Culm and chip mixing method and special equipment thereof

A technology of wood chips and coal slime, applied in mixers, chemical instruments and methods, peat processing, etc., can solve environmental pollution and other problems, and achieve the effects of solving environmental pollution, low cost, and stable molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be further specifically described below through specific examples.

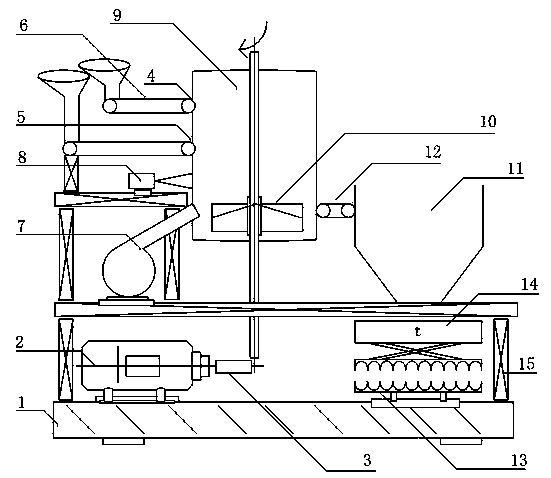

[0034] like figure 1 As shown, a coal slime and sawdust mixing molding machine includes a base (1), a motor (2), a differential (3), a coal slime feed port (4), a wood chip feed port (5), a transmission Caterpillar (6), blowing port (7), binder adding port (8), agitator (9), agitator blade (10), material storage box (11), mixed material conveying track (12), mold (13), compressor (14), machine fixing bracket (15).

[0035]Among them, the width of the coal slime feeding port is 16cm, the width of the sawdust feeding port is 16cm, the coal slime feeding port is 20cm above the sawdust feeding port, and the nozzle of the binder adding port is a porous circular nozzle with a diameter of 8cm, which can be sprayed The mist-like adhesive is released, and the adhesive addition port is 45cm below the sawdust feed port, and the diameter of the air outlet is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| body length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com