Tea polysaccharide lozenge and preparation method thereof

A technology of tea polysaccharides and tea polysaccharides, which is applied in the field of preparation of tea polysaccharide buccal tablets, can solve the problems of low production enthusiasm of tea farmers, low economic benefits of tea gardens, and influence on the development of tea industry, and achieve the goal of widening utilization channels, easy preservation, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

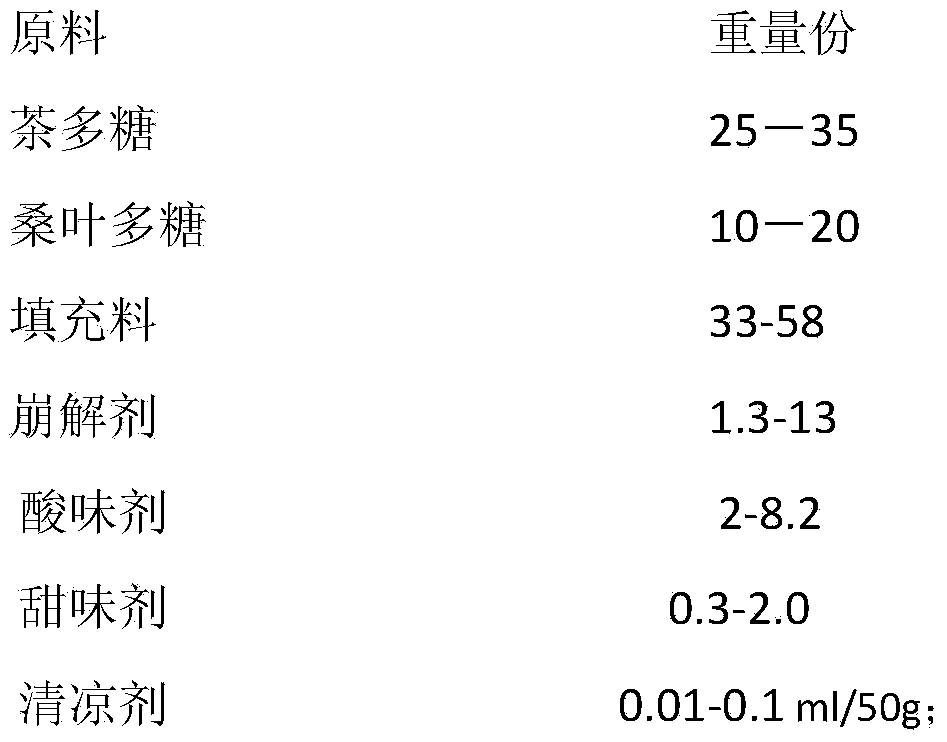

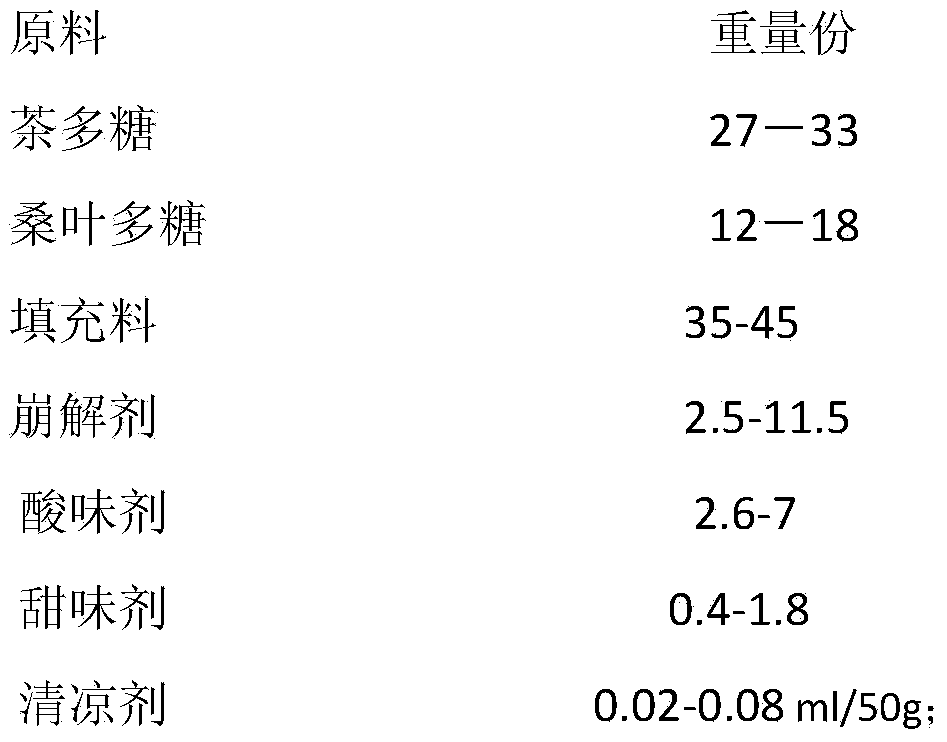

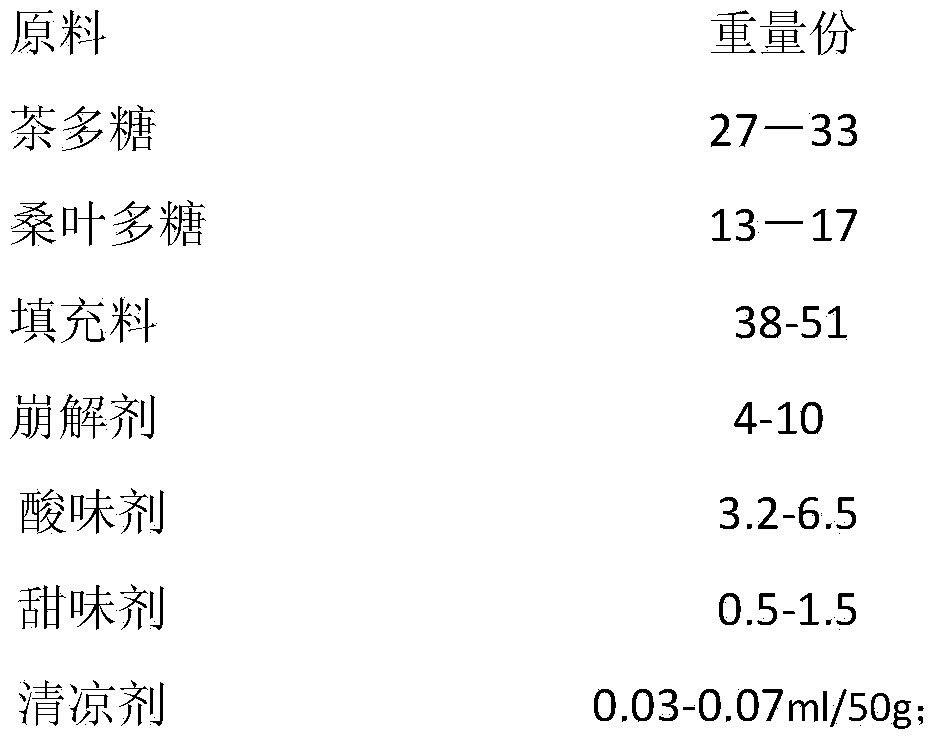

[0057] A tea polysaccharide buccal tablet, which is made of the following raw materials in parts by weight:

[0058]

[0059] The fillers are mannitol 38 and gypsum 7;

[0060] Described disintegrant is sodium carboxymethyl starch 3.5 and cross-linked polyvinylpyrrolidone 4.5;

[0061] The sour agents are citric acid 1.2 and malic acid 3.3.

[0062] A preparation method of tea polysaccharide lozenges, the steps are:

[0063] (1) Proportion of tea polysaccharide buccal tablets: including main ingredients and auxiliary materials, the main ingredients are a certain proportion of tea polysaccharides and mulberry leaf polysaccharides; A certain proportion of mannitol and a certain proportion of gypsum, the disintegrant is a certain proportion of carboxymethyl starch sodium and a certain proportion of cross-linked polyvinylpyrrolidone or a certain proportion of carboxymethyl starch sodium and a certain proportion of cross-linked polyvinylpyrrolidone, sour taste The agent is a ...

Embodiment 15

[0077] Embodiment 15: the influence of disintegrant on lozenge quality

