Ultrasonic-assisted method for leaching potassium at low temperature under normal pressure

An ultrasonic and leaching technology, applied in the field of potassium extraction from potassium feldspar, can solve problems such as high equipment requirements, equipment corrosion, environmental pollution, etc., and achieve the effect of accelerating mass transfer, saving production costs, and making the reaction environment-friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

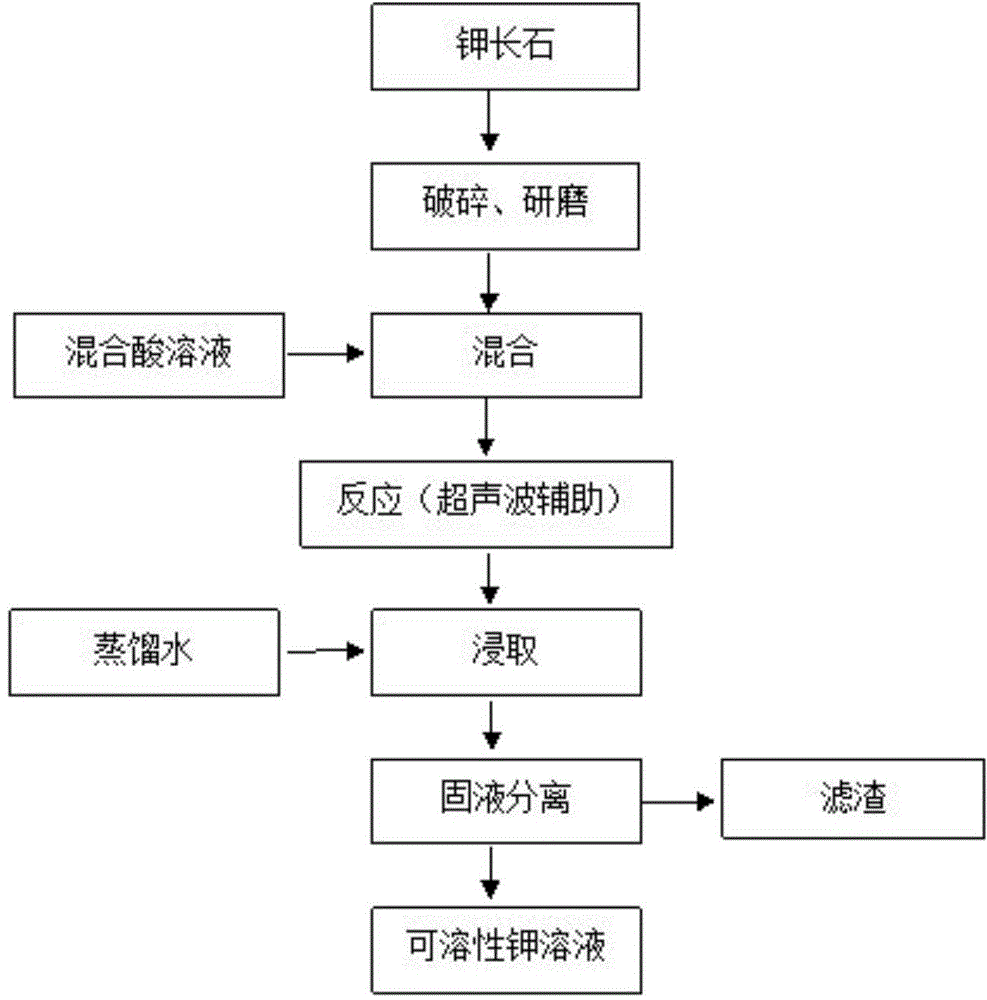

[0027] This embodiment includes the following steps:

[0028] (1) Grinding the potassium feldspar ore to a fineness of about 150 mesh;

