Leaching technology for tailings clinker containing vanadium

A technology of vanadium tailings and clinker, which is applied in the field of vanadium-containing tailings clinker leaching process, which can solve the problems of long soaking time in water, increase of production cost, high content of moisture and soluble vanadium, and improve leaching efficiency and reduce particle size Requirements, the effect of shortening the leaching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 5

[0024] Embodiments one to five are specifically implemented in the following manner:

[0025] a. Ball milling: the vanadium-containing tailings clinker after sodium roasting is subjected to wet ball milling to obtain a mixture of vanadium-containing tailings clinker and water, and the wet ball mill controls 70% to 90% of the vanadium-containing tailings clinker particle size to pass through a 120 mesh sieve;

[0026] b. The mixture obtained in step a is vacuum filtered to obtain a solution and a waste residue.

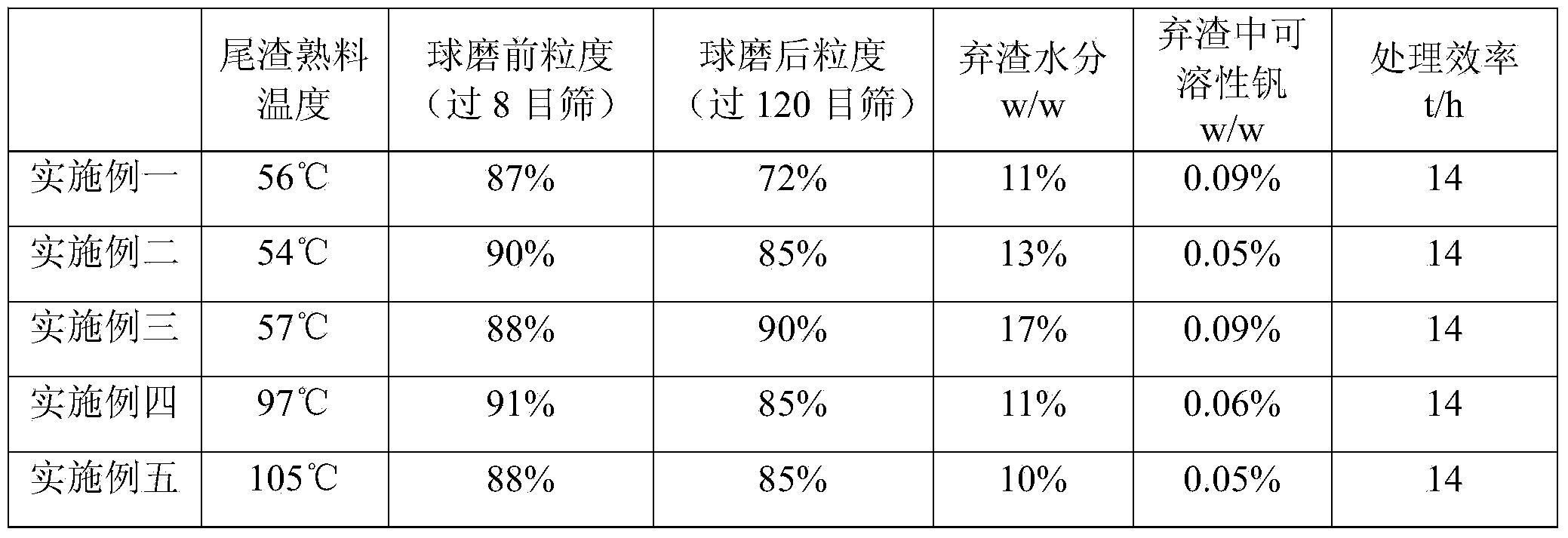

[0027] The data obtained in the above manner are shown in Table 1.

[0028] Table 1

[0029]

[0030] According to the prior art, the comparative data obtained by washing and soaking the vanadium-containing tailings clinker with tank trucks and vacuum filtration are shown in Table 2.

[0031] Table 2

[0032]

[0033] Contrast table 1 and table 2 data and can find that the present invention compares the soluble vanadium content in moisture in the obtained spoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com