[0078] According to the buccal tablet processing flow of mixing main and auxiliary materials, making soft materials, granulating, sieving granulating, sieving granules, and tableting, different proportions of carboxymethyl starch sodium (CMS-Na ) and cross-linked polyvinylpyrrolidone (PVPP), carboxymethylcellulose sodium (CMC-Na) and cross-linked polyvinylpyrrolidone were used as disintegrants, and a single factor experiment was carried out in which the two substances were used as disintegrants. Table 2. Other ingredients control mannitol (45-47%), tea polysaccharide (28%), mulberry polysaccharide (13.5%), citric acid (1.00%), malic acid (2.00%), aspartame (0.60%), and 80% alcohol was mixed and granulated, and finally 0.5% calcium stearate was added to press the tablet. The granule forming rate, hardness, disintegration time limit, and friability were analyzed as indicators to determine the optimal ratio...

Embodiment 16

[0086] Example 16: Effect of fillers on lozenge quality

[0087] Mannitol and gypsum are selected as fillers according to the lozenge processing flow of mixing main and auxiliary materials, making soft materials, granulating, sieving granulating, sieving granules, and tableting. The mannitol and gypsum with the content of 0-45% in different ratios are used as the ratio to carry out the screening test of the filler. The amount of other excipients is controlled CMS-Na (3.0%), PVPP (5.0%), tea polysaccharide (28%), mulberry polysaccharide (13.5%), citric acid (1.0%), malic acid (2.0%), aspartame (0.6%), mixed and granulated with 80% alcohol, and finally added 0.5% calcium stearate to compress the tablet, and analyzed the results with the granule forming rate, hardness, disintegration time limit, and friability as indicators, combined with the taste score, to determine The optimal ratio of filler mannitol and gypsum was used, and the test was repeated 3 times. When different rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com