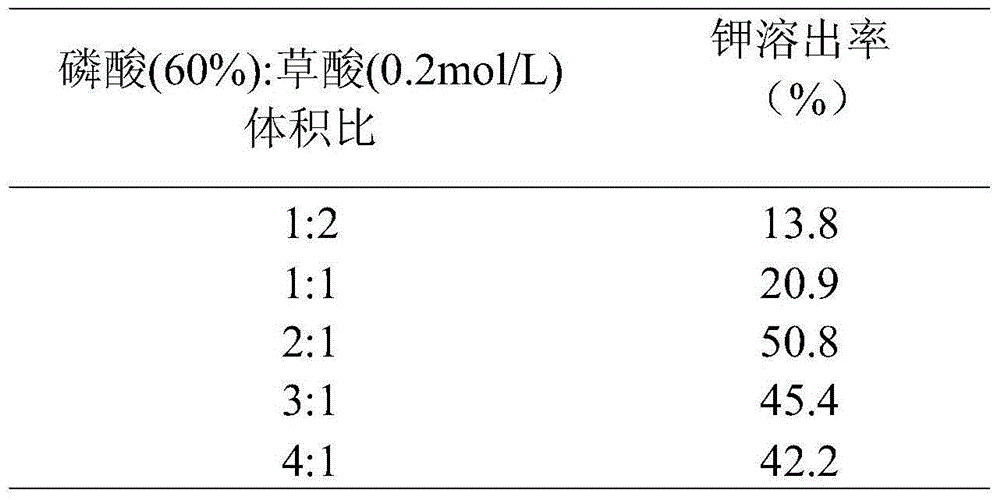

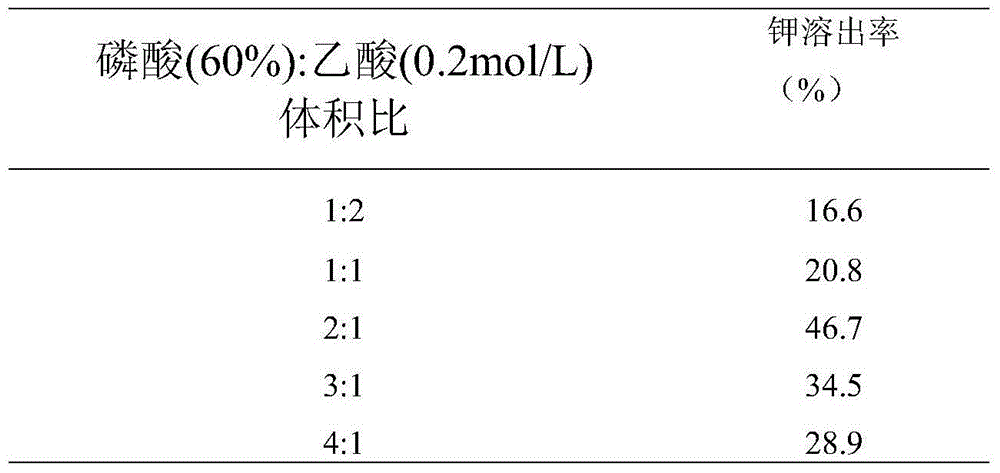

[0029] (2) Add 10 mL of mixed acid solution per gram of potassium feldspar, and mix evenly, wherein the concentration of phosphoric acid is 60%, and the concentration of oxalic acid is 0.2 mol / L;

[0030] (3) Leach the mixture obtained in step (2) under normal pressure: the reaction temperature is: 50° C., and the reaction time is 22 hours; during the reaction, ultrasonic-assisted leaching is carried out to the reaction mixture, and 40 kHz ultrasonic treatment is adopted, and the ultrasonic power is 100 W. Add water to the original volume, ultrasonic time 1h;

[0031] (4) Adding distilled water with the same volume as the mixed solution to the reacted material, leaching, and separating the solid and liquid to obtain a soluble potassium solution.

[0032] The test results show that the leaching rate of potassium after the reaction is 50.8%. ...

Embodiment 2

[0034] This embodiment includes the following steps:

[0035] (1) Grinding the potassium feldspar ore to a fineness of about 150 mesh;

[0036] (2) Add 10 mL of mixed acid solution per gram of potassium feldspar, mix well, wherein the concentration of phosphoric acid is 60%, and the concentration of oxalic acid is 0.2 mol / L;

[0037] (3) Leaching the mixture obtained in step (2) under normal pressure: the reaction temperature is: 60°C, and the reaction time is 22h; during the reaction, ultrasonic-assisted leaching is carried out to the reaction mixture, and 40kHz ultrasonic treatment is adopted, and the ultrasonic power is 100W. Add water to the original volume, ultrasonic time 1h;

[0038] (4) Adding distilled water with the same volume as the mixed solution to the reacted material, leaching, and separating the solid and liquid to obtain a soluble potassium solution.

[0039] The test results show that the leaching rate of potassium after the reaction is 41.0%.

Embodiment 3

[0041] This embodiment includes the following steps:

[0042] (1) Grinding the potassium feldspar ore to a fineness of about 150 mesh;

[0043] (2) Add 10 mL of mixed acid solution per gram of potassium feldspar, mix well, wherein the concentration of phosphoric acid is 60%, and the concentration of oxalic acid is 0.2 mol / L;

[0044] (3) Leach the mixture obtained in step (2) under normal pressure: the reaction temperature is: 50°C, and the reaction time is 30h; during the reaction, the reaction mixture is leached ultrasonically, using 40kHz ultrasonic treatment, and the ultrasonic power is 100W. Add water to the original volume, ultrasonic time 1h;

[0045] (4) Adding distilled water with the same volume as the mixed solution to the reacted material, leaching, and separating the solid and liquid to obtain a soluble potassium solution.

[0046] The test results show that the leaching rate of potassium after the reaction is 54.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com