Lithium ion battery anode material and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, which is applied in the field of new lithium-ion battery positive electrode materials and its preparation, can solve problems such as long operating time, uneven mixing, difficult carbon coating, etc., and achieve the effect of avoiding metal reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

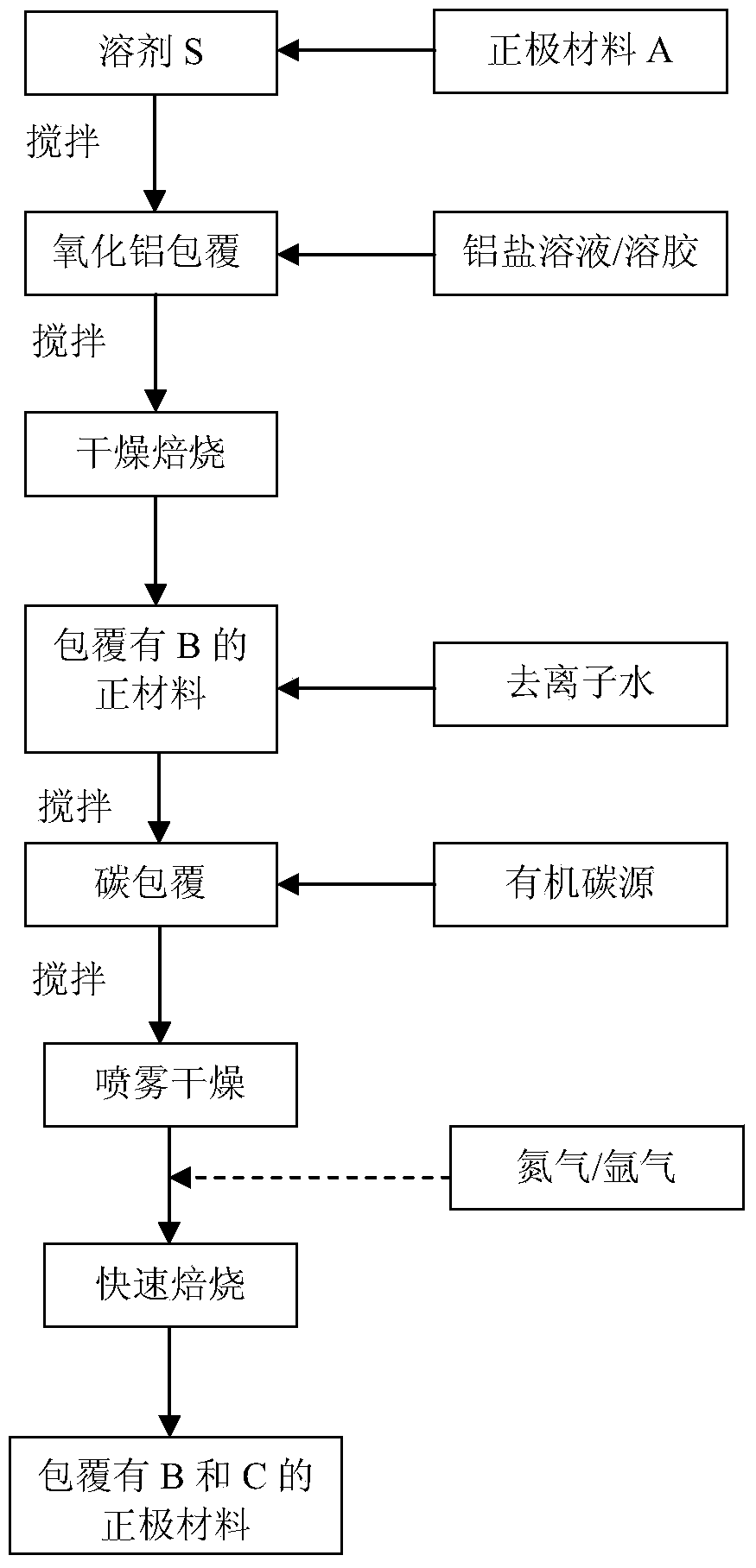

[0033] The specific embodiment of the preparation method of lithium ion battery cathode material of the present invention, the process flow chart of described method is as attached figure 1 As shown, the method specifically includes the following steps:

[0034] (1) Synthesize the existing lithium-ion battery positive electrode material A by a conventional method. Specifically, the existing lithium-ion battery positive electrode material A may be lithium cobaltate positive electrode material; nickel, cobalt, manganese binary or ternary positive electrode material; manganic acid Lithium cathode materials (including layered doped lithium-rich lithium manganate, spinel lithium manganate);

[0035] (2) Prepare lithium-ion battery positive electrode material A and solvent S at a mass ratio of 0.5:1 to 5:1 to make a slurry, and gradually add it at a rate of 1 to 20mL / min under constant stirring to a concentration of 10% ~50% aluminum monoacetate or aluminum diacetate solution, the ...

