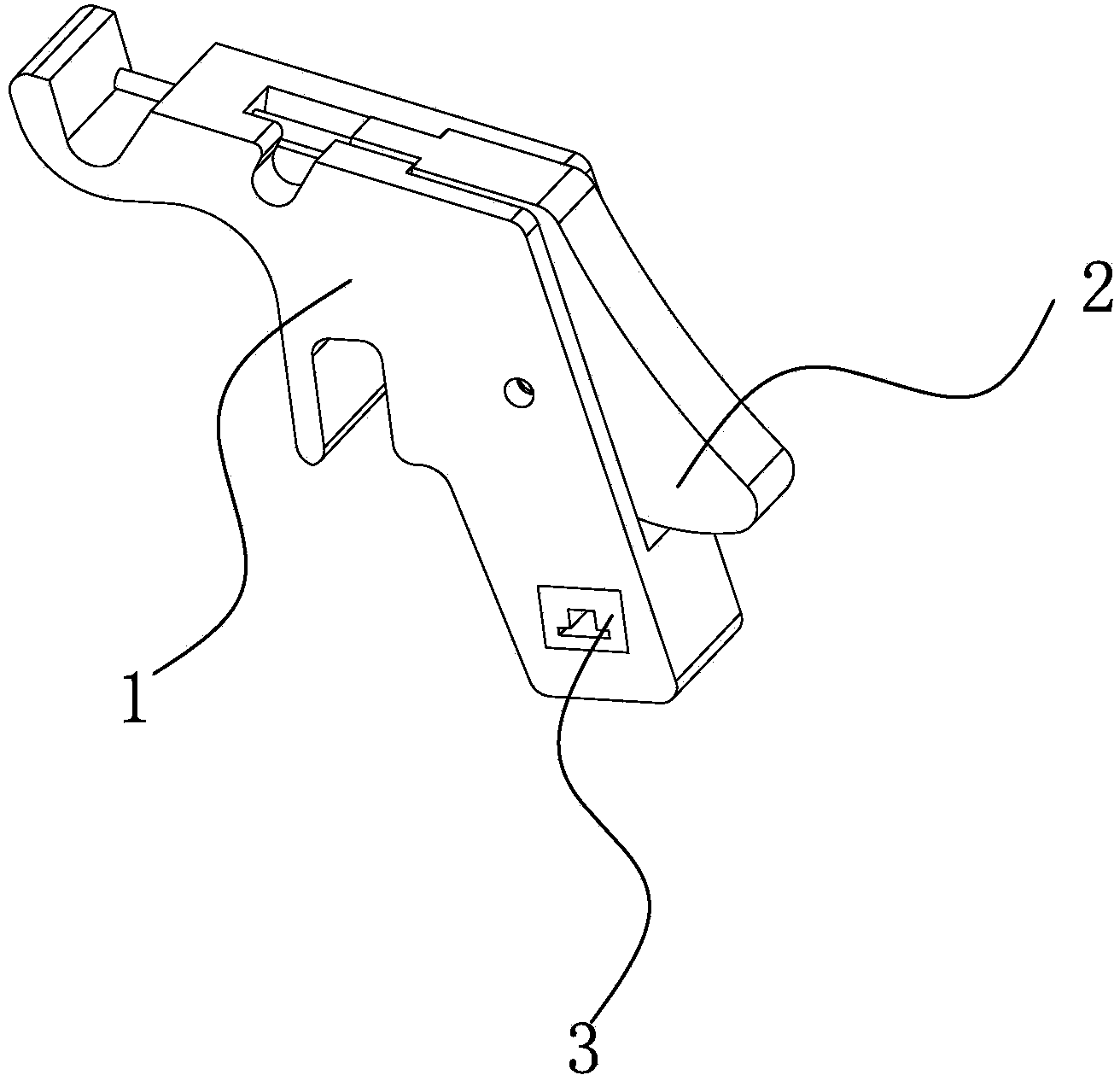

Presser foot fixer of sewing machine and preparation method thereof

A technology of presser foot and fixer, which is applied to sewing equipment, sewing machine components, presser mechanism, etc., can solve the problems of poor processing quality, high surface quality requirements, and many processing parts, etc. The effect of good quality and less process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

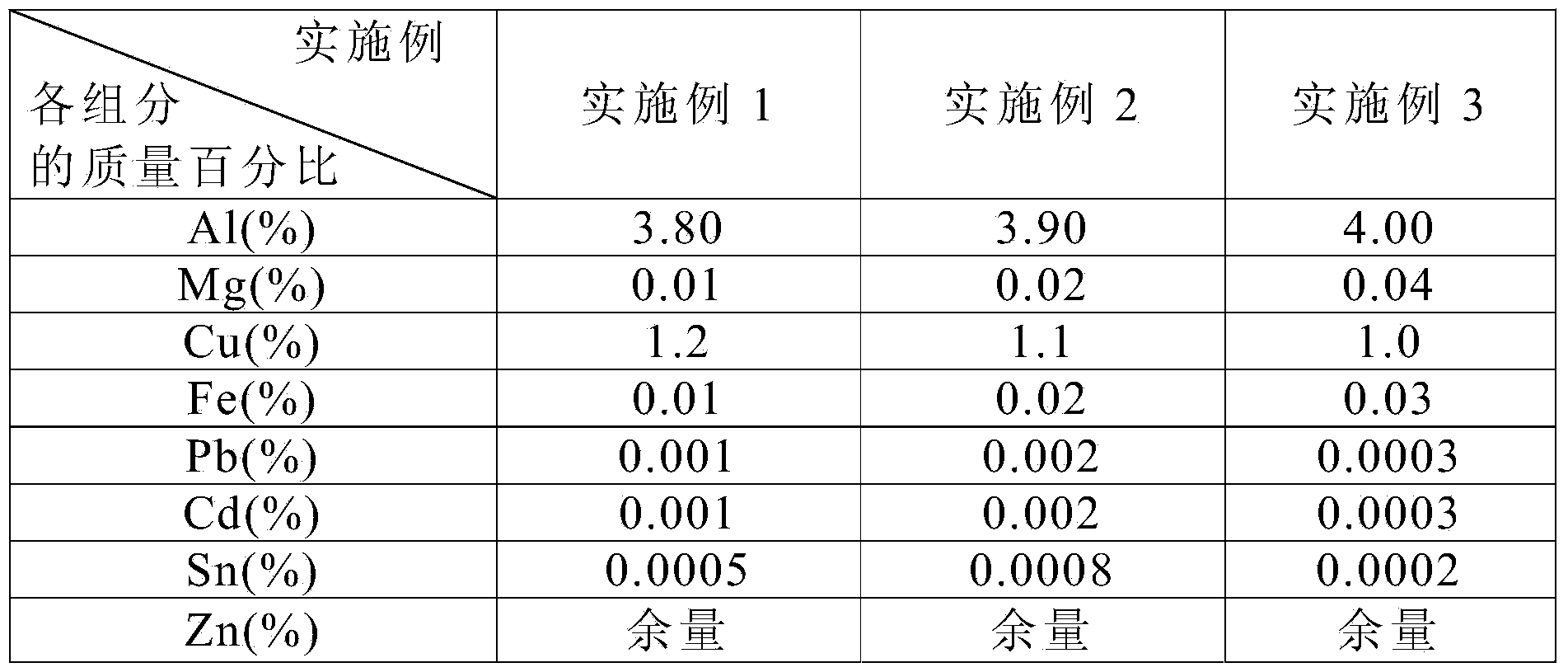

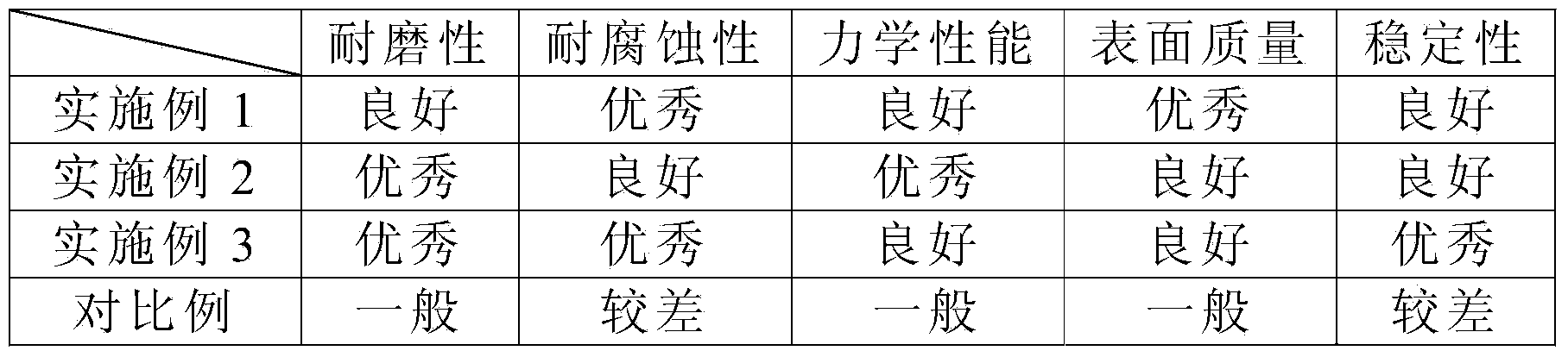

Embodiment 1

[0036] According to the components and mass percentages of Example 1 in Table 1, add aluminum, zinc, and copper into the electric furnace and heat it to 360°C to melt it. After it is completely melted, press magnesium into it with a bell jar. After the magnesium is completely melted, stir the alloy solution. , After standing still for 10min, carry out slag removal. Afterwards, the metal liquid is stamped and die-casted under the condition of a pressure of 90MPa to obtain the blank of the sewing machine presser foot holder, and then the sewing machine presser foot holder blank is subjected to finishing machining, vibration grinding, and the sewing machine presser foot holder blank Metal Cu with a thickness of 8 μm is electroplated on the surface of the blank, metal Ni with a thickness of 8 μm is electroplated on Cu, and metal Cr with a thickness of 0.3 μm is electroplated on the Ni layer. Finally, the processed sewing machine presser foot holder blank, buttons and positioning p...

Embodiment 2

[0038] According to the components and mass percentages of Example 2 in Table 1, add aluminum, zinc, and copper into the electric furnace and heat it to 380°C to melt it. After it is completely melted, press magnesium into it with a bell jar. After the magnesium is completely melted, stir the alloy solution. , carry out slag removal after standing for 5min. Afterwards, the metal liquid is stamped and die-casted under the condition of a pressure of 85MPa to obtain the blank of the sewing machine presser foot holder, and then the sewing machine presser foot holder blank is subjected to finishing machining, vibration grinding, and the sewing machine presser foot holder blank Metal Cu with a thickness of 10 μm is electroplated on the surface of the blank, metal Ni with a thickness of 9 μm is electroplated on Cu, and metal Cr with a thickness of 0.5 μm is electroplated on the Ni layer. Finally, the processed sewing machine presser foot holder blank, buttons and positioning parts ar...

Embodiment 3

[0040] According to the components and mass percentages of Example 3 in Table 1, add aluminum, zinc, and copper into the electric furnace and heat it to 400°C to melt it. After it is completely melted, press magnesium into it with a bell jar. After the magnesium is completely melted, stir the alloy solution. , After standing still for 8 minutes, carry out slag removal. Afterwards, the metal liquid is stamped and die-casted under the condition of a pressure of 88MPa to obtain the blank of the sewing machine presser foot holder, and then the sewing machine presser foot holder blank is subjected to finishing machining, vibration grinding, and the sewing machine presser foot holder blank. Metal Cu with a thickness of 12 μm is electroplated on the surface of the blank, metal Ni with a thickness of 10 μm is electroplated on Cu, and metal Cr with a thickness of 0.8 μm is electroplated on the Ni layer. Finally, the processed sewing machine presser foot holder blank, buttons and positi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com