Embodiment 1

[0041] A kind of embodiment of the preparation method of a kind of lithium ion battery cathode material of the present invention, the method described in this embodiment comprises the following steps:

[0042] (1) Weigh 2000g of LiCoO synthesized by conventional method 2 Positive electrode material A, add 1000g deionized water 1500r / min speed and fully stir, and add 331.20g containing 33.12g (CH 3 COO) 2 The solution of AlOH, after dropwise addition, continued to stir for 3 hours, and stopped stirring;

[0043] (2) Filtrate and dry at 80°C for 20 hours, pass through a 200-mesh sieve, and then bake the dried powder in a muffle furnace at 500°C in an air atmosphere for 5 hours, and cool naturally to obtain LiCoO coated with an alumina layer B on the outer surface 2 Cathode material;

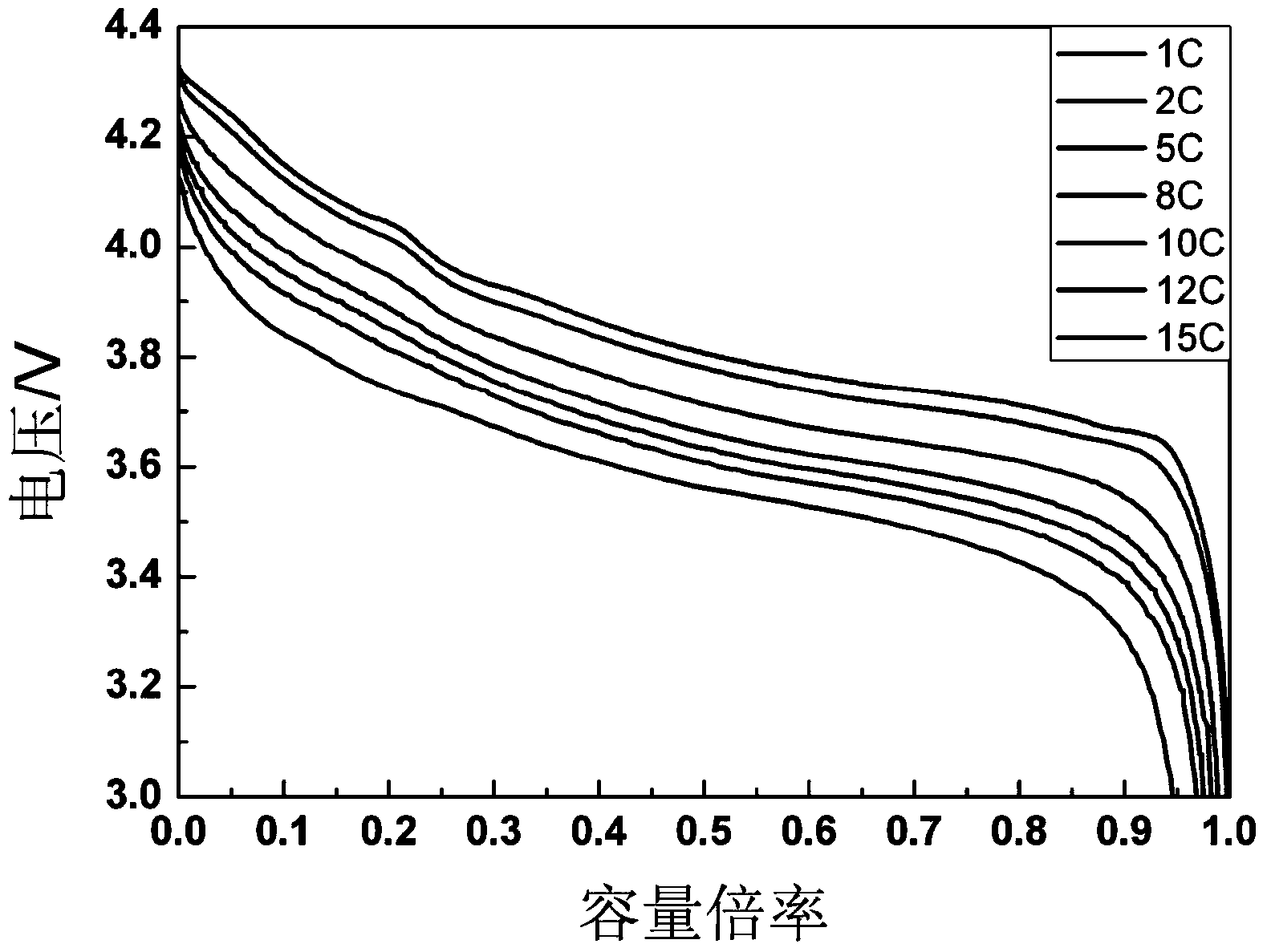

[0044] (3) 2000g of LiCoO coated with alumina layer B on the outer surface 2 The positive electrode material and 1000g of water are prepared into a mixed solution, and 200g of sucrose is added ...

Embodiment 2

[0048] A kind of embodiment of the preparation method of a kind of lithium ion battery cathode material of the present invention, the method described in this embodiment comprises the following steps:

[0049] (1) Weigh 2000g of LiCoO synthesized by conventional method 2 Positive electrode material A, add 500g deionized water and stir at a speed of 2000r / min, and add 101.40 containing 50.70g CH 3 COOAl(OH) 2 The solution, after the dropwise addition, continued to stir for 4 hours, and stopped stirring;

[0050] (2) Filtrate and dry at 100°C for 24 hours, pass through a 200-mesh sieve, then bake the dried powder in a muffle furnace at 600°C in an air atmosphere for 8 hours, and cool naturally to obtain LiCoO coated with an alumina layer B on the outside 2 Cathode material;

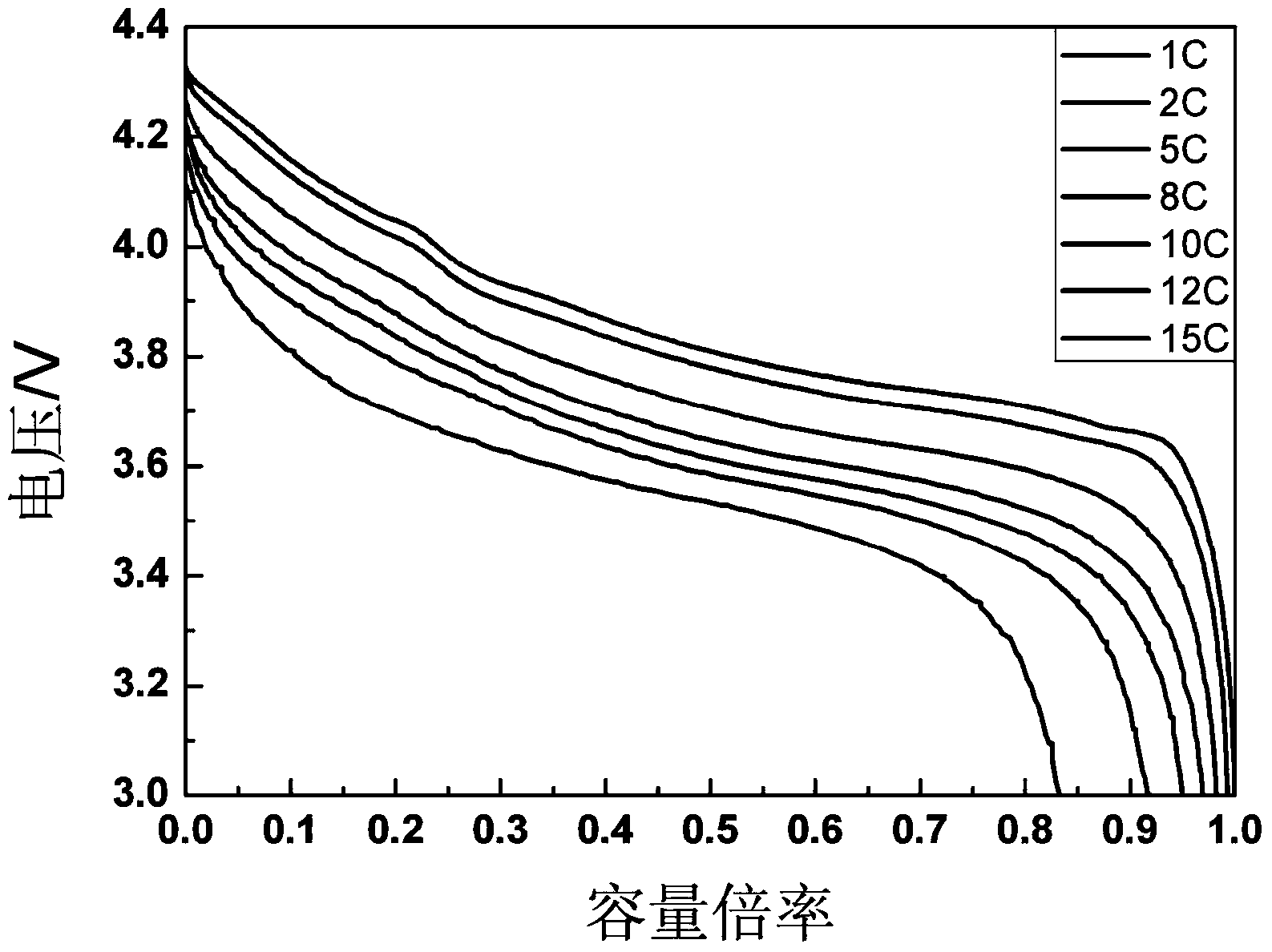

[0051] (3) 2000g of LiCoO coated with alumina layer B on the outer surface 2 The positive electrode material and 1000g of water are prepared into a mixed solution, and 400g of sucrose is added to